Method for fermenting biological antibacterial molasses alcohol

A molasses alcohol fermentation and biological technology, applied in the direction of fermentation, etc., can solve the problems of low fermented alcohol content and low feeding brix, and achieve the effects of increasing alcohol content, reducing waste liquid discharge, and rapidly and efficiently fermenting alcohol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

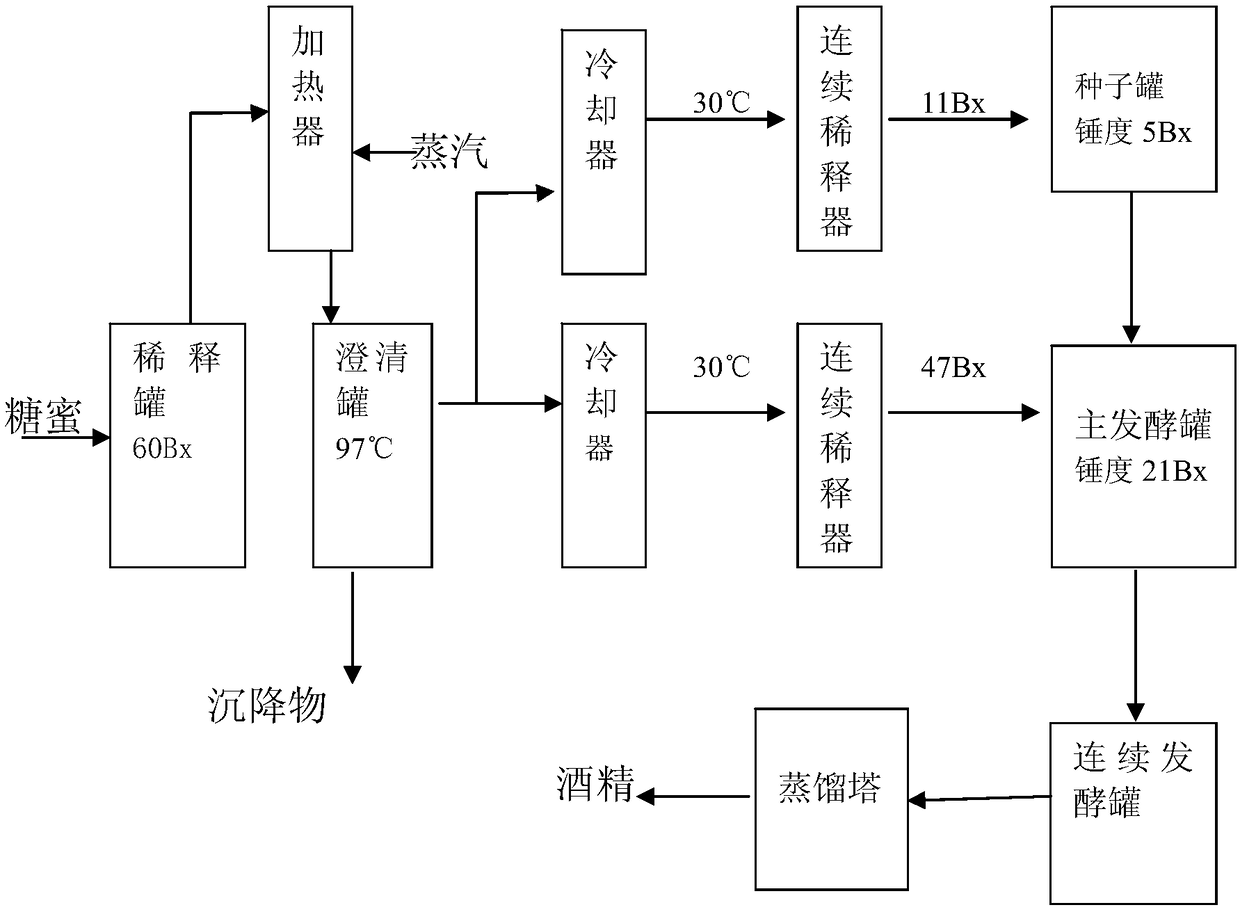

[0021] A kind of method of biological antibacterial molasses alcoholic fermentation of the present embodiment, its process flow chart is as follows figure 1 As shown, the specific steps are as follows:

[0022] (1) In the dilution tank, dilute the molasses to 60Bx, heat the heater to 97°C with steam, flow into the clarification tank, pass through sterile compressed air to stir for 1 hour, let it settle for 1 hour, and remove the sediment at the bottom of the tank.

[0023] (2) Part of the material in step (1) is added with 0.7wt.% of ammonium sulfate, and after the cooler is cooled to 30°C, it is diluted to 11Bx (hereinafter referred to as "dilute sugar solution") through a serial diluter and flows into the seed tank. When the volume of the seed tank reaches 50%, stop feeding, inoculate the seed tank with 0.4wt.% high-activity dry yeast (for molasses fermentation), and continuously feed sterile compressed air to stir and cultivate. When the hammer of the feed liquid in the see...

Embodiment 2

[0026] A kind of method of biological antibacterial molasses alcoholic fermentation of the present embodiment, concrete steps are as follows:

[0027] (1) In the dilution tank, dilute the molasses to 65Bx, heat the heater to 100°C with steam, flow it into the clarification tank, pass through sterile compressed air to stir for 1 hour, let it settle for 1 hour, and remove the sediment at the bottom of the tank.

[0028] (2) Part of the material in step (1) is added with 0.8wt.% of ammonium sulfate, and after the cooler is cooled to 30°C, it is diluted to 12Bx (hereinafter referred to as "dilute sugar solution") through a serial diluter and flows into the seed tank. When the volume of the seed tank reaches 50%, stop feeding, inoculate the seed tank with 0.5wt.% high-activity dry yeast (for molasses fermentation), and continuously feed sterile compressed air into it to stir and cultivate. When the hammer of the feed liquid in the seed tank decreases correspondingly When it reaches...

Embodiment 3

[0031] A kind of method of biological antibacterial molasses alcoholic fermentation of the present embodiment, concrete steps are as follows:

[0032] (1) In the dilution tank, dilute the molasses to 55Bx, heat the heater to 95°C with steam, flow into the clarification tank, pass through sterile compressed air to stir for 1 hour, let it settle for 1 hour, and remove the sediment at the bottom of the tank.

[0033] (2) Part of the material in step (1) is added with 0.6wt.% of ammonium sulfate, and after the cooler is cooled to 30°C, it is diluted to 10Bx (hereinafter referred to as "dilute sugar solution") through a serial diluter and flows into the seed tank. When the seed tank reaches 50% of the volume, stop feeding, inoculate the seed tank with 0.3wt.% high-activity dry yeast (for molasses fermentation), and continuously feed sterile compressed air to stir and cultivate. When the hammer of the feed liquid in the seed tank decreases correspondingly When it reaches 4Bx, the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com