Double-spring balancing cylinder assembly

A technology for a spring assembly and a balance cylinder, which is applied in the field of a double-spring balance cylinder assembly, can solve the problems of increasing the processing difficulty, lengthening the length of the instrument, the length of the piston, etc., and achieves the effect of simplifying the difficulty of maintenance, balancing the internal and external pressure difference, and increasing reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

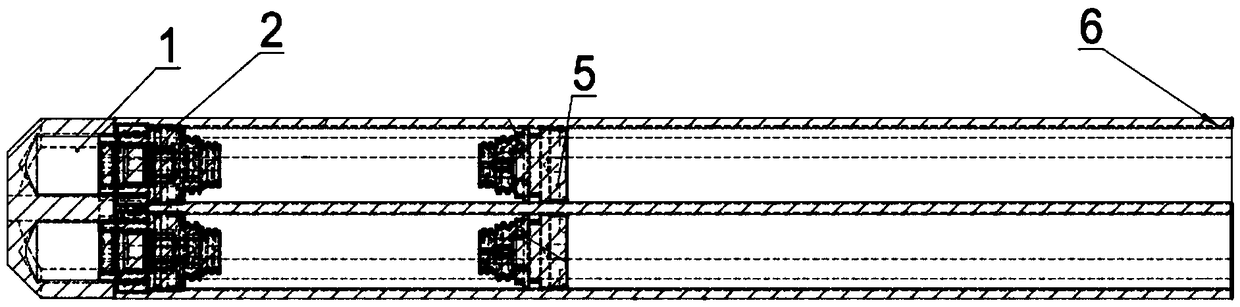

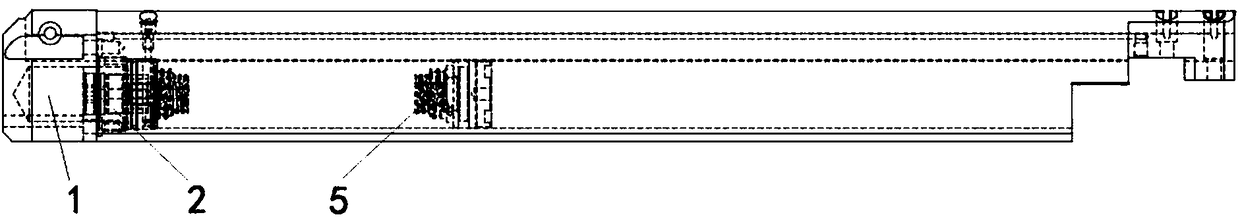

[0037] combine figure 1 , figure 2 As shown, Embodiment 1 of the present invention provides a double-spring balance cylinder assembly, including a cylinder body 6, which is used for parallel installation on the side of the well wall coring cylinder, and at least two pistons are arranged inside the cylinder body 6 cavity; the piston cavity is provided with a sealing base 2, a sealing piston 5 and a spring assembly arranged between the sealing base 2 and the sealing piston 5, and the cavity on the side of the sealing piston 5 away from the spring assembly is a hydraulic oil cavity.

[0038] In the specific operation, the arrangement of multiple piston chambers can effectively shorten the overall length of the cylinder body 6 on the premise of ensuring the reliability of the instrument, can effectively reduce the overall volume of the balance cylinder, and can effectively expand the scope of adaptation of the balance cylinder assembly ;Through the parallel arrangement, the side...

Embodiment 2

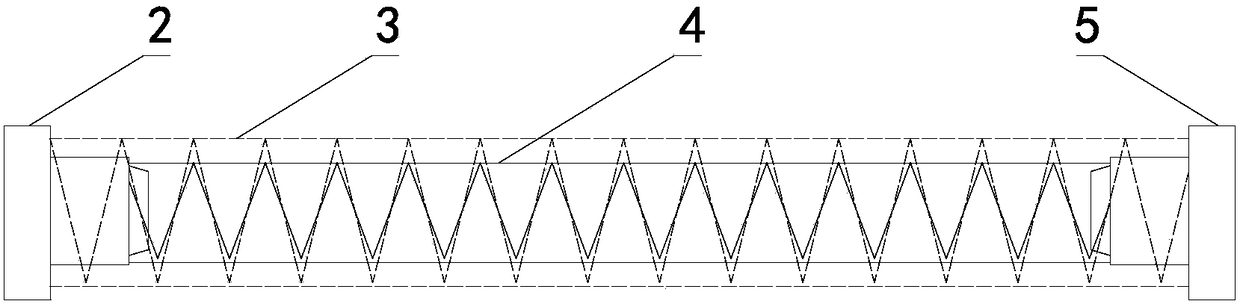

[0053]Embodiment 2 of the present invention provides a double-spring balance cylinder assembly. The main structure is similar to Embodiment 1, and also includes a cylinder body. At least two piston cavities are arranged inside the cylinder body; The piston and the spring assembly arranged between the sealing base and the sealing piston, the cavity on the side of the sealing piston facing away from the spring assembly is a hydraulic oil cavity; for the specific setting of the main structure, please refer to the records in the first embodiment, where the purpose is to explain the difference between the two.

[0054] In this embodiment, the interior of the cylinder is provided with three piston chambers arranged in parallel, and each piston chamber is provided with a sealing base, a sealing piston, and a spring assembly arranged between the sealing base and the sealing piston to form independent The piston cylinder system, and together achieve pressure balance operation.

[0055...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com