Colorful foam concrete

A foam concrete and color technology, applied in the field of foam concrete, can solve problems such as color fastness, durability, and color peeling, and achieve the effects of bright colors, stable suspension system, and improved concrete strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with specific examples.

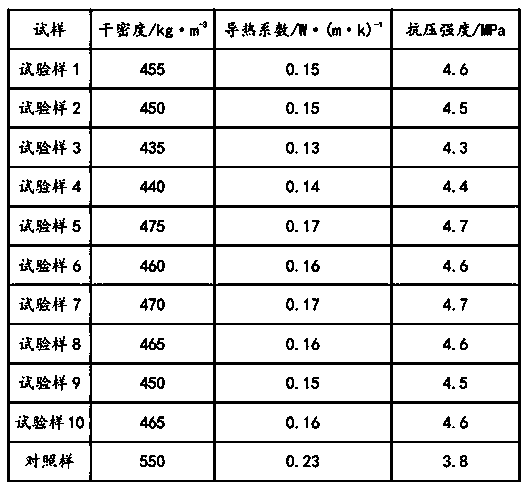

[0028] Embodiments 1-10 all relate to a kind of colored foam concrete, and the mass percentage content of each component in the embodiment is as shown in the table below:

[0029] Table 1. Embodiment 1-10 component mass percent content table

[0030]

[0031] The foaming agents used in Examples 1-10 are animal protein foaming agents, and the foam stabilizers used are sodium lauryl sulfate. The mass percentage content of each component in the admixture used is: amino water reducer 25%, sodium gluconate 8%, sodium sulfate 3%, polyoxyethylene alcohol 22%, hydroxypropyl cellulose 5%, hydroxymethyl Cellulose 4%, balance is water.

[0032] The composition of the pigment compound used in Examples 1-10 is shown in the table below:

[0033] Table 2. The mass percentage content table of each component of the pigment composite used in embodiments 1-10

[0034]

[0035...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com