Centralized liquid supply system of polishing machines

A polishing machine and polishing liquid technology, applied in the field of polishing treatment, can solve the problems of affecting product quality, time-consuming and laborious, polishing powder waste, etc., and achieve the effect of convenient centralized management and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

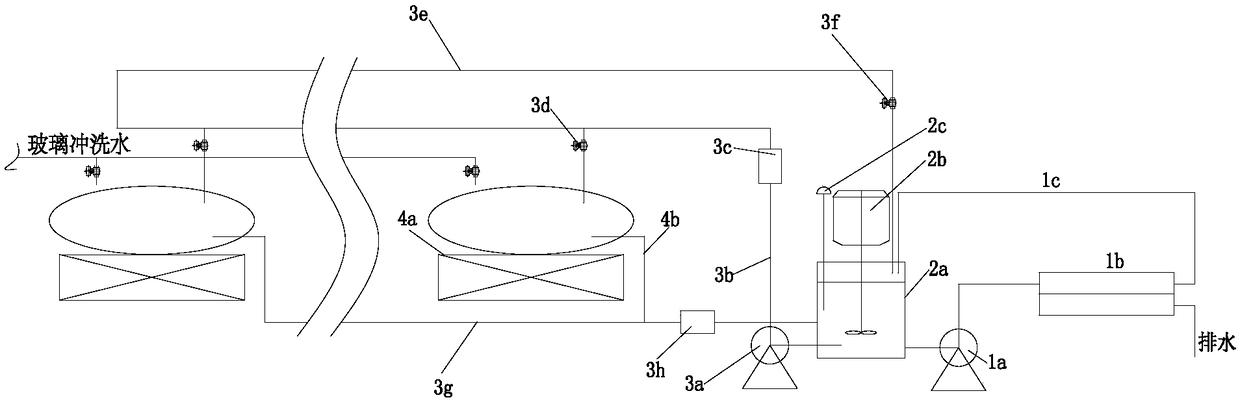

[0019] refer to figure 1 , a centralized liquid supply system for a polishing machine proposed by the present invention includes: a polishing liquid concentration part, a polishing liquid preparation part, and a liquid supply and return pipeline.

[0020] The polishing solution concentration part includes a suction pump 1a, a concentration device 1b and a dope return pipe 1c. The polishing liquid preparation part includes a liquid supply tank 2a and a mixer 2b, and the return line includes a liquid supply pump 3a, a liquid supply pipe 3b and a thin liquid return pipe 3g.

[0021] The stirring blades of the stirrer 2b are inserted into the liquid supply pool 2a, so as to stir the polishing liquid stored in the liquid supply pool 2a, and prevent the polishing powder from settling. The liquid supply pool 2a is provided with a first outlet, a second outlet and a return port. The first outlet communicates with the first end of the liquid supply pipe 3b through the liquid supply p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com