High-precision high-hardness low-cost crankshaft machining process

A technology of crankshaft processing and high hardness, which is applied in the field of crankshaft processing, can solve the problems of high operating proficiency requirements for staff, reduced crankshaft fatigue strength, and crankshaft surface damage, etc., to achieve easy use, high hardness and wear resistance, Dust reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

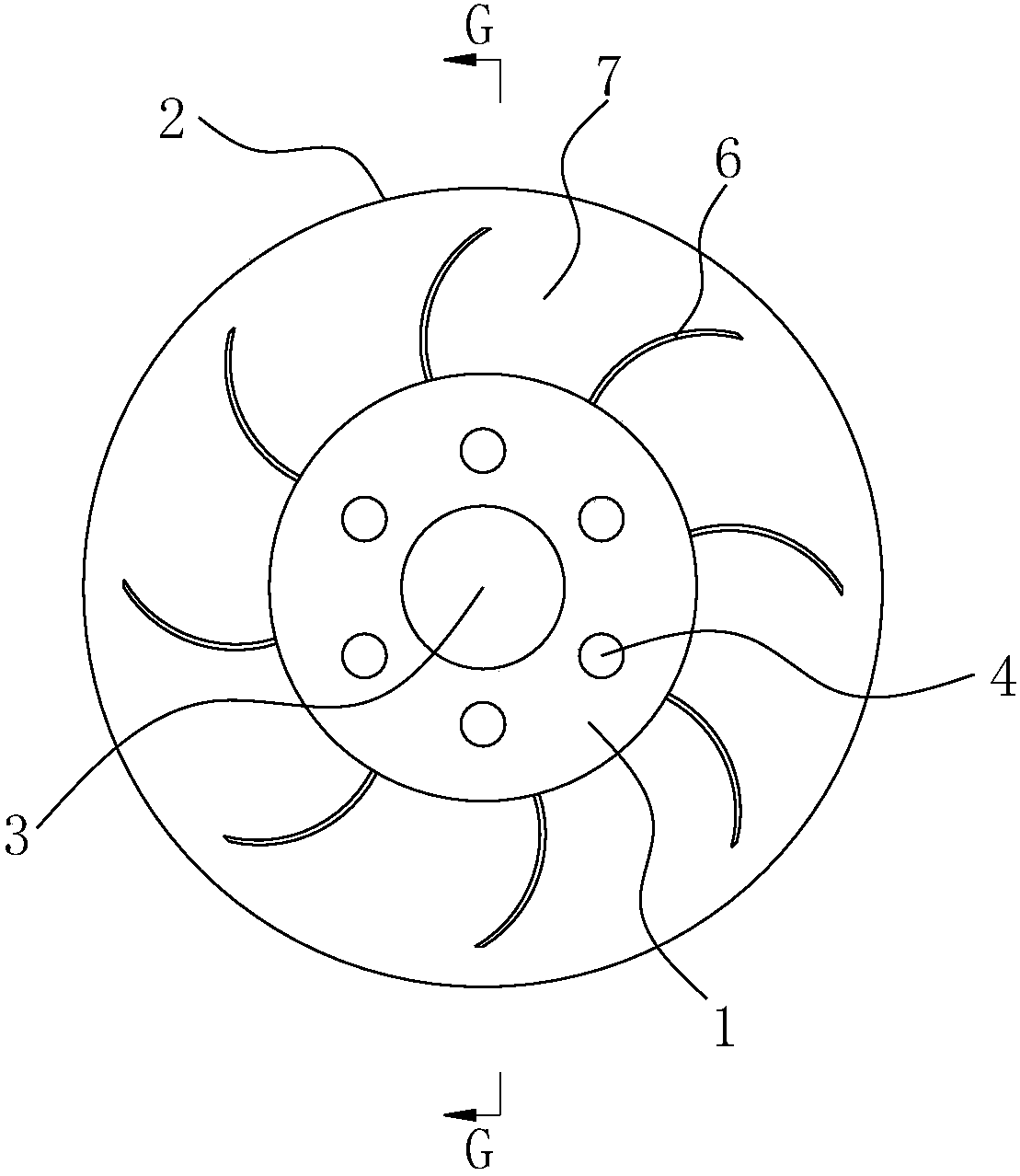

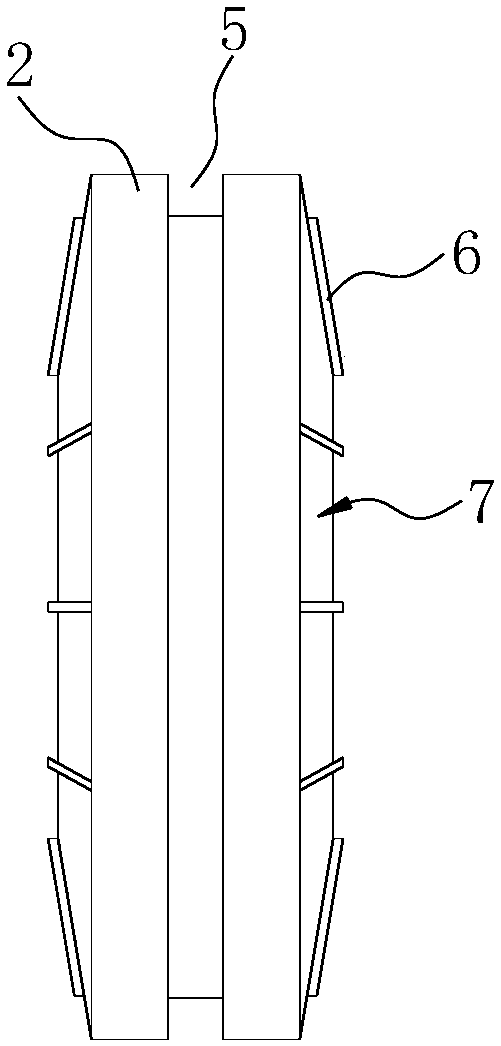

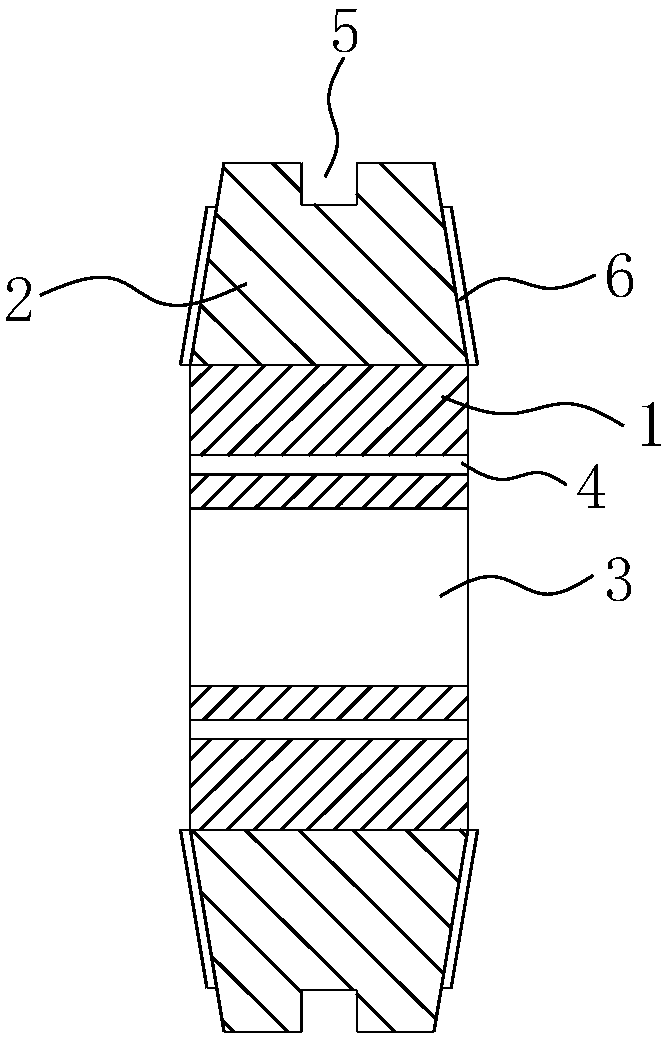

Image

Examples

Embodiment 1

[0035] (1) Forged crankshaft blank;

[0036] (2) Carry out fine and rough turning processing on the crankshaft embryo body;

[0037] (3) Grinding the crankshaft with a grinding wheel;

[0038] (4) Aligning the crankshaft, including the following steps:

[0039] The main journal diameter of the crankshaft is 220mm, and the allowable value of runout is <0.06mm.

[0040] A. Place the two ends of the crankshaft to be straightened on the bracket so that the crankshaft can rotate, and keep the front and rear shafts of the crankshaft horizontal;

[0041] B. While turning the crankshaft, measure the radial runout of each main journal with a dial indicator; record the data, and mark the position with the largest deformation; the results are as follows:

[0042] Main journal number

a

b

c

d

e

f

g

allowance

Runout mm

0.03

0.03

0.02

0.05

0.12

0.23

0.18

<0.06

[0043] Then adjust the position with the largest amount of ...

Embodiment 2

[0064] (1) Forged crankshaft blank;

[0065] (2) Carry out fine and rough turning processing on the crankshaft embryo body;

[0066] (3) Grinding the crankshaft with a grinding wheel;

