Preparation method of non-ironing finishing agent for chemical fiber fabric

A non-iron finishing and fabric technology, which is applied in fiber treatment, textiles and papermaking, etc., can solve the problems of affecting the wearing comfort of fabrics, the decrease of fabric strength, and poor moisture absorption and air permeability, so as to ensure moisture absorption and air permeability, enhance porosity, and enhance Infiltrating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

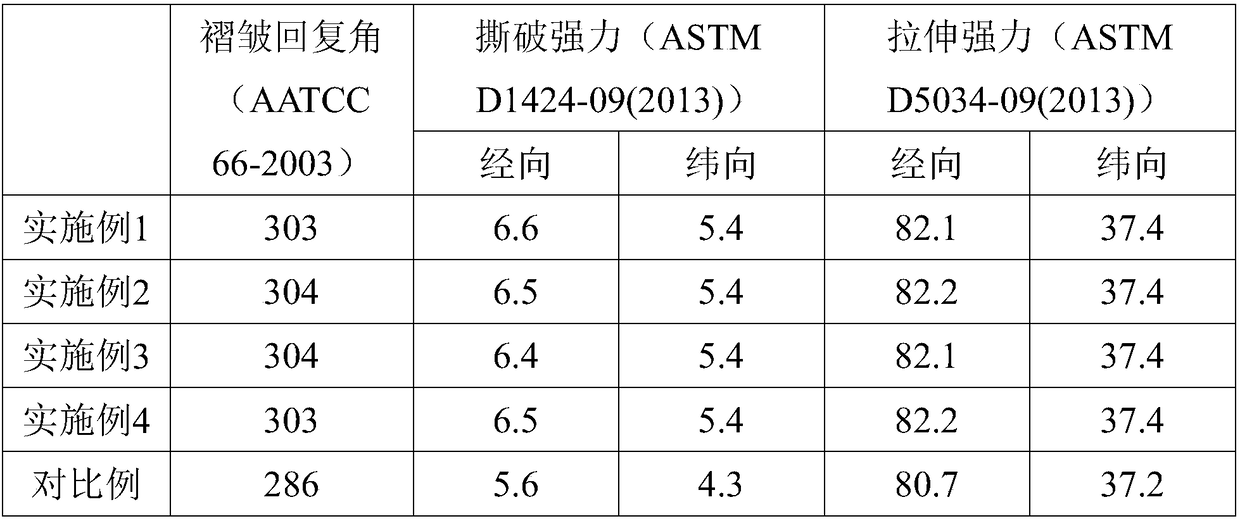

Examples

Embodiment 1

[0028] A preparation method for a non-ironing finishing agent for chemical fiber fabrics, comprising the following steps:

[0029] (1) Put 50 parts of polyester polyurethane into a ball mill and mill it for 80 minutes at a rotating speed of 280r / min. After ball milling, clean it with ethanol and put it into a vacuum drying oven to dry. Among them, zirconia balls are used for ball milling, and the ball-to-material ratio is 1.2:1;

[0030] (2) Mix 100 parts of acrylic acid, 25 parts of bisphenol A epoxy resin, 5 parts of fatty acid diethanolamide and 20 parts of polyparabenamide, put them in a vacuum oven at 90°C for 5 hours, cool and grind, Go through a 120-mesh sieve, put it into an ultrasonic instrument, and ultrasonicate it for 20 minutes under the condition of 60KHz and 150W, wash it with ethanol, put it into a vacuum drying oven to dry, then transfer it to a magnesium chloride solution with a mass concentration of 3%, and ultrasonicate it for 20 minutes under the condition...

Embodiment 2

[0034] A preparation method for a non-ironing finishing agent for chemical fiber fabrics, comprising the following steps:

[0035] (1) Put 60 parts of polyester polyurethane into a ball mill and mill at 240r / min for 90min. After ball milling, wash with ethanol and dry in a vacuum drying oven. Zirconia balls are used for ball milling, and the ball-to-material ratio is 1.3:1;

[0036] (2) Mix 150 parts of acrylic acid, 45 parts of bisphenol-A epoxy resin, 8 parts of fatty acid diethanolamide and 25 parts of polyparabenamide, put them in a vacuum oven at 95°C for 6 hours, cool and grind, Pass through a 120-mesh sieve, put it into an ultrasonic instrument, and ultrasonicate it for 25 minutes under the condition of 60KHz and 150W, wash it with ethanol, put it into a vacuum drying oven to dry, and then transfer it to a magnesium chloride solution with a mass concentration of 4%, and ultrasonicate it for 10 minutes under the condition of 60KHz and 150W. Wash with deionized water and...

Embodiment 3

[0043] A preparation method for a non-ironing finishing agent for chemical fiber fabrics, comprising the following steps:

[0044] (1) Put 70 parts of polyester polyurethane into a ball mill and ball mill for 85 minutes at a speed of 300r / min. After ball milling, use ethanol to clean it, and put it into a vacuum drying oven to dry. Among them, zirconia balls are used for ball milling, and the ball-to-material ratio is 1.2:1;

[0045] (2) Mix 120 parts of acrylic acid, 30 parts of bisphenol A epoxy resin, 6 parts of fatty acid diethanolamide and 22 parts of polyparabenamide, put them in a vacuum drying oven at 100°C for 5 hours, cool and grind, Go through a 120-mesh sieve, put it into an ultrasonic instrument, and ultrasonicate it for 30 minutes under the condition of 60KHz and 150W, wash it with ethanol, put it into a vacuum drying oven to dry, then transfer it to a magnesium chloride solution with a mass concentration of 5%, and ultrasonicate it for 20 minutes under the condi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com