White carbon black and preparation method and application thereof

A kind of white carbon black, reaction kettle technology, applied in the direction of silicon oxide, silicon dioxide, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

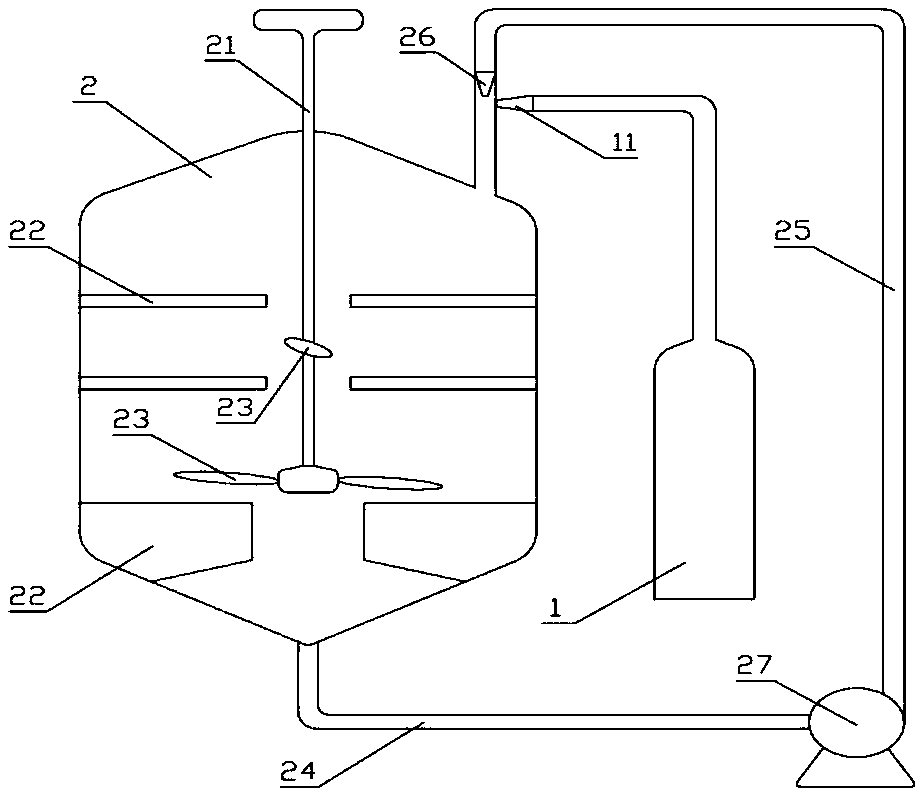

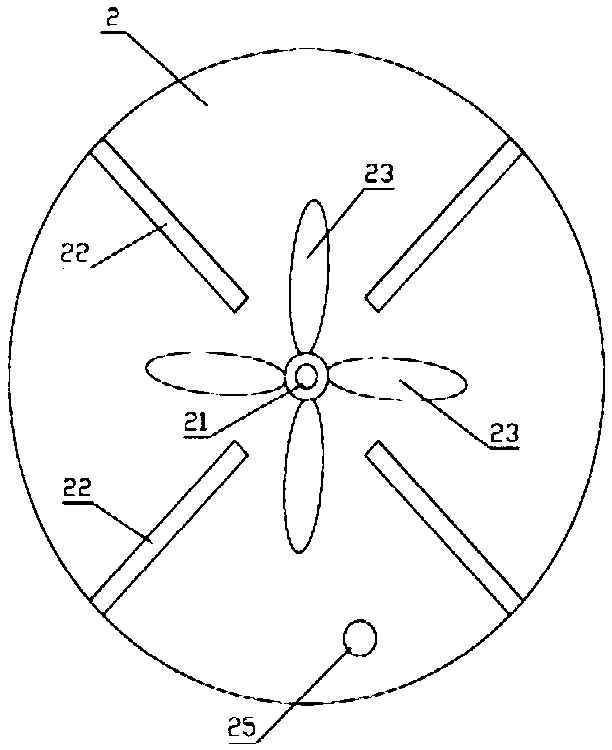

[0162] Such as figure 1 As shown, a generating device for preparing white carbon black includes a reactor 2 and a circulation pump 27, the reactor 2 and the circulation pump 27 are connected by pipelines, and a first circulation pipeline 24 is provided at the bottom of the reactor 2 Connect the inlet of circulation pump 27, the outlet of circulation pump 27 connects the top of reaction kettle 2 by second circulation line 25, in the second circulation line 25, be provided with nozzle 26 near the pipe section of reaction kettle 2, near this nozzle 26 the first The pipe section of the second circulation line 25 is also connected with a vent 11, and the vent 11 communicates with the second circulation line 25, and the vent 11 is connected with the acidifying agent storage device 1 through a pipeline; a stirring device is arranged in the reactor 2;

[0163] The nozzle 26 is preferably set as a cone, the nozzle 26 is arranged as an inverted cone, and the tip of the cone of the nozz...