[0067] (4) Aligning the crankshaft, including the following steps:

[0068] The main journal diameter of the crankshaft is 220mm, and the allowable value of runout is <0.06mm.

[0069] A. Place the two ends of the crankshaft to be straightened on the bracket so that the crankshaft can rotate, and keep the front and rear shafts of the crankshaft horizontal;

[0070] B. While turning the crankshaft, measure the radial runout of each main journal with a dial indicator; record the data, and mark the position with the largest deformation; the results are as follows:

[0071] Main journal number

a

b

c

d

e

f

g

allowance

Runout mm

0.13

0.14

0.13

0.03

0.02

0.01

0.01

<0.06

[0072] Then adjust the position with the largest amount o...

Embodiment 3

[0093] (1) Forged crankshaft blank;

[0094] (2) Carry out fine and rough turning processing on the crankshaft embryo body;

[0095] (3) Grinding the crankshaft with a grinding wheel;

[0096] (4) Aligning the crankshaft, including the following steps:

[0097] The main journal diameter of the crankshaft is 220mm, and the allowable value of runout is <0.06mm.

[0098] A. Place the two ends of the crankshaft to be straightened on the bracket so that the crankshaft can rotate, and keep the front and rear shafts of the crankshaft horizontal;

[0099] B. While turning the crankshaft, measure the radial runout of each main journal with a dial indicator; record the data, and mark the position with the largest deformation; the results are as follows:

[0100] Main journal number

a

b

c

d

e

f

g

allowance

Runout mm

0.14

0.18

0.13

0.03

0.02

0.01

0.01

<0.06

[0101] Then adjust the position with the largest amount o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com