Coal pile dustproofing agent

A technology of anti-dust agent and weight percentage, applied in other chemical processes, chemical instruments and methods, etc., can solve problems such as unfavorable use and promotion, reduction of low-level calorific value, waste of water resources, etc., to avoid polluting the environment and coal resources waste, no residue, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

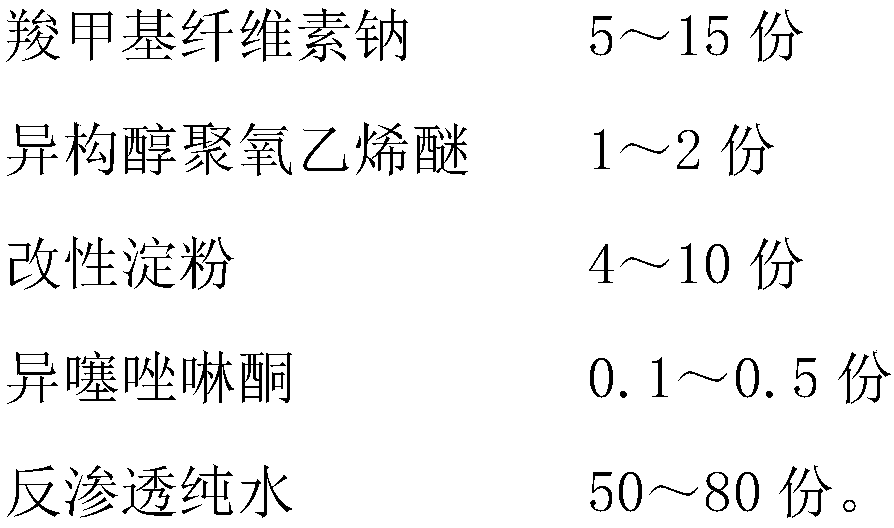

[0021] A kind of coal pile dustproof agent, the weight percent of its each component is formed as:

[0022]

[0023] The coal pile dustproof agent is prepared by the following method: according to 100 parts by weight, 72.5 parts of reverse osmosis pure water, 10 parts of modified starch, 15 parts of sodium carboxymethyl cellulose, 2 parts of isomeric alcohol polyoxyethylene ether, 0.5 part of isothiazolinone, after stirring for 5 minutes, use mobile spraying equipment to evenly spray on the surface of the coal pile according to the amount of 100 grams per square meter of stock solution.

[0024] According to on-site testing, under the condition of wind speed of 15 meters per second, the concentration of coal ash dust is reduced to less than 0.3 mg per cubic meter.

Embodiment 2

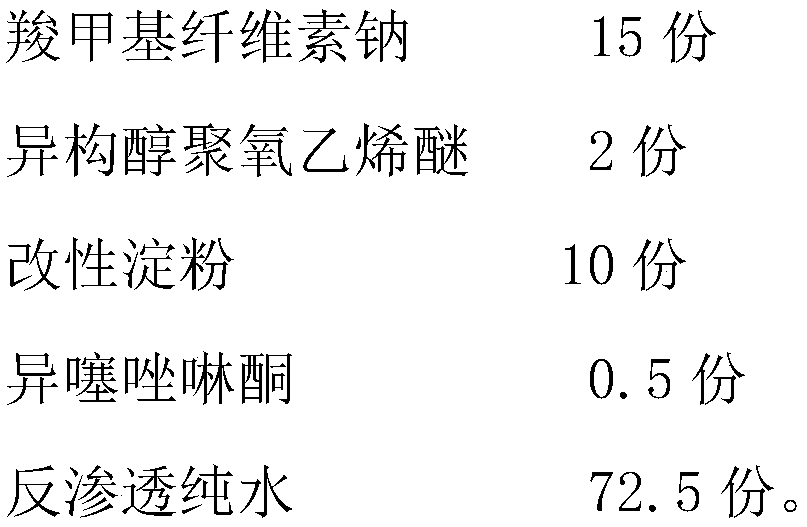

[0026] A kind of coal pile dustproof agent, the weight percent of its each component is formed as:

[0027]

[0028] The coal pile dustproof agent is prepared by the following method: 100 parts by weight, 89.9 parts of reverse osmosis pure water, 4 parts of modified starch, 5 parts of sodium carboxymethylcellulose, 1 part of isomeric alcohol polyoxyethylene ether, 0.1 part of isothiazolinone, after stirring for 3 minutes, use mobile spraying equipment to evenly spray on the surface of the coal pile according to the amount of 160 grams per square meter of stock solution.

[0029] According to on-site testing, under the condition of wind speed of 15 meters per second, the concentration of coal ash dust is reduced to less than 0.3 mg per cubic meter.

Embodiment 3

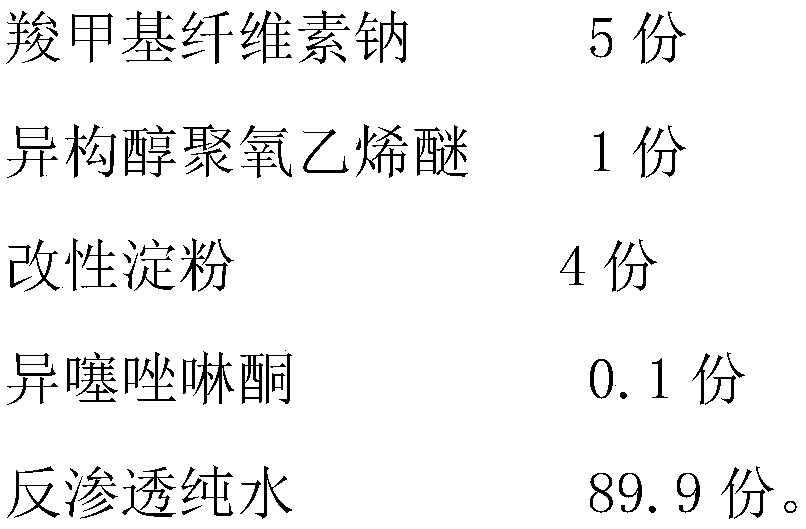

[0031] A kind of coal pile dustproof agent, the weight percent of its each component is formed as:

[0032]

[0033] The coal-heap dustproof agent is prepared by the following method: according to 100 parts by weight, 77.2 parts of reverse osmosis pure water, 8 parts of modified starch, 13 parts of sodium carboxymethylcellulose, 1.5 parts of isomeric alcohol polyoxyethylene ether, 0.3 parts of isothiazolinone, after stirring for 4 minutes, use mobile spraying equipment to evenly spray on the surface of the coal pile according to the amount of 130 grams per square meter of stock solution.

[0034] According to on-site testing, under the condition of wind speed of 15 meters per second, the concentration of coal ash dust is reduced to less than 0.3 mg per cubic meter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com