Beam detection device

A detection device and beam current technology, which is applied in the direction of discharge tubes, electrical components, circuits, etc., can solve the problems of high installation space requirements, difficult wiring, and poor real-time performance, and achieve dense settings, reduce requirements, and improve stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

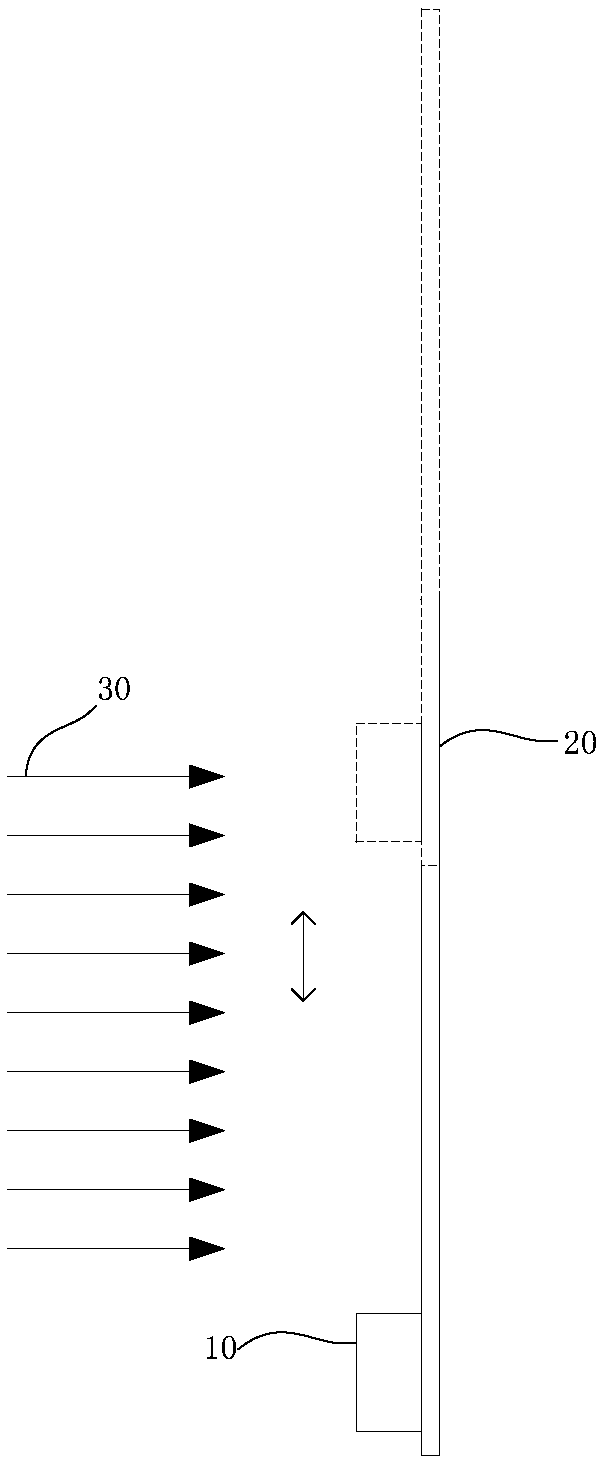

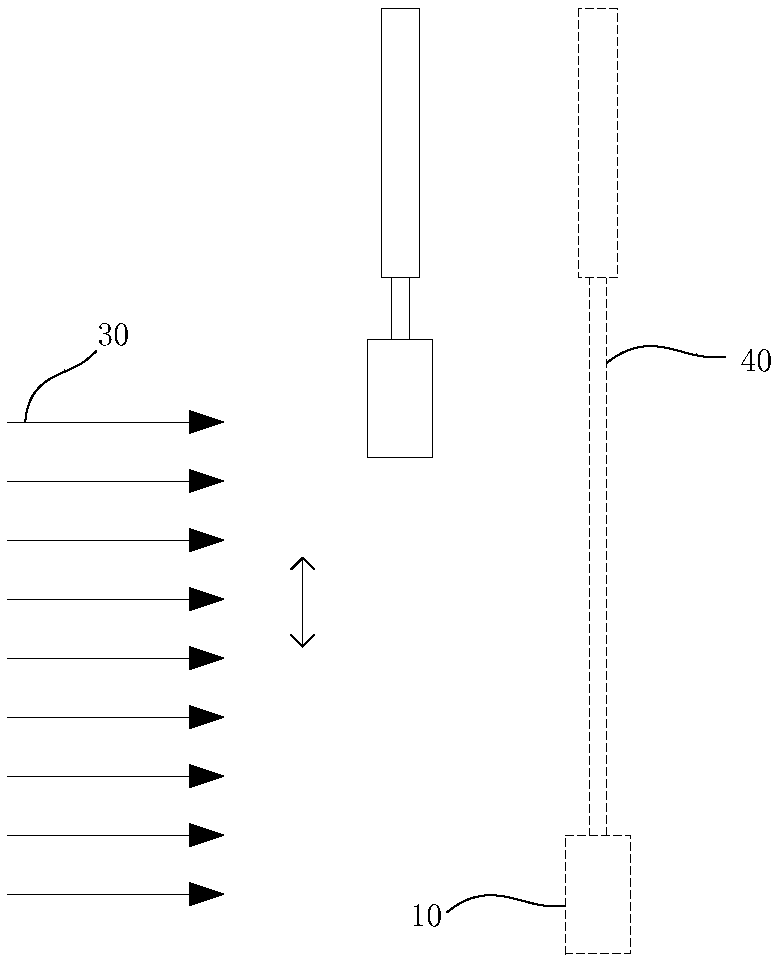

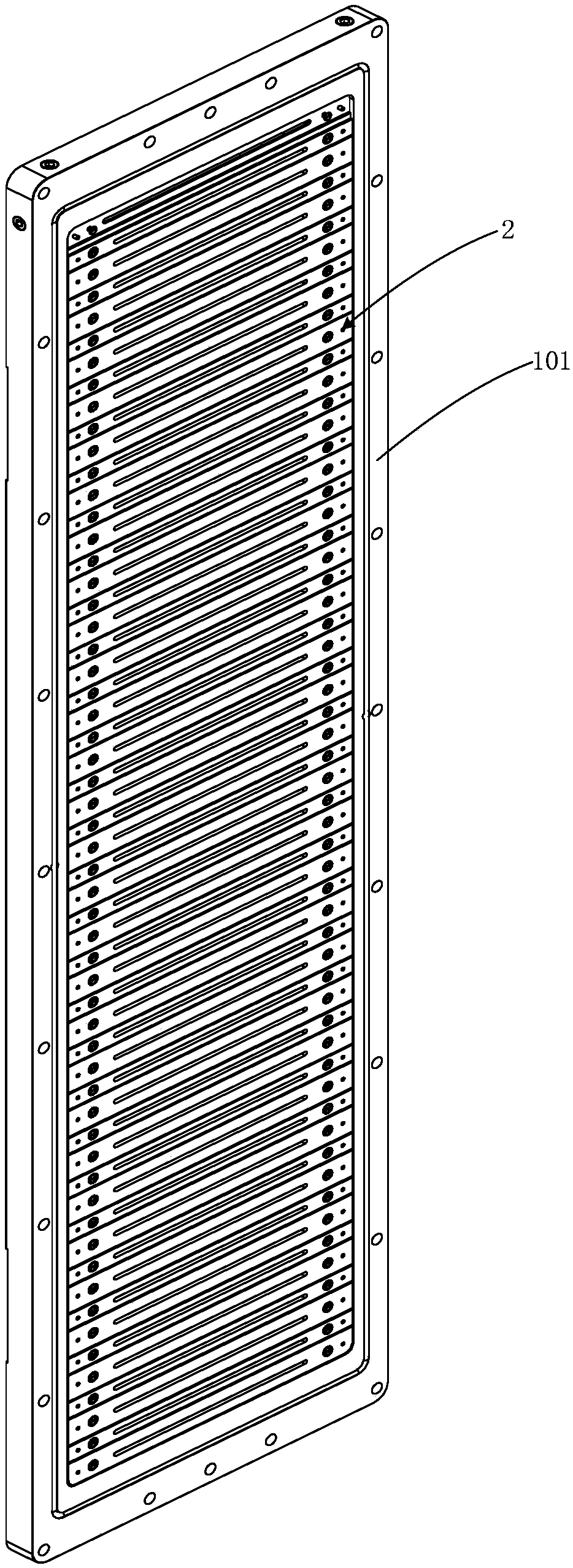

[0049] refer to Figure 3-Figure 13 , introduce the beam detection device described in this embodiment, the beam to be detected is a ribbon beam (ribbon beam), the long side direction of the beam is the y-axis direction, the short side direction of the beam is the x-axis, and the beam The transmission direction of the stream is the z-axis (for the simplicity of the illustration, the coordinate system is only in Figure 7 with Figure 8 Marked in ), the beam detection device is fixed to the cavity wall of a vacuum chamber, the cavity wall includes the atmosphere side 102 located in the atmosphere environment and the vacuum side 101 located in the vacuum environment, the cavity wall is provided with parallel arrays A plurality of first through holes 11, the arrangement direction of the plurality of first through holes 11 is consistent with the long side direction of the beam to be detected, the beam detection device includes: a plurality of Faradays arranged in parallel at inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com