Diesel engine exhaust reforming stratified combustion system and control method

A stratified combustion and diesel engine technology, which is applied in the direction of charging system, exhaust gas recirculation, combustion engine, etc., can solve the problems of incomplete combustion of diesel engine and deterioration of emission, so as to avoid the increase of particulate matter generation, low emission, and suppress combustion The effect of an increase in temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

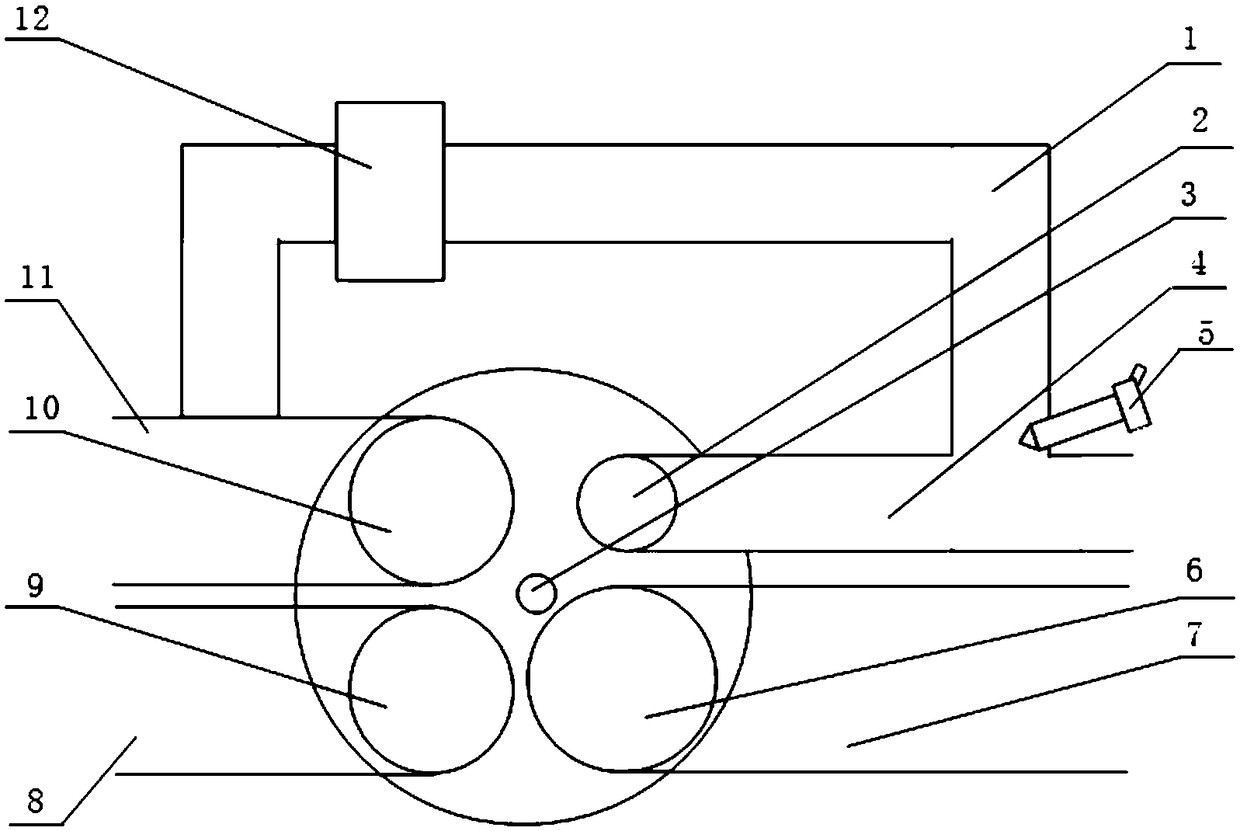

[0021] As shown in the figure, a diesel engine exhaust gas reforming stratified combustion system, including cylinder liner, piston, cylinder head, exhaust gas introduction pipe 1, small exhaust valve 2, fuel injector installation hole 3, small flow exhaust channel 4 alcohol Fuel injector 5, large exhaust valve 6, large flow exhaust port 7, tangential intake port 8, intake valve I9, intake valve II10, spiral intake port 11 and exhaust gas control valve 12; the cylinder head set on the cylinder liner; the piston is set inside the cylinder liner;

[0022] The center of the cylinder head is provided with a fuel injector mounting hole 3; around the fuel injector mounting hole 3, a small exhaust valve 2, a large exhaust valve 6, an intake valve I9 and an intake valve II10 are sequentially arranged clockwise; The intake valve II10 is connected to the spiral intake port 11; the large exhaust valve 6 is connected to a large flow exhaust port 7; the intake valve I9 is connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com