Embodiment 2

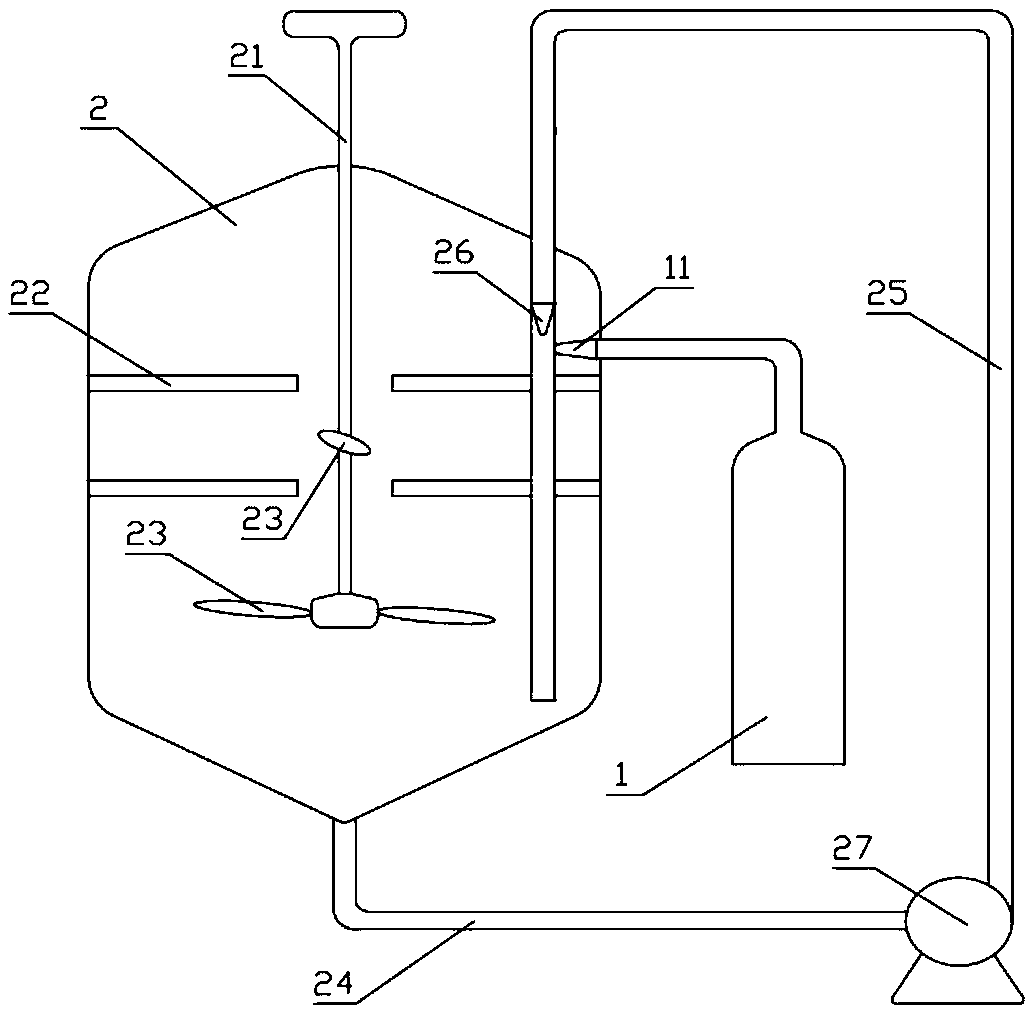

[0179] The difference from Example 1 is that the outlet of the nozzle 26 is located at the top of the reactor 2, and the liquid level of the reactor 2 is up to 2 / 3 of the total volume of the reactor 2, and both the nozzle 26 and the vent 11 are It is required to be located above the liquid level in the reactor 2, therefore, if image 3 As shown, the outlet of the nozzle 26 is located in the top 1 / 3 of the reactor 2; the straight section of the second circulation line 25 extends to the outlet at the bottom of the inner chamber of the reactor 2. The outlet of the second circulation line 25 extends to the bottom of the reactor 2 . Such a structure can ensure that the liquid from the second circulation line 25 flows into the bottom of the reactor 2, and under the action of the stirring device, the liquid containing CO 2 The boiler tail gas fully contacts and reacts with the liquid phase material, and the gas and liquid phase reactants have a larger contact area and a longer resid...

Embodiment 3

[0181] (1) Stir and mix 8,837g of sodium silicate solution and 23,596g of water to obtain a concentration of 0.4mol / L (as Na 2 O meter) sodium silicate solution (modulus M=3.33);

[0182] (2) Place the sodium silicate solution prepared in step (1) in the reaction kettle (Example 1), and heat up to 80°C under stirring; start the pneumatic diaphragm pump, and the sodium silicate solution in the reaction kettle is The suction in the kettle is sprayed below the liquid level of the reaction kettle through the nozzle in the circulation pipeline at a pressure of 0.6MPa to establish the circulation of the sodium silicate solution, wherein the size of the nozzle is 10mm; at the same time, the gas flow is introduced into the reaction kettle through the vent hole It is 18L / min, in which, the air vent is flush with the nozzle nozzle, and the pressure injection makes the carbon black tail gas react with the sodium silicate atomized near the nozzle quickly, and at the same time, the carbon ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com