A kind of puffed corn flour with high cellulose content and preparation method thereof

A corn puffed powder, high cellulose technology, applied in food science, food ingredients, applications, etc., can solve problems such as poor expansion, and achieve the effect of improving the hardness value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

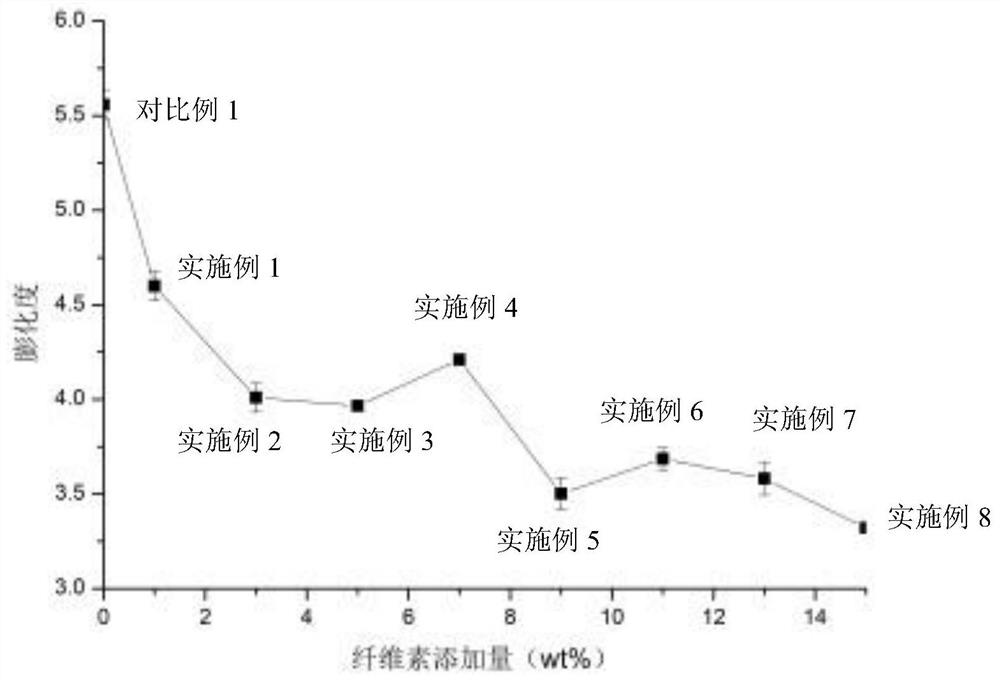

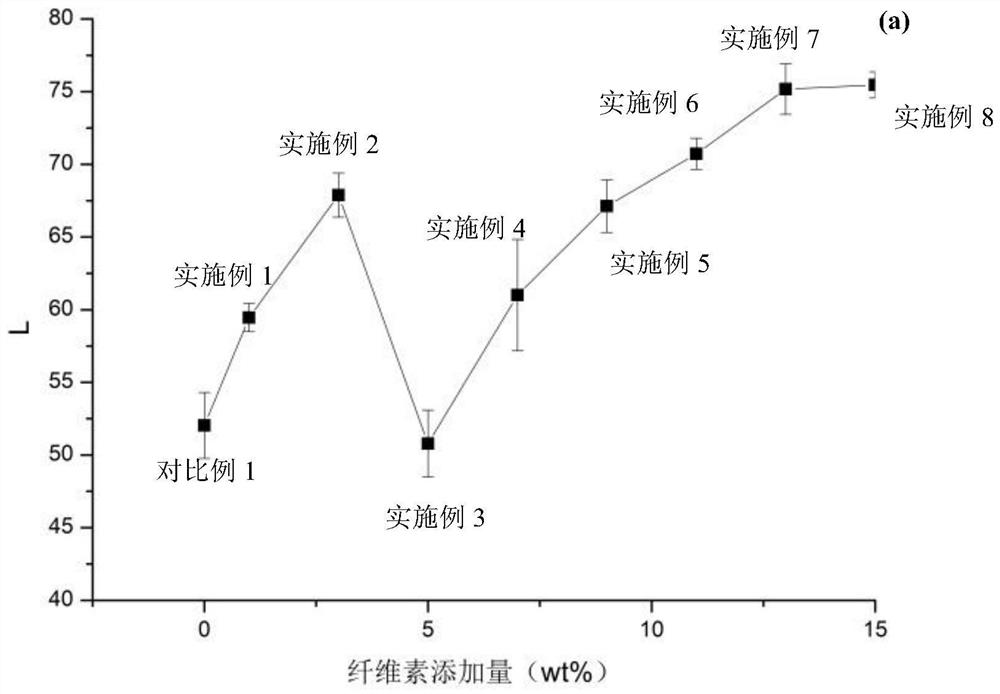

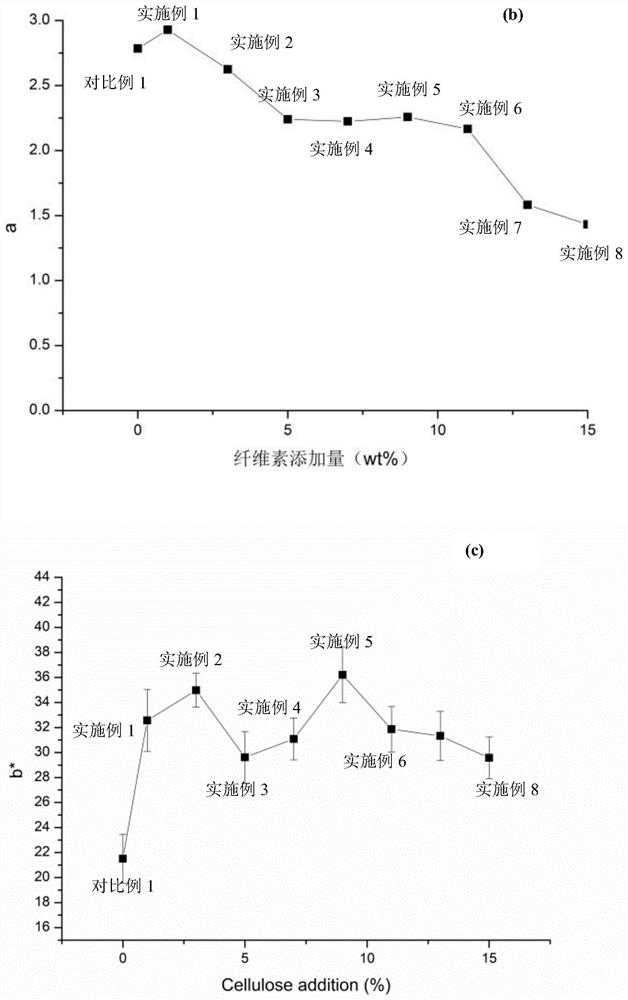

[0053] An extruded corn flour with high cellulose content comprises raw material components and the mass parts of each raw material respectively: 99 parts of corn flour and 1 part of cellulose.

[0054] A preparation method of puffed corn flour with high cellulose content, comprising the following steps:

[0055] Step 1, pretreatment of raw materials

[0056] drying the corn flour at 45°C for more than 24 hours to obtain dried corn flour;

[0057] Step 2, Formulate High Cellulose Corn Slurry

[0058] According to the proportioning ratio, weigh the raw material of corn puffed powder with high cellulose content, add water, and mix evenly to obtain corn slurry with high cellulose content; wherein, the water content of the corn slurry with high cellulose content is 23%;

[0059] Step 3, extrusion puffing

[0060] The mixed slurry is placed in a twin-screw co-rotating extrusion extruder for extrusion and expansion to obtain extruded and expanded corn powder with high cellulose c...

Embodiment 2

