Manufacturing method of shoes with internal height increase

A manufacturing method and shoe technology, applied in the field of shoe manufacturing, can solve problems such as poor shaping effect, easy deformation of shoes, and wear and tear of feet, so as to avoid the generation of moisture and bacteria, reduce the difficulty of secondary processing, and antibacterial long-lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A manufacturing method of inner heightening shoes, the method comprises the following steps:

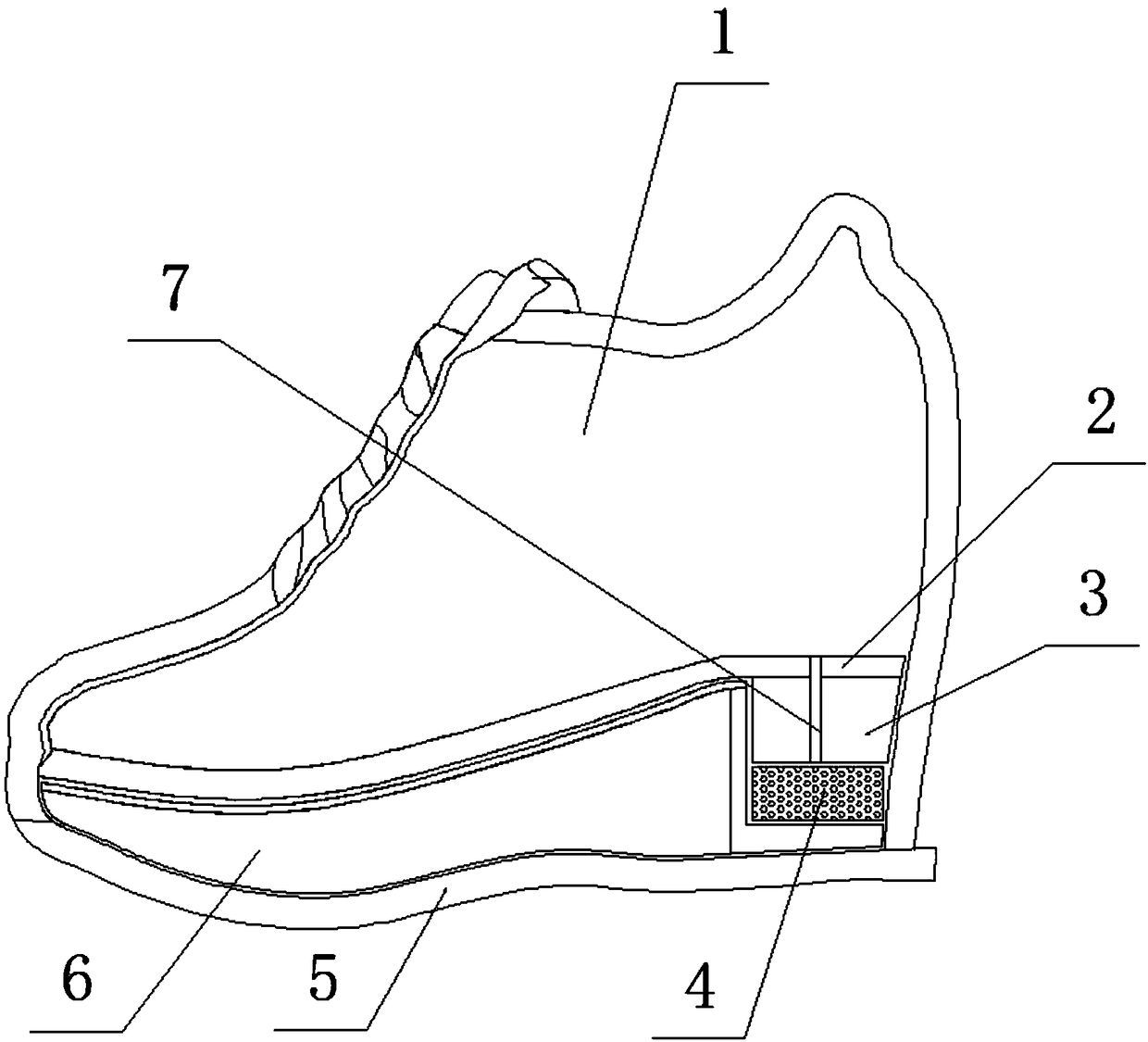

[0025] Step 1, the shoe designer designs the shoe last and the shoe style of the shoe, and selects the materials for making upper 1, sole 5, heightening pad 6, foot pad 2 and matching colors;

[0026] Step 2: Paste the paper on the outside of the shoe last, draw the desired style, and then remove the paper from the shoe last and paste it on the paper to make a paper grid;

