Non-contact type flexible explosion-proof method and non-contact type flexible explosion-proof device design method

A non-contact, explosion-proof device technology, applied in protective equipment, chemical instruments and methods, clothing, etc., can solve problems such as the inability to weaken the shock wave intensity and fragmentation velocity of large-equivalent explosives, wrong detonation of explosives, and secondary fragmentation hazards. , to achieve the effect of flexible disposal methods, high safety, and strong explosion protection capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

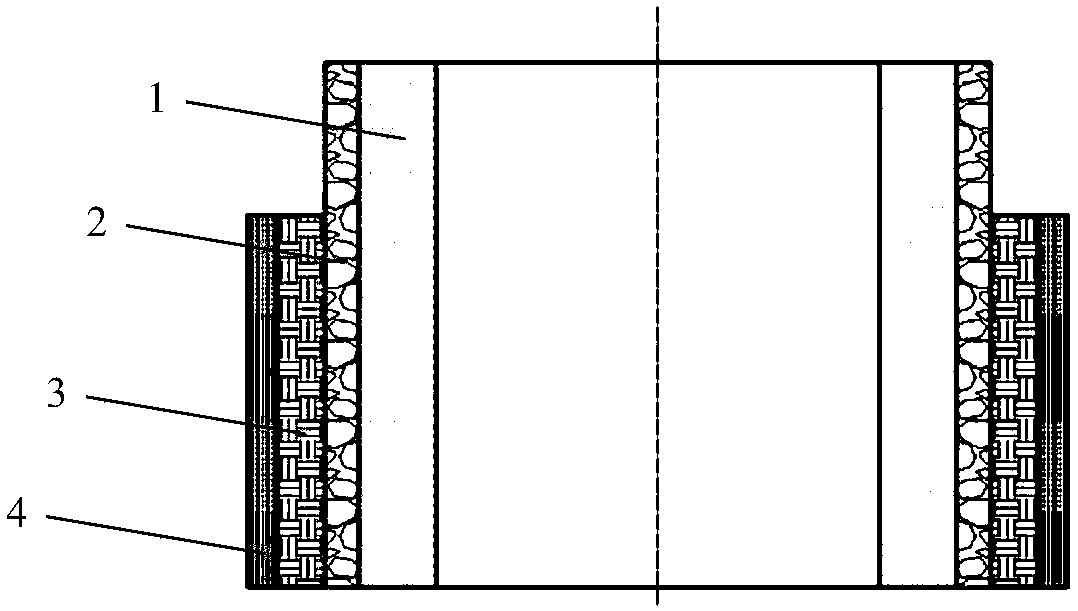

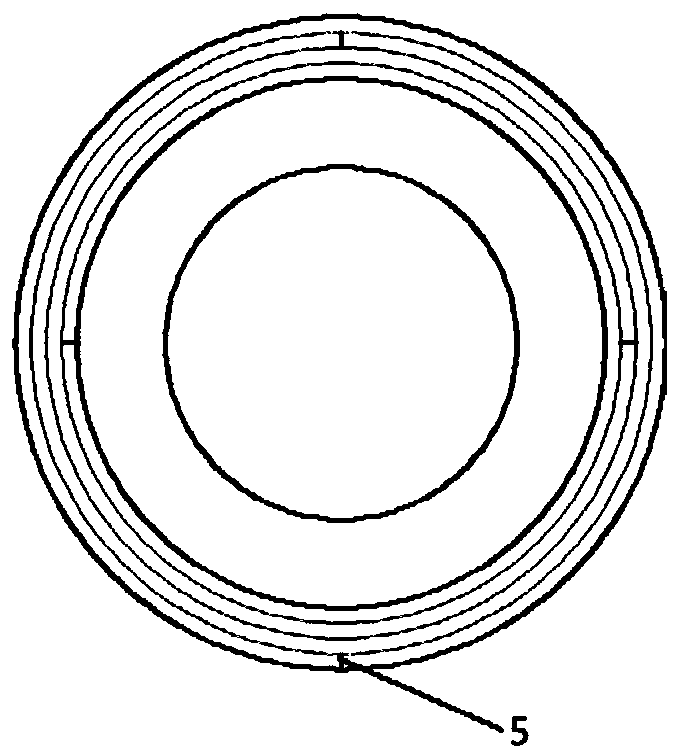

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0026] This embodiment provides a non-contact flexible explosion-proof method and an explosion-proof device design method based on the non-contact flexible explosion-proof method, using flexible materials to efficiently attenuate the velocity of fragments formed by explosives.

[0027] The explosion-proof method is based on the explosion-proof concept of destructible structure, the structural design of multiple flexible materials, the design principles for the temporal and spatial changes of the main load of explosives and the demand for non-contact disposal, the dimensional design process and the oriented The principle of material positioning and connection without the need for secondary additional damage.

[0028] The traditional metal alloy explosion-proof method requires explosion-proof equipment to maintain integrity during the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com