Washing machine

A technology of a washing machine and an outer tub, applied in the field of washing machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] This embodiment provides a washing machine. The washing machine mentioned in this embodiment may be a drum washing machine or a pulsator washing machine. This embodiment takes a drum washing machine as an example.

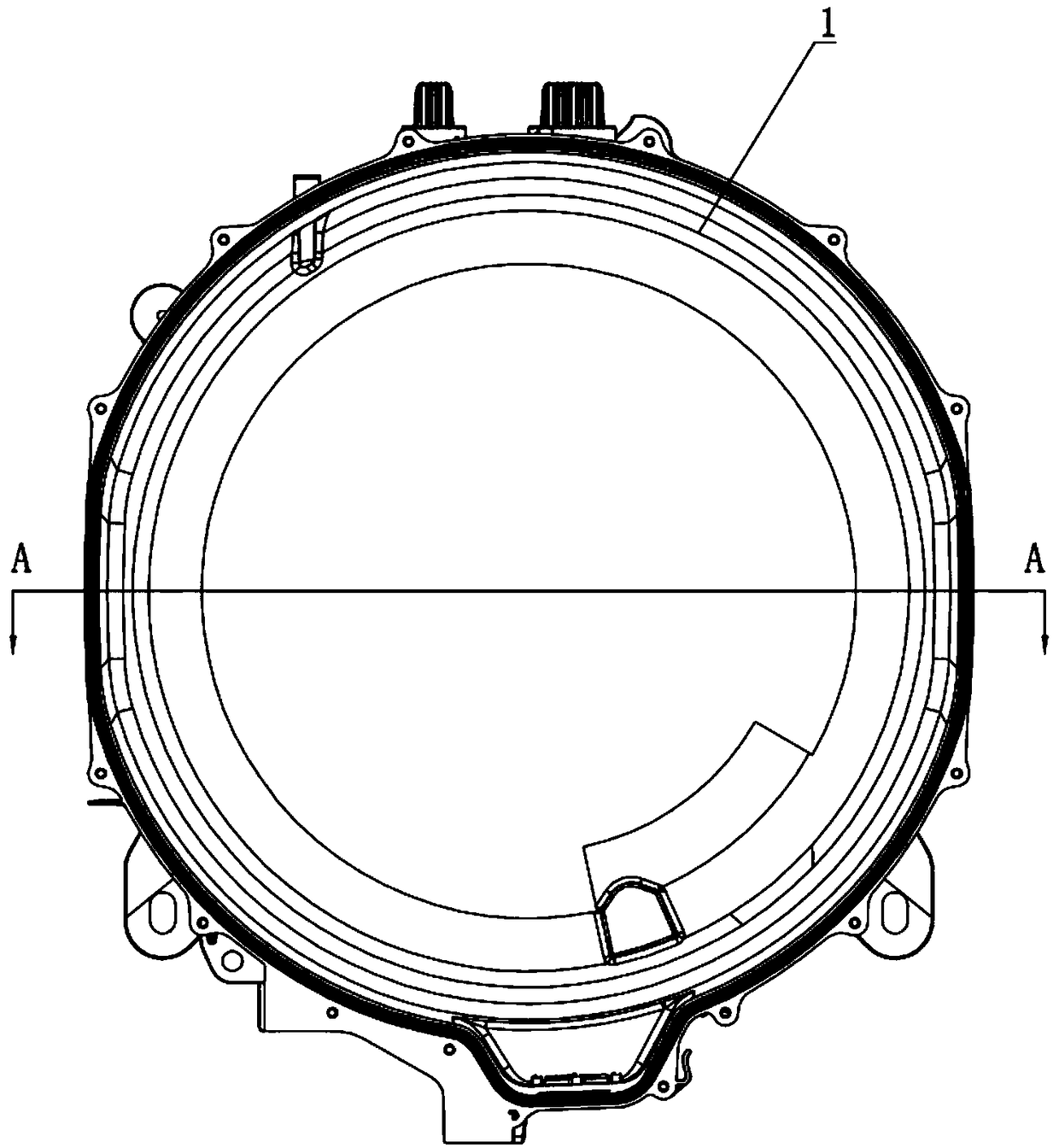

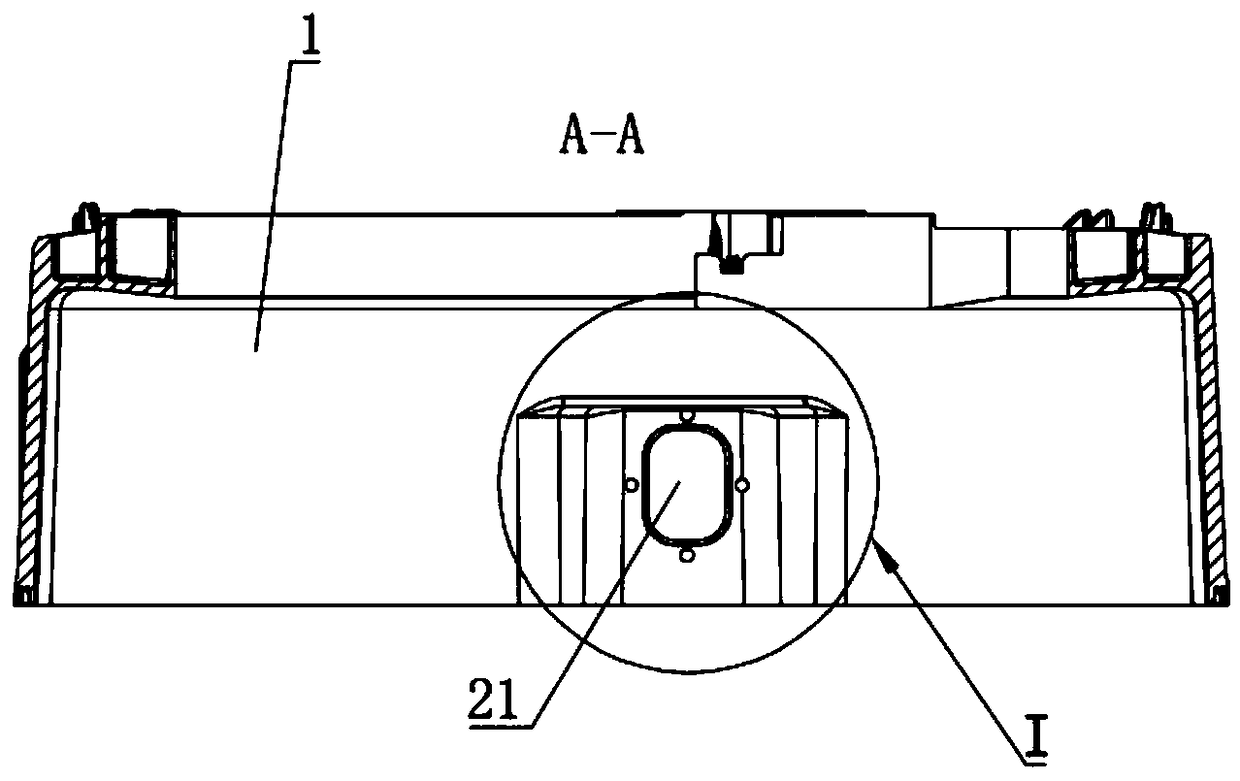

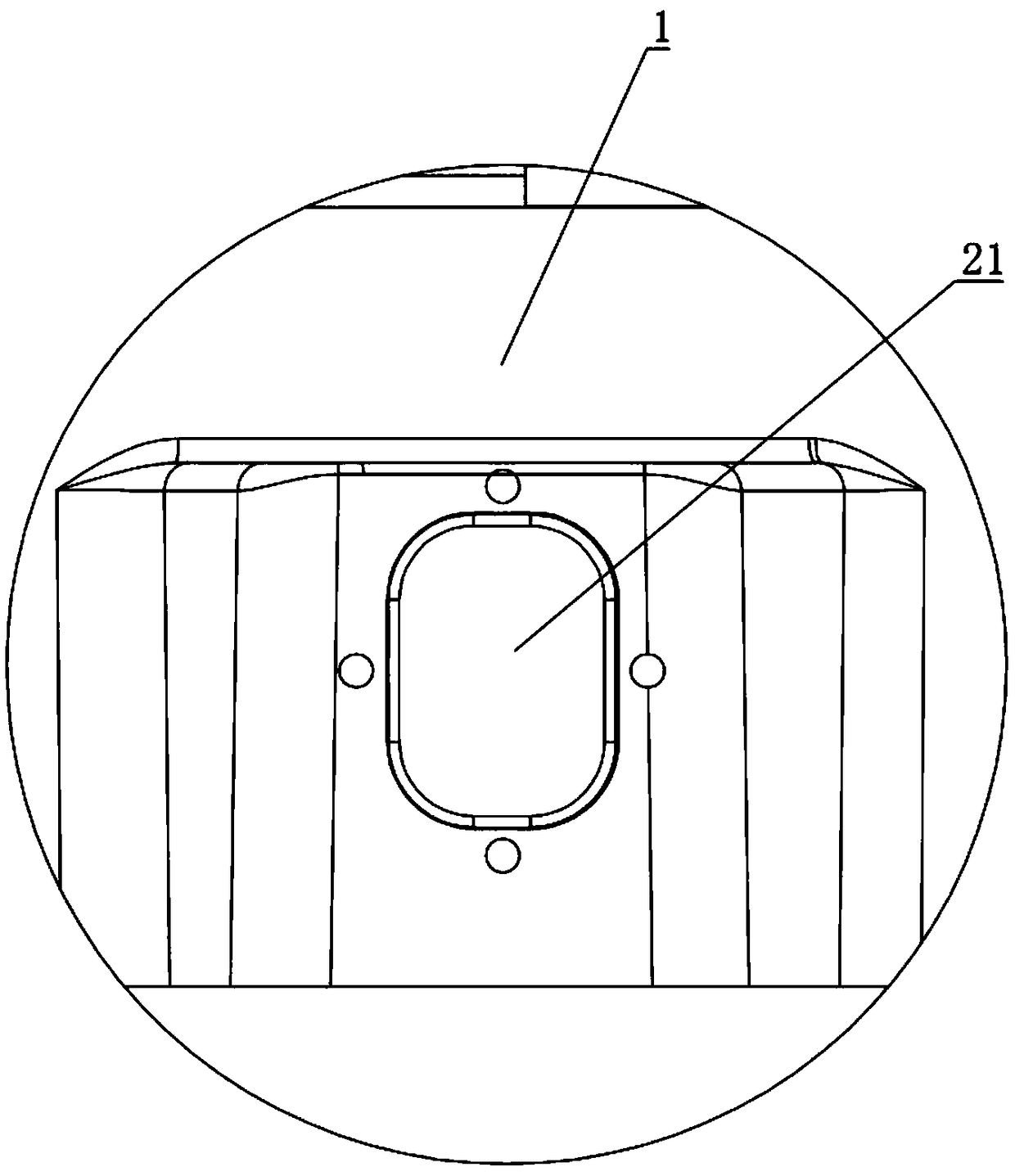

[0031] Such as Figure 1 to Figure 4 As shown, the washing machine includes an outer cylinder 1 and a heater 2 connected to the outer cylinder 1. One end of the heater 2 is placed between the outer cylinder 1 and the inner cylinder of the washing machine and connected to the heating of the outer cylinder 1. The heater body 21 is connected to the heater body 21 placed on the outer end of the outer cylinder 1 and used for heating the heating substrate 22, and a controller electrically connected to the heating substrate 22; the heater body 21 Made of thermally conductive material.

[0032] The heater 2 described in this embodiment cancels the installation bracket, and adopts the heater body 21 to pass through the outer cylinder 1, so that one end of the heater...

Embodiment 2

[0047] The difference between the washing machine of this embodiment and the washing machine described in Embodiment 1 is that the structure of the heating base 22 is different, such as Figure 5 As shown, the heating base 22 in this embodiment includes an inner insulating medium layer 221, a resistance heating layer 222 and an outer insulating medium layer 223 arranged in sequence along the direction from the inside of the outer cylinder 1 to the outside of the outer cylinder 1. ; The end of the heater body 21 placed outside the outer cylinder 1 is connected to the inner insulating medium layer 221 ; the inner insulating medium layer 221 is made of thermally conductive material.

[0048] The controller is used to control the heating base 22 to work, and heat is generated through the resistance heating layer 222. The heat generated by the resistance heating layer 222 is transferred to the heater body 21 through the inner insulating medium layer 221, and then transferred to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com