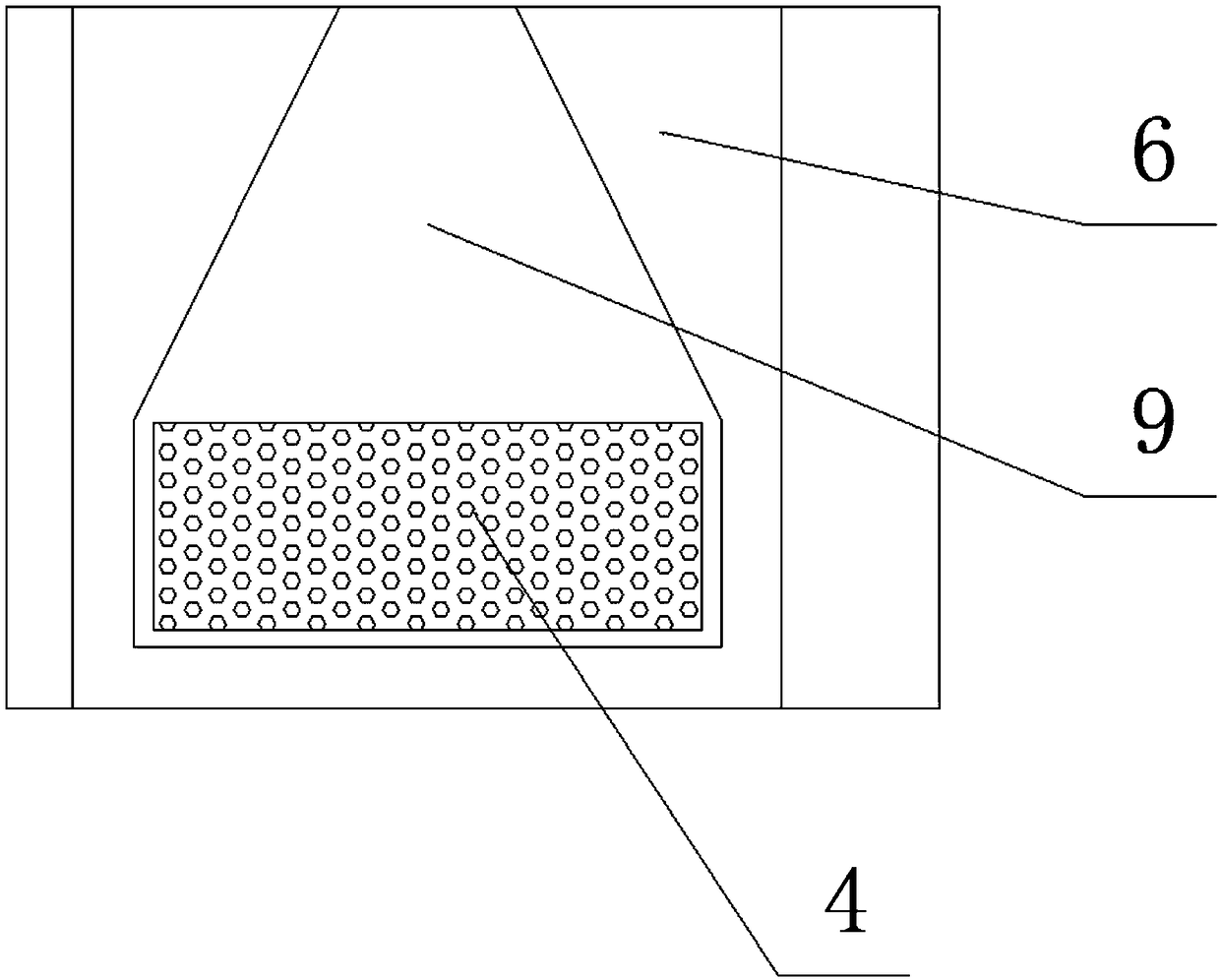

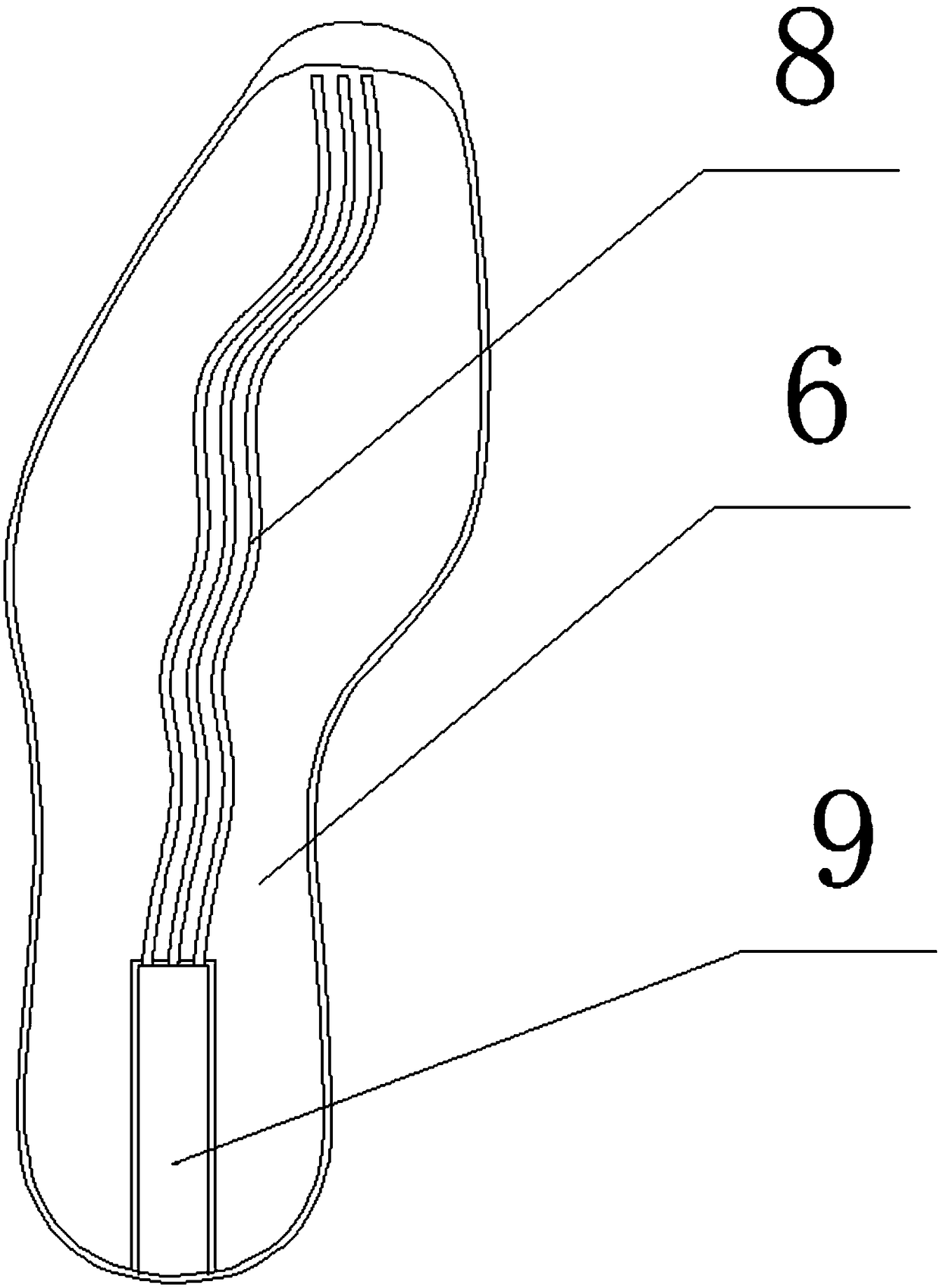

[0027] Step 3: Cut out the upper 1 material selected in step 1 according to the paper grid made in step 2. After cutting, use a leather shoveler to shovel the skin, and then use a sewing machine to sew and splicing the shoveled material. The shoe upper 1 is made, and the material of the sole 5 selected in the step 1 is cut according to the paper grid made in the step 2, and the sole 5 is made. Cut, open a trapezoidal groove 9 where the material thickness of the heightening pad 6 is thick, place a sponge 4 ...

Embodiment 2

[0037] A manufacturing method of inner heightening shoes, the method comprises the following steps:

[0038] Step 1, the shoe designer designs the shoe last and the shoe style of the shoe, and selects the materials for making upper 1, sole 5, heightening pad 6, foot pad 2 and matching colors;

[0039] Step 2: Paste the paper on the outside of the shoe last, draw the desired style, and then remove the paper from the shoe last and paste it on the paper to make a paper grid;

[0040]Step 3: Cut out the upper 1 material selected in step 1 according to the paper grid made in step 2. After cutting, use a leather shoveler to shovel the skin, and then use a sewing machine to sew and splicing the shoveled material. The shoe upper 1 is made, and the material of the sole 5 selected in the step 1 is cut according to the paper grid made in the step 2, and the sole 5 is made. Cut, open a trapezoidal groove 9 where the material thickness of the heightening pad 6 is thick, place a sponge 4 i...

Embodiment 3

[0050] A manufacturing method of inner heightening shoes, the method comprises the following steps:

[0051] Step 1, the shoe designer designs the shoe last and the shoe style of the shoe, and selects the materials for making upper 1, sole 5, heightening pad 6, foot pad 2 and matching colors;

[0052] Step 2: Paste the paper on the outside of the shoe last, draw the desired style, and then remove the paper from the shoe last and paste it on the paper to make a paper grid;

[0053] Step 3: Cut out the upper 1 material selected in step 1 according to the paper grid made in step 2. After cutting, use a leather shoveler to shovel the skin, and then use a sewing machine to sew and splicing the shoveled material. The shoe upper 1 is made, and the material of the sole 5 selected in the step 1 is cut according to the paper grid made in the step 2, and the sole 5 is made. Cut, open a trapezoidal groove 9 where the material thickness of the heightening pad 6 is thick, place a sponge 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com