Gold Extraction Technology of Carbonaceous Refractory Gold Concentrate Microwave Biological Pre-oxidation

A technology for refractory gold and gold concentrates, applied in the direction of improving process efficiency, etc., can solve the problems of limited degradation and ineffective leaching of gold, and achieve the effect of improving the leaching rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

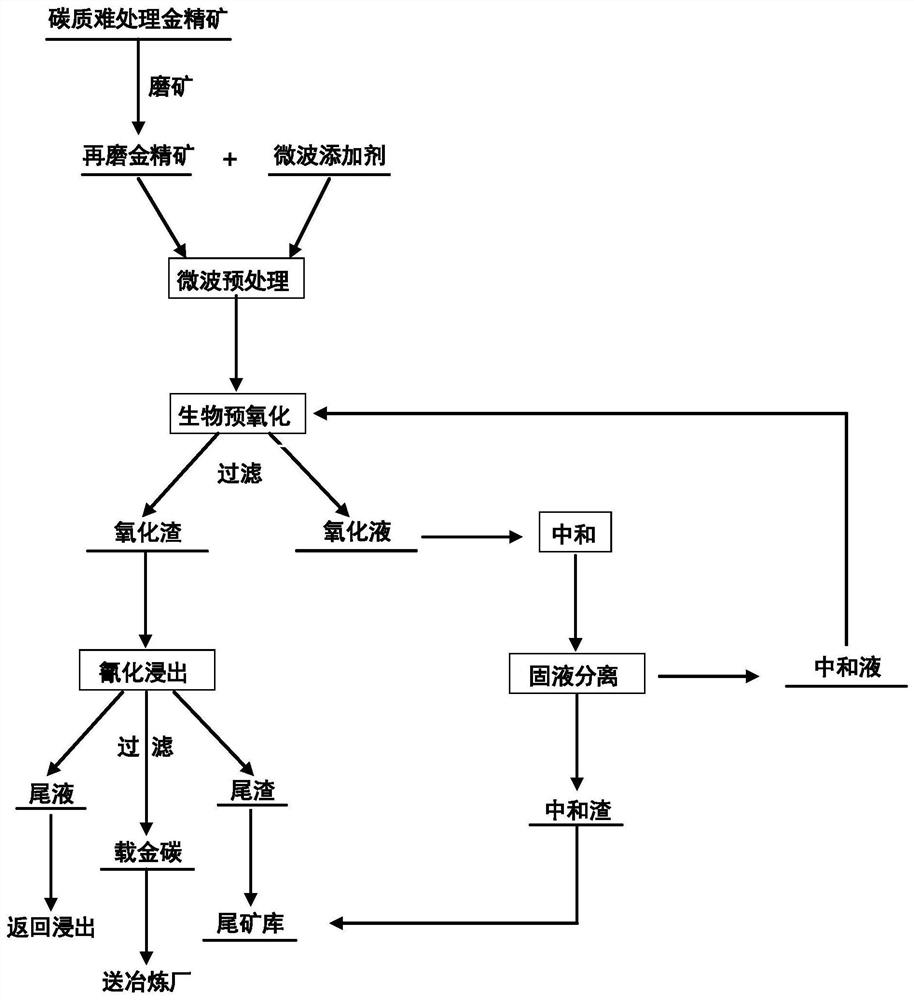

Method used

Image

Examples

Embodiment 1

[0031] A carbonaceous refractory gold concentrate in Guizhou contains Au 16.78g / t, S 35.85%, As 1.47%, total carbon 2.42%, organic carbon 2.08%, gold leaching rate of direct cyanide carbon leaching of gold concentrate is 10.24%, After biological preoxidation, the leaching rate of cyanide carbon leaching gold was 80.18%. This refractory gold concentrate is processed as follows by utilizing the technique of the present invention:

[0032] (1) Gold concentrate grinding

[0033] A carbonaceous refractory gold concentrate in Guizhou was ground to make regrind gold concentrate with a grinding particle size of -0.037mm90%.

[0034] (2) Microwave pretreatment of gold concentrate

[0035] The reground gold concentrate was mixed with 12% CaO, and treated at 1KW, 600°C for 15 minutes, and the degradation rate of organic carbon was 73.25%.

[0036] (3) Biological pre-oxidation of gold concentrate

[0037] After microwave treatment, the gold concentrate was adjusted to a concentration ...

Embodiment 2

[0045]A carbonaceous refractory gold concentrate in Guizhou, containing 28.40g / t of Au, 21.36% of S, 1.93% of As, 3.18% of total carbon, 1.85% of organic carbon, and the direct cyanidation carbon leaching gold leaching rate of gold concentrate is 1.22% , the leaching rate of cyanide carbon leaching gold after biological pre-oxidation was 81.09%. This refractory gold concentrate is processed as follows by utilizing the technique of the present invention:

[0046] (1) Gold concentrate grinding

[0047] Grind a carbonaceous refractory gold concentrate in Guizhou to -0.037mm 95%.

[0048] (2) Microwave pretreatment of gold concentrate

[0049] The carbonaceous refractory gold concentrate after grinding was mixed with 15% NaOH, and treated at 1KW, 600°C for 20min, and the organic carbon degradation rate was 82.15%.

[0050] (3) Biological pre-oxidation of gold concentrate

[0051] After microwave treatment, the gold concentrate was adjusted to a concentration of 15%, and 15% (v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com