Engine thermal management system

A thermal management system and engine technology, applied in the cooling of engine components, machines/engines, engines, etc., can solve the problem of difficult to meet engine power, economy and emission requirements, poor heat transfer effect of oil cooler, single cooling Circuit and other issues to achieve the effect of optimizing engine performance, improving engine performance, and reducing exhaust temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

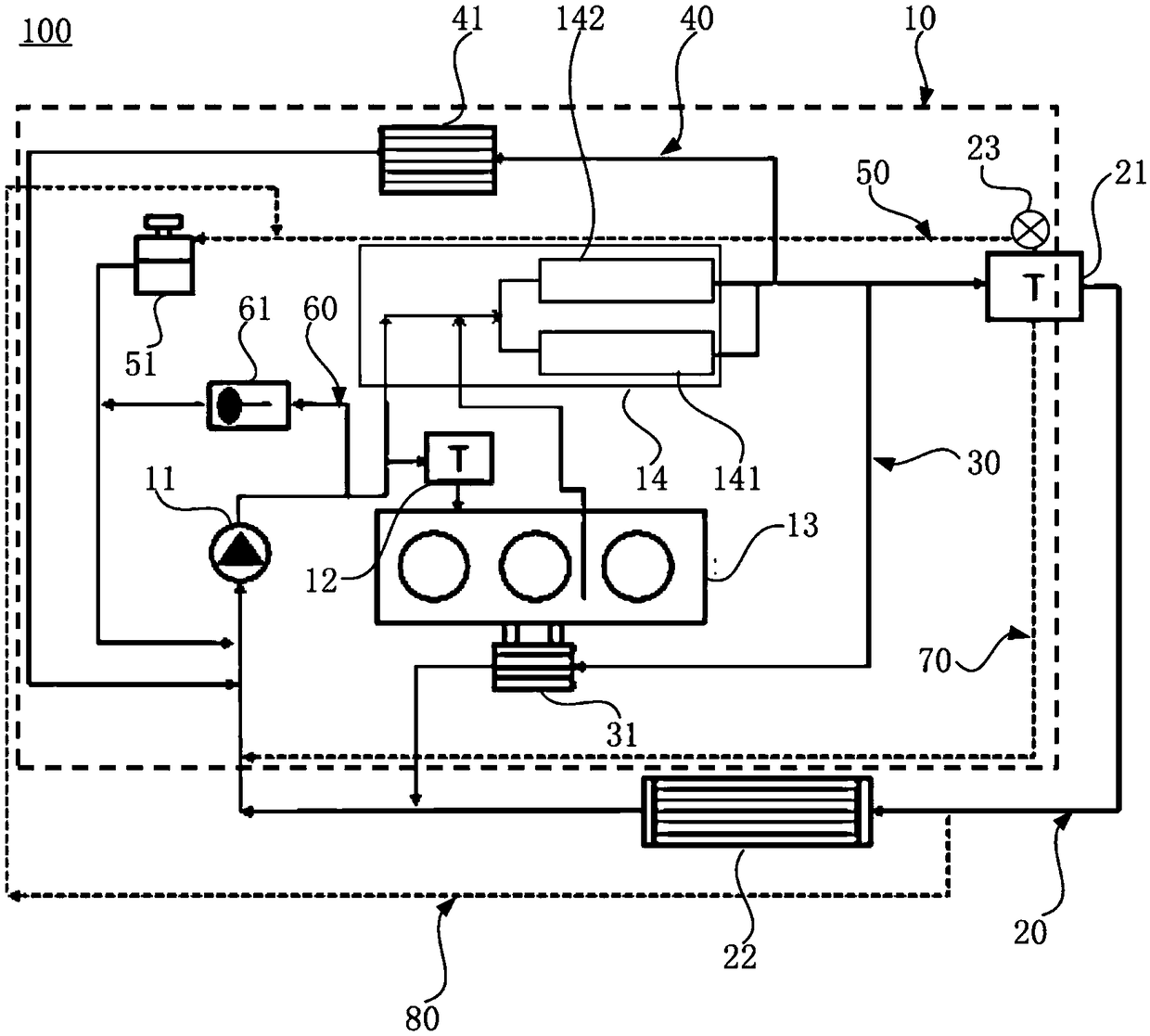

[0030] figure 1 is a schematic diagram of an engine thermal management system 100 according to one embodiment of the present invention. The engine thermal management system 100 of this embodiment may generally include a first circulating cooling circuit 10 and a second circulating cooling circuit 20 . Wherein, the first circulating cooling circuit 10 may include a mechanical water pump 11, a cylinder body valve 12, a cylinder body water jacket 13 and a cylinder head water jacket 14 connected in series by pipelines, wherein, before the cylinder body valve 12, the mechanical water pump 11 also It can be directly connected with the cylinder head water jacket 14 through pipelines, so that when the temperature of the coolant is lower than the first preset temperature, the cylinder block valve 12 is closed, and the coolant pumped from the mechanical water pump 11 directly enters the cylinder head water jacket 14 and Circulate back to the mechanical water pump 11. When the temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com