Operation method of multi-head movable unloading crane-form pipe

An operation method and a mobile technology, applied in special distribution devices, packaging, distribution devices, etc., can solve the problems that the electro-hydraulic control system cannot be fully utilized, have many dynamic sealing points, occupy space, etc., achieve simple structure, improve unloading Oil speed, easy-to-manufacture effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with specific embodiments.

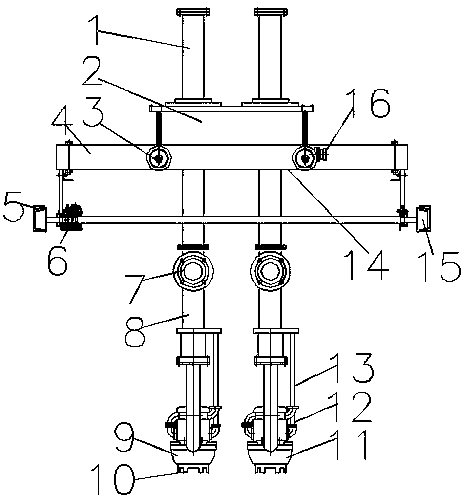

[0018] like figure 1 As shown, a multi-head mobile unloading crane tube includes a hydraulic cylinder 1, a first air motor 16, a second air motor 6, a first mobile trolley 2, a second mobile trolley 4 and an oil unloading device. The first mobile Dolly 2 comprises first wheel 3 and first air motor 16, and described first wheel 3 has four and is fixedly connected by axle shaft in pairs, and wherein a pair of described first wheel 3 is fixed on described first wheel The first air motor 16 on a moving trolley 2 is driven by worm gear transmission, and the first wheel 3 is placed on the first rail 14 provided on the second moving trolley 4; the second moving Dolly 4 comprises second wheel 15 and second air motor 6, and described second wheel 15 has four and is fixedly connected by axle shaft in pairs, and wherein a pair of described second wheel 15 is fixed on described second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com