Oil well cleaning equipment with dirty oil and sewage recovery function

A sewage recovery and cleaning equipment technology, applied in the direction of cleaning equipment, wellbore/well parts, isolation devices, etc., can solve the problems of dirty oil and sewage flowing on the ground, environmental pollution of the well site, etc., to eliminate the sewage flowing to the ground and facilitate use , the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

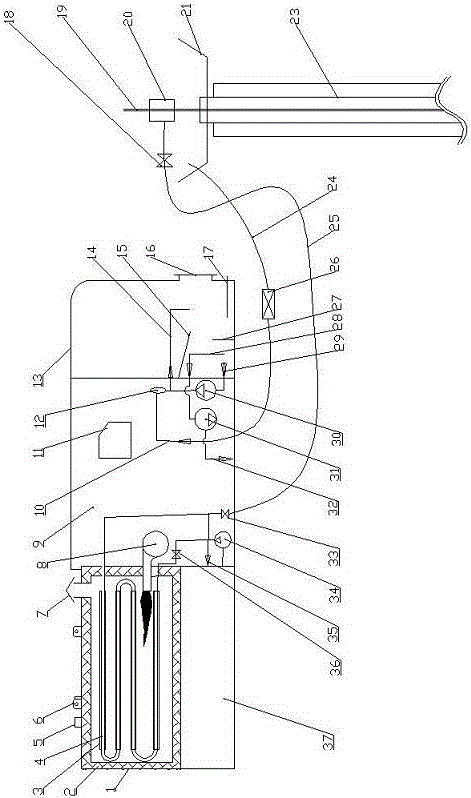

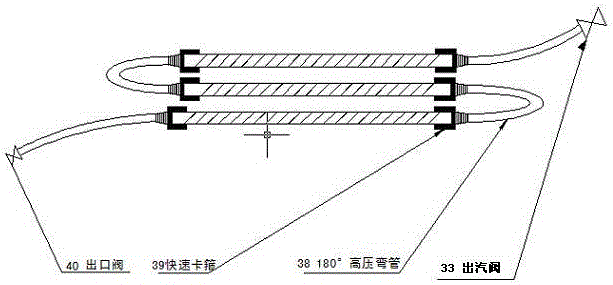

[0009] see figure 1 , the present invention provides a kind of oil well cleaning equipment with the function of recycling dirty oil and sewage, including a steam device, a cleaning device (also called a cleaner) 20 and a sewage recovery device (also called a dirty oil and sewage recovery device), and the steam device includes The heating chamber 1 and the supporting burner 8 for heating the heating chamber, the heating chamber is provided with several horizontal heating sleeves, and the several hundreds of heating sleeves are arranged in layers to form a whole. The inner tube of the heating sleeve is a heating water delivery pipe 4, the outer tube of the heating sleeve is a heating superconductor (abbreviated as a superconductor) 3, and the heating water delivery pipe is connected into a heating water delivery channel through a corresponding elbow A water tank 37 is provided below the heating chamber, and the water inlet valve 36 of the water inlet channel is located at the en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com