[0066] An extruded corn flour with high cellulose content comprises raw material components and the mass parts of each raw material are respectively: 97 parts of corn flour and 3 parts of cellulose.

[0067] A kind of preparation method of puffed corn flour with high cellulose content, same as embodiment 1.

[0068] The puffed corn flour with high cellulose content prepared in this example was tested, and its gelatinization temperature, peak viscosity, retrogradation value, disintegration value, final viscosity and minimum viscosity are shown in Table 1.

[0069] The hardness, weight-average molecular weight (Mw) and molecular weight distribution of the high-cellulose-content puffed corn flour prepared in this example were analyzed, and the results are shown in Table 2.

Embodiment 3

[0071] An extruded corn flour with high cellulose content comprises raw material components and the mass parts of each raw material are respectively: 95 parts of corn flour and 5 parts of cellulose.

[0072] A kind of preparation method of puffed corn flour with high cellulose content, same as embodiment 1.

[0073] The puffed corn flour with high cellulose content prepared in this example was tested, and its gelatinization temperature, peak viscosity, retrogradation value, disintegration value, final viscosity and minimum viscosity are shown in Table 1.

[0074] The hardness, weight-average molecular weight (Mw) and molecular weight distribution of the high-cellulose-content puffed corn flour prepared in this example were analyzed, and the results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com