Cotton fabric textile matt producing processing method

A treatment method, cotton fabric technology, applied in the treatment of textile materials, liquid/gas/steam textile material treatment, biochemical fiber treatment, etc., can solve the problem of poor matt color effect, poor production environment, high cost of waste alkali treatment, etc. problem, achieve the effect of improving matte color effect, good effect, and improving cleaning performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

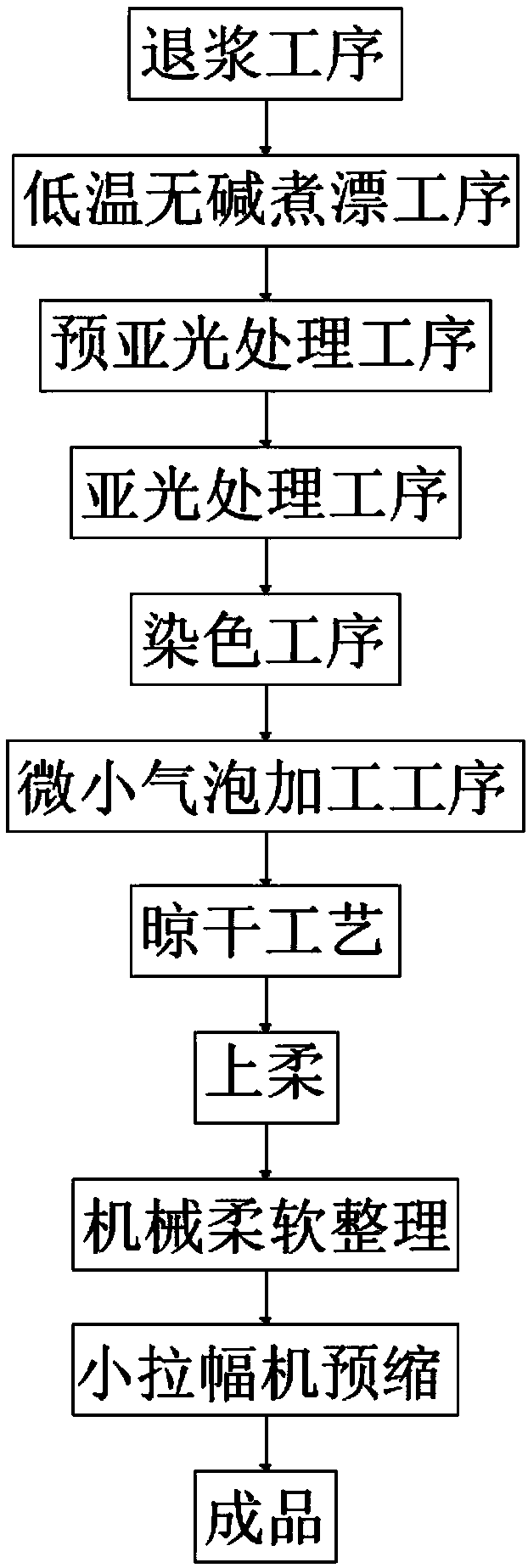

Method used

Image

Examples

Embodiment 1

[0044] A method for producing matt cotton fabric textiles, comprising the following steps:

[0045]Step 1, desizing process, use desizing enzyme to desizing, wash twice after desizing, keep temperature at 60°C during desizing process, desizing enzyme includes PVA degrading enzyme, starch desizing enzyme and soap oil HP6 , the synergistic effect of PVA degrading enzyme, starch desizing enzyme and soap oil HP6 can simultaneously achieve the effect of cleaning starch dye, cleaning PVA size and improving the cleaning performance of the size, which is better than the single type of desizing effect in the prior art Best, add PVA degrading enzyme first, wait for 3h-3h15min, then add starch desizing enzyme and soap oil HP6, wash twice after working together for 45 minutes, the cleaning effect is better when the action of PVA degrading enzyme is close to 4 hours, and desizing enzyme and soap oil HP6 Lime oil HP6 only needs to act for 45 minutes, which is more reasonable for desizing; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com