Miniature heating equipment liquid supplementation device

The technology of a liquid replenishing device and equipment is applied in the field of liquid replenishing device for micro heating equipment, which can solve the problems of equipment and circulating pipelines freezing, unstable pressure, and pressure reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

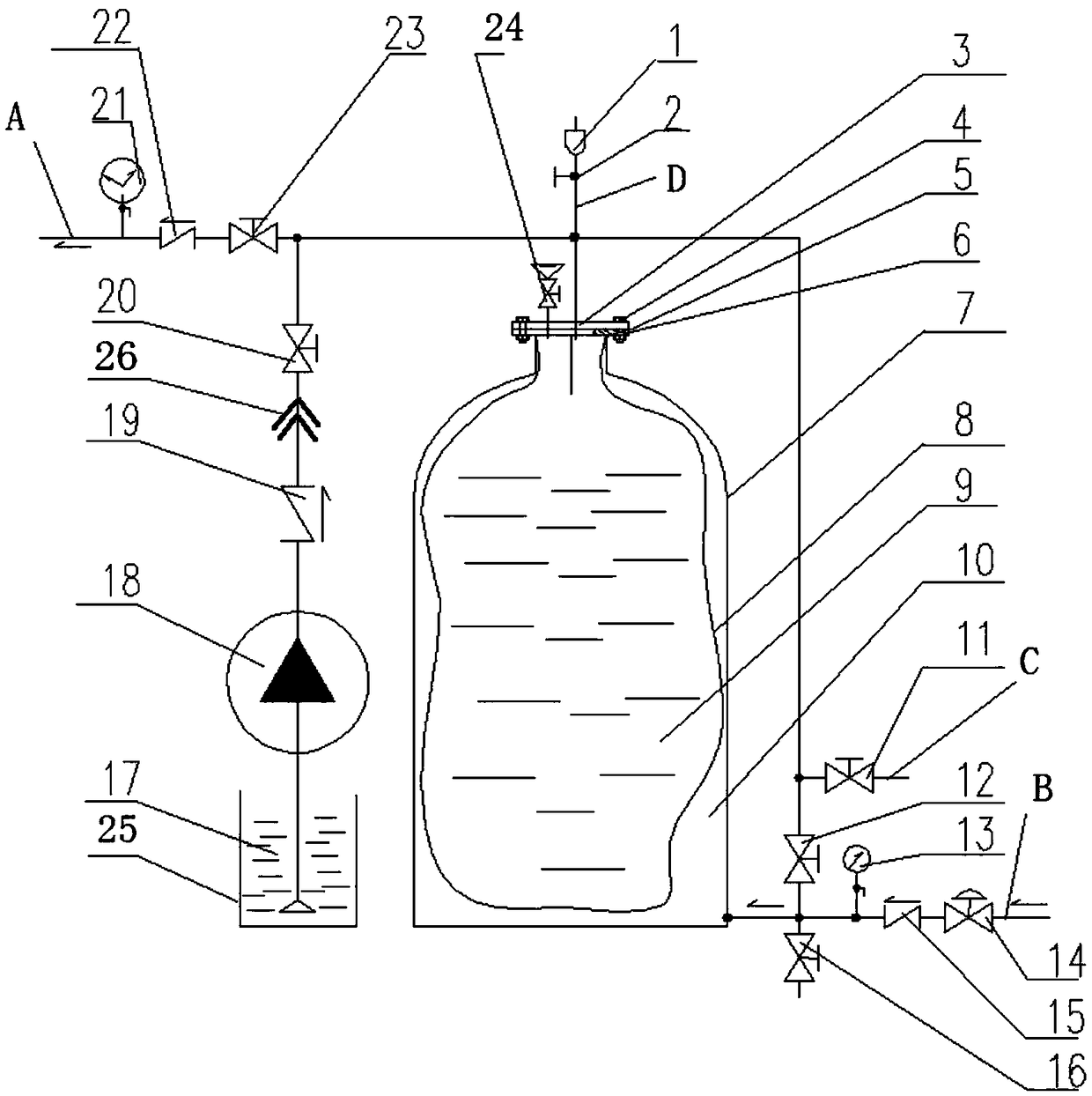

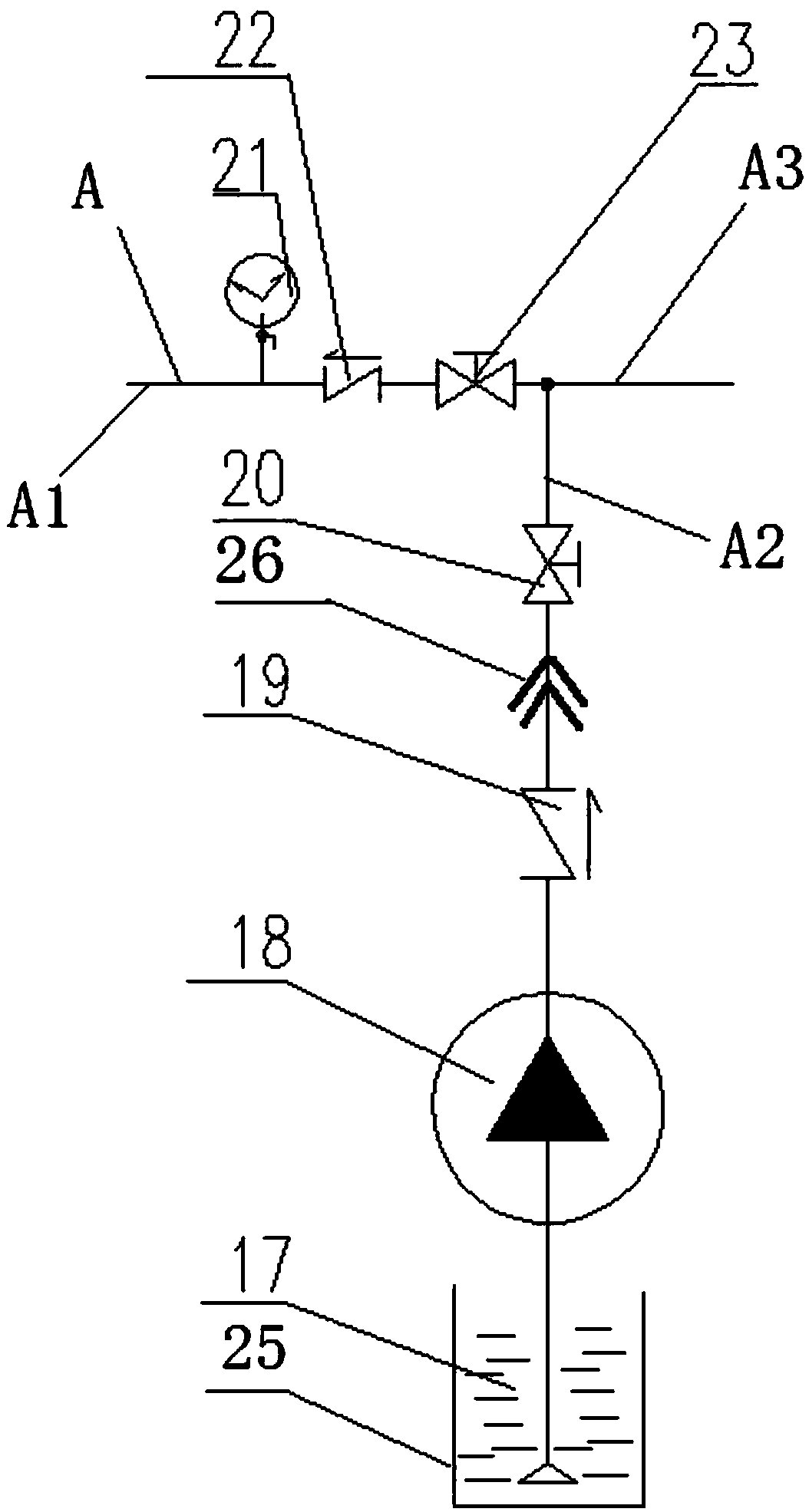

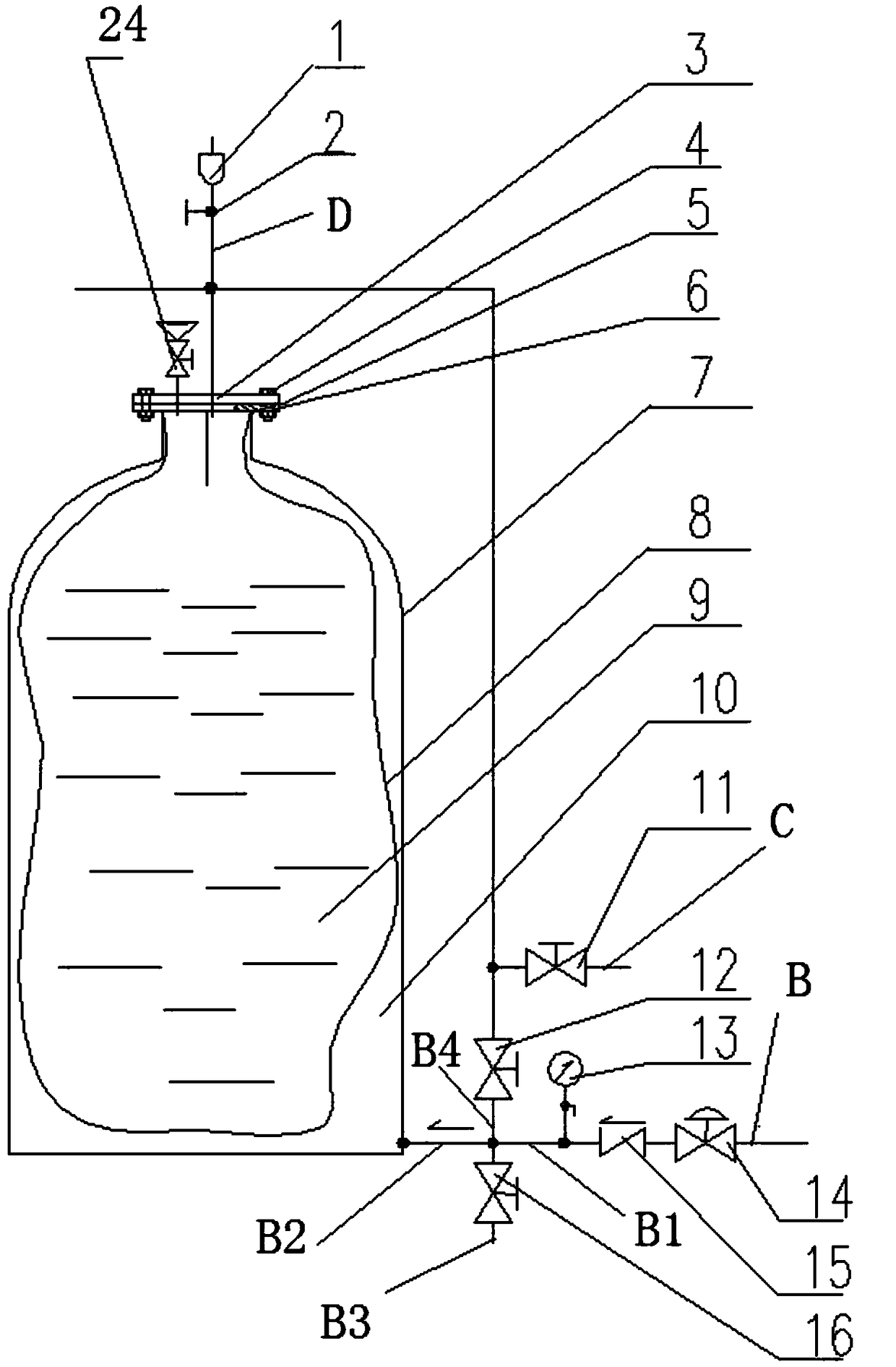

[0043] See figure 1 , figure 2 as well as image 3 , The first embodiment of the present invention provides a micro-heating equipment liquid supplement device, including an antifreeze output pipe A and a tap water supply pipe B;

[0044] Wherein, the antifreeze output pipeline A includes a main antifreeze output pipeline A1 and two infusion pipelines branched from the main antifreeze output pipeline A1, namely, a first infusion pipeline A2 and a second infusion pipeline A3 ; The main antifreeze output pipeline A1 is connected to the circulating system (that is, the arrow at the antifreeze output pipe A indicates the direction in which the antifreeze enters (and connects) to the subsequent circulation system; in addition, the arrow at the tap water supply pipe B indicates the direction in which the tap water enters );

[0045] Wherein, the first infusion pipeline A2 is connected with the replenishing booster pump 18 and the antifreeze containing barrel 25; the antifreeze containin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com