Preparation method of multi-aperture manganese dioxide

A manganese dioxide and multi-aperture technology, applied in the field of electrochemistry, can solve the problems of restricting the free movement of electrons, complicated synthesis steps, and long reaction time, and achieve the effects of increasing electrical conductivity, making the synthesis method simple and convenient, and protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

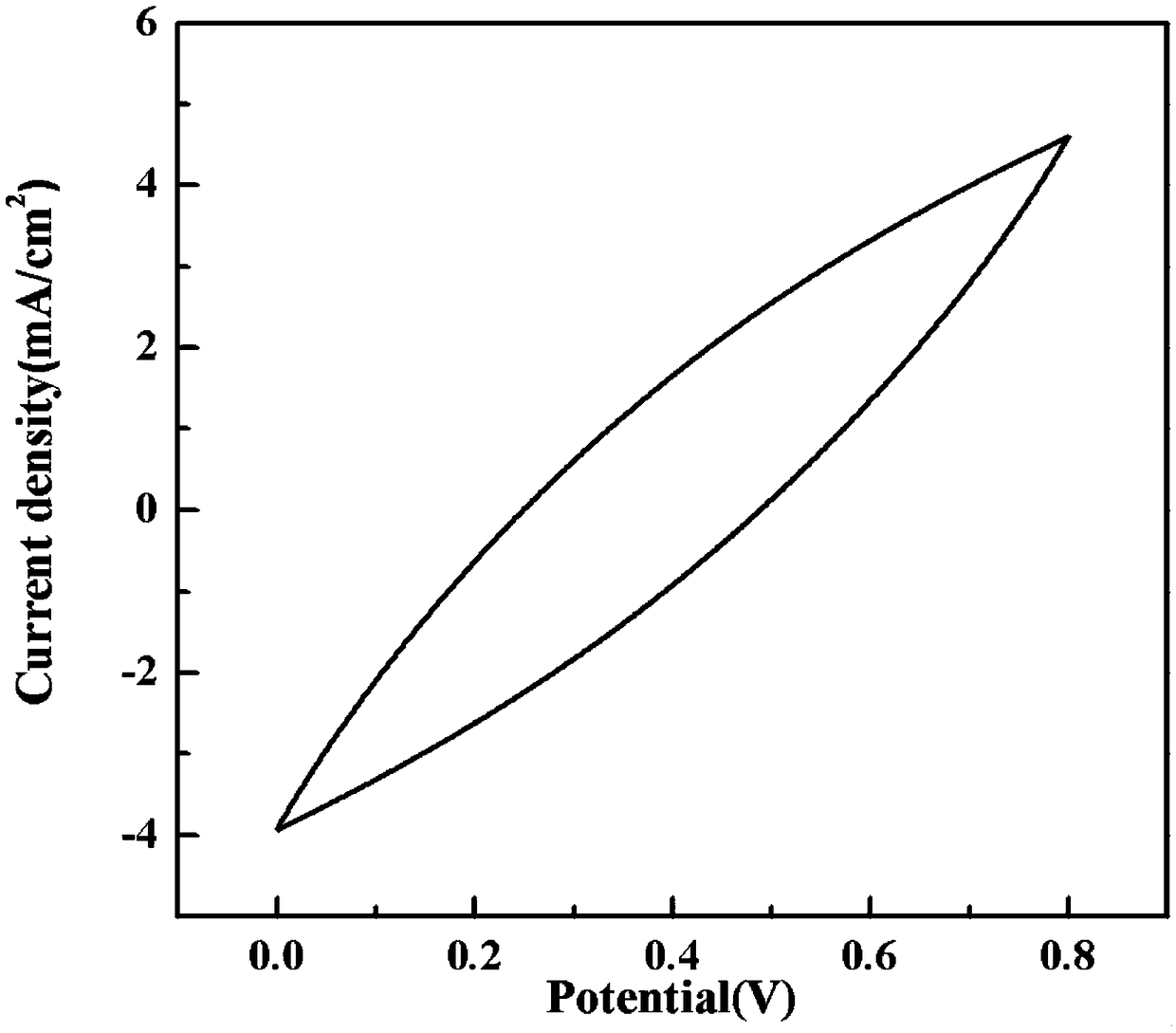

Image

Examples

Embodiment 1

[0030] A preparation method of porous manganese dioxide, comprising the following steps:

[0031] S1), the preparation of manganese acetate gel A, mix 0.10~0.25mol / L manganese acetate solution with rice starch with a particle size of 4 μm, and stir with a magnetic stirrer at 80°C until a uniform sol is obtained to obtain manganese acetate gel Glue A spare;

[0032] S2), the preparation of manganese acetate gel B, the manganese acetate solution of 0.10~0.25mol / L is mixed with the cornstarch that particle diameter is 16 μ m, under the condition of 80 ℃, stir with magnetic stirrer until uniform sol, obtain manganese acetate gel Glue B is spare;

[0033] S3), the preparation of manganese acetate gel C, mix 0.10~0.25mol / L manganese acetate solution with potato starch with a particle size of 50 μm, and stir with a magnetic stirrer at 80°C until a uniform sol is obtained to obtain manganese acetate gel Glue C spare;

[0034] S4), gel-coated graphite sheet, apply the manganese acet...

Embodiment 2

[0038] A preparation method of porous manganese dioxide, comprising the following steps:

[0039] S1), the preparation of manganese acetate gel A, mix 0.10~0.25mol / L manganese acetate solution with rice starch with a particle size of 4 μm, and stir with a magnetic stirrer at 70°C until a uniform sol is obtained to obtain manganese acetate gel Glue A spare;

[0040] S2), the preparation of manganese acetate gel B, the manganese acetate solution of 0.10~0.25mol / L is mixed with the corn starch that particle diameter is 16 μ m, under the condition of 65 ℃, stir with magnetic stirrer to uniform sol, obtain manganese acetate gel Glue B is spare;

[0041] S3), the preparation of manganese acetate gel C, mix 0.10~0.25mol / L manganese acetate solution with potato starch with a particle size of 50 μm, and stir with a magnetic stirrer at 70°C until a uniform sol is obtained to obtain manganese acetate gel Glue C spare;

[0042] S4), gel-coated graphite sheet, apply the manganese acetat...

Embodiment 3

[0045] A preparation method of porous manganese dioxide, comprising the following steps:

[0046] S1), the preparation of manganese acetate gel A, the manganese acetate solution of 0.10~0.25mol / L is mixed with the rice starch that particle size is 4 μ m, under (65~80 ℃) condition, stir with magnetic stirrer until uniform sol, Obtain manganese acetate gel A for subsequent use;

[0047] S2), the preparation of manganese acetate gel B, the manganese acetate solution of 0.10~0.25mol / L is mixed with the cornstarch that particle diameter is 16 μ m, under (65~80 ℃) condition, stir with magnetic stirrer until uniform sol, Obtain manganese acetate gel B for subsequent use;

[0048] S3), the preparation of manganese acetate gel C, the manganese acetate solution of 0.10~0.25mol / L is mixed with the potato starch that particle diameter is 50 μ m, under (65~80 ℃) condition, stir with magnetic stirrer until uniform sol, Obtain manganese acetate gel C for subsequent use;

[0049]S4), gel-c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com