Construction method of jacking for super-heavy frame bridge in special geology

A technology with special geology and construction methods, which is applied in the direction of erecting/assembling bridges, bridges, bridge construction, etc., can solve problems such as high construction safety pressure, difficult control of elevation changes, and tight construction schedules, so as to achieve accurate jacking iron positions and improve jacking High precision and good safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

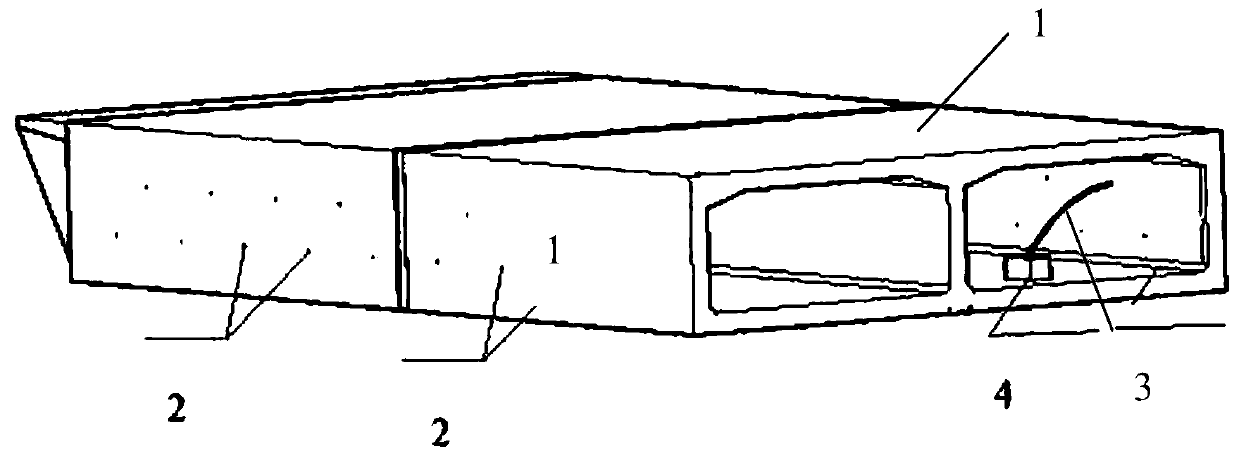

[0021] The jacking construction method of the special geological overweight frame bridge provided by the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0022] An expressway underpasses a railway interchange project. The construction scope involves 5 existing railway lines and 4 reserved lines. The box body constituting the main structure of the frame bridge is a 2-hole structure with a length of 62.666 meters and a width of 36.3 meters. The roof and vertical walls The thickness is 1.1 meters, the bottom plate is 1.2 meters, the net height is 7.2 meters, and the outer height is 9.5 meters. Concrete consumption is 6,860 cubic meters, and the weight of the box is 17,150 tons. Due to the heavy weight of the box body and the tight construction period, if the jacking is used in the relay room, it will not be completed on schedule, which will affect the normal construction of the next step. At the same tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com