Injection control system for injection molding machine and control method

A technology of control system and control method, applied in the field of injection control system of injection molding machine, can solve the problems of easy curing of plastics, affecting the quality of injection molded parts, and low accuracy in judging the filling degree of the cavity, so as to increase the thermal conductivity rate and thermal conductivity, The effect of improving injection quality and increasing mixing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

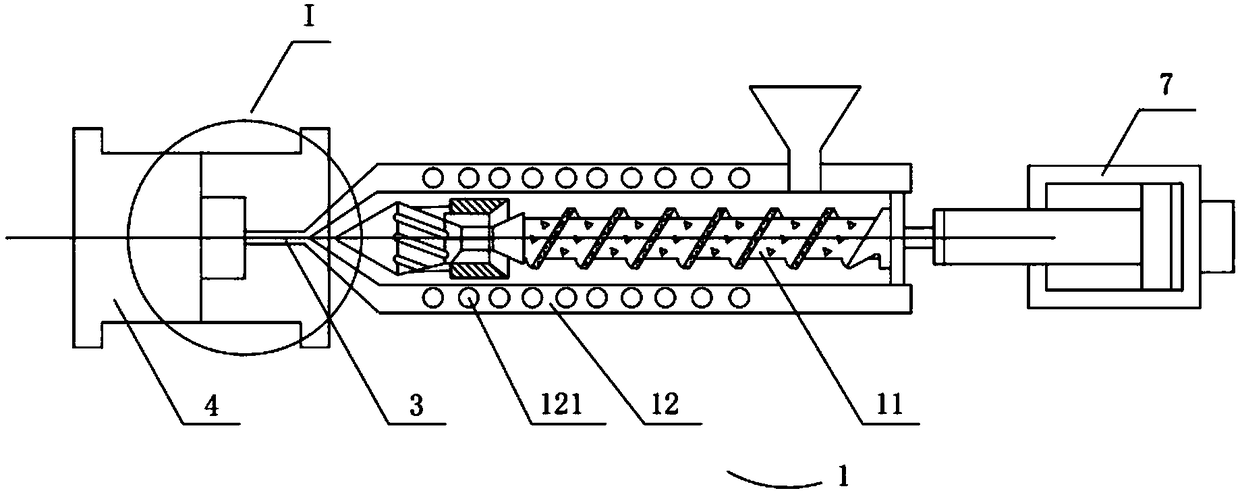

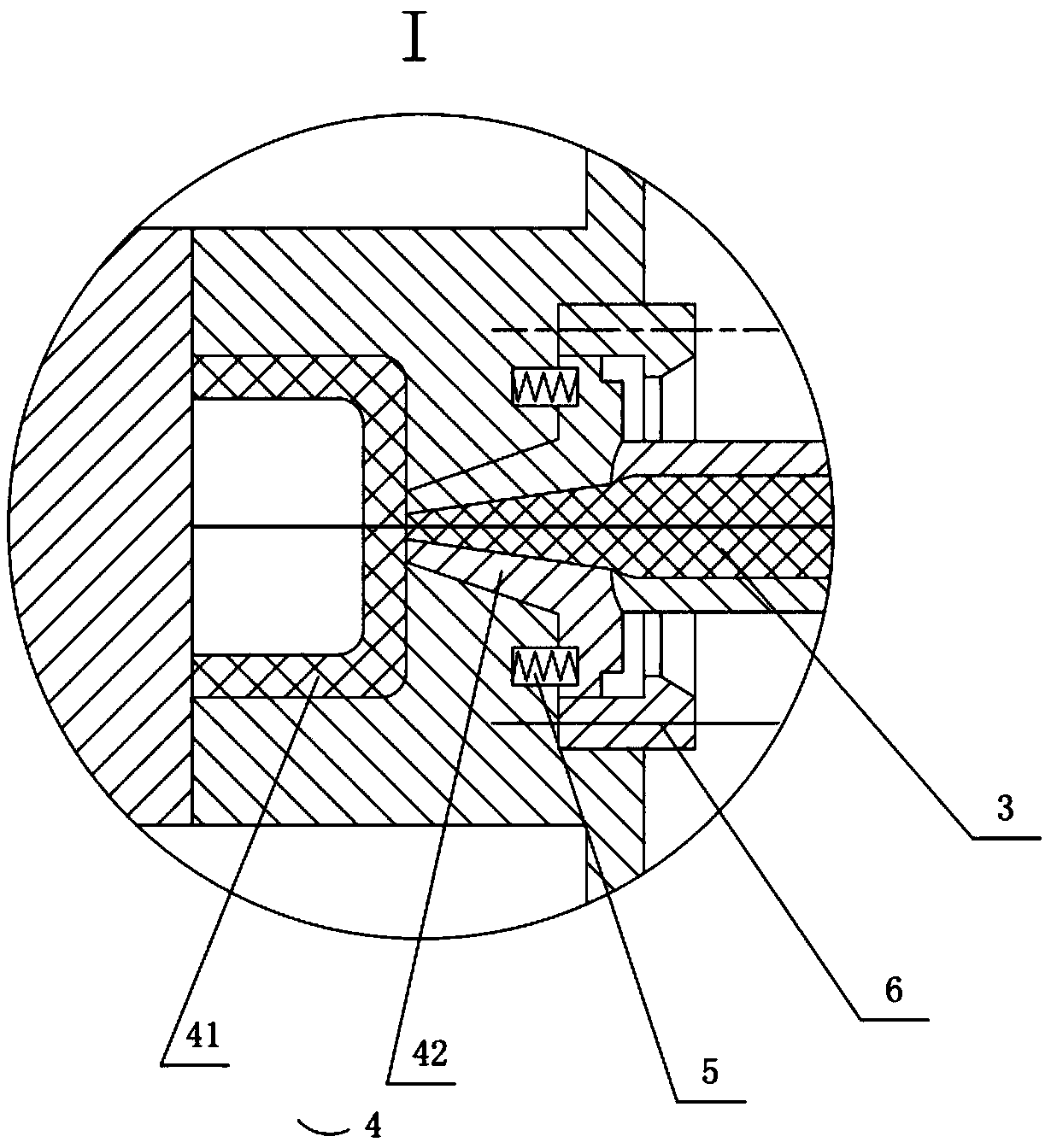

[0039] In order to solve the problems existing in the prior art, the present invention provides an injection control system for an injection molding machine, specifically, refer to figure 1 , figure 2 with image 3 , the injection control system for an injection molding machine includes:

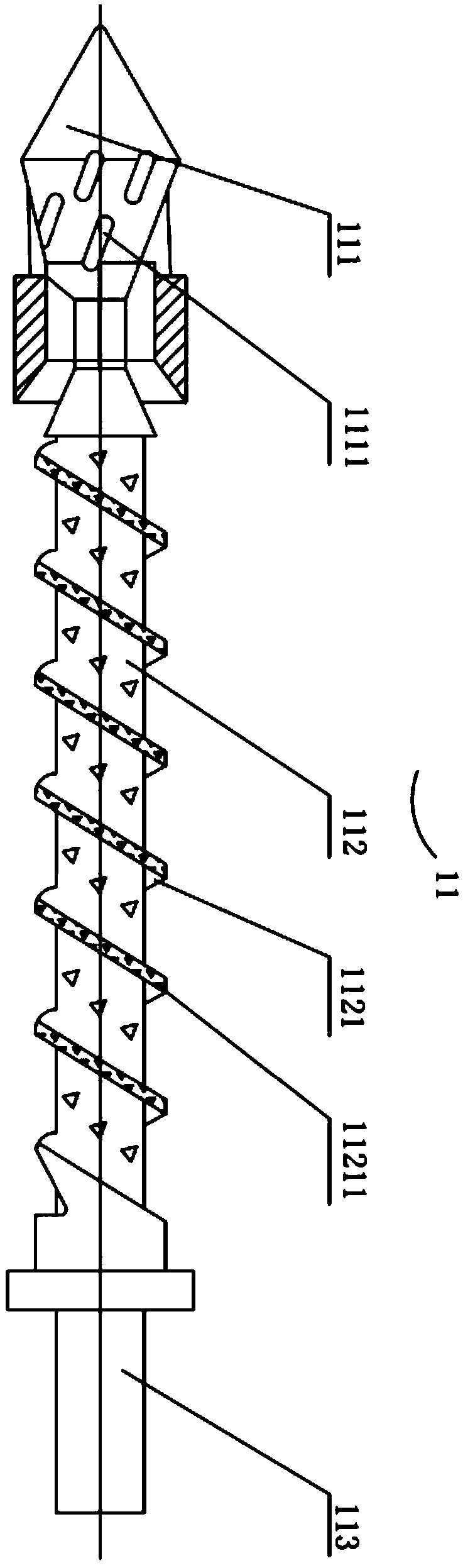

[0040] Plasticizing device 1, screw driving device 7, injection device and nozzle pressure detection device (not shown in the figure), described plasticizing device 1 comprises screw rod 11 and barrel 12, and described screw rod 11 is arranged on described barrel 12 Inside, the barrel 12 is a hollow structure, and a heating coil 121 is arranged in the hollow structure. It can be understood that, by setting the heating coil 121 in the hollow structure of the barrel 12, it can be ensured that the raw material The heat is uniform, and the density of injection molding will not decrease due to the loss of part of the heat during processing.

[0041] The screw driving device 7 provides driving...

Embodiment 2

[0056] This embodiment relates to an injection control method for an injection molding machine. Specifically, refer to Figure 4 , the method includes the steps of:

[0057] S1. Determine whether the current running speed v of the screw 11 is within the range of the preset running speed v', if not, send an alarm; if so, execute step S2,

[0058] S2. The control screw 11 runs at the current running speed v for a preset time T,

[0059] S3. Determine whether the travel distance s of the screw 11 within the preset time T is within the preset travel distance s', if so, execute step S4,

[0060] S4. Determine whether the pressure change Δp of the nozzle 3 within the preset time T is within the range of the preset pressure change Δp', if so, enter the pressure maintaining stage, otherwise send out an alarm.

[0061] Further, the preset operating speed v', the preset travel distance s' of the screw 11 and the preset pressure variation Δp' of the nozzle are preset according to the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com