A kind of concrete viscosity reducer and preparation method thereof

A technology for viscosity reducing agent and concrete, applied in the field of concrete viscosity reducing agent, can solve the problems of reducing the fluidity of concrete, adverse effects on the later strength of concrete, difficult mass production and application, etc., achieves good compatibility and stability, and improves pump performance. The effect of delivering construction performance and easy mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

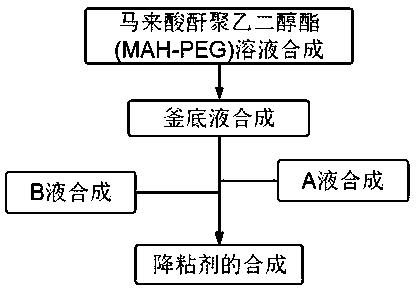

[0027] Embodiment one: a kind of preparation method of concrete viscosity reducer, comprises the following steps:

[0028] S1) Synthesis of maleic anhydride polyethylene glycol ester (MAH-PEG600) solution: Add 500.0 parts of polyethylene glycol (PEG600) into a four-neck flask, heat up to 50°C, start stirring, and put in maleic anhydride (MAH) 86.0 part, then add 0.1 part of hydroquinone and 0.9 part of catalyst in sequence, heat up to 70-80°C, and react for 3-4 hours under constant stirring, the esterification reaction stops, and the yellow or red liquid is polyethylene glycol maleate Ester (MAH-PEG600) solution;

[0029] S2) Synthesis of bottom liquid: 200.0 parts of water, 200.0 parts of maleic anhydride polyethylene glycol ester (MAH-PEG600), and 3.5 parts of chain transfer agent were put into a four-necked flask and stirred and mixed;

[0030] S3) Synthesis of liquid A: Add 50.0 parts of water, 35.0 parts of acrylic acid (AA), 12.0 parts of isooctyl acrylate (2-EAH), and ...

Embodiment 2

[0038] Embodiment two: a kind of preparation method of concrete viscosity reducer, comprises the following steps:

[0039] S1) Synthesis of maleic anhydride polyethylene glycol ester (MAH-PEG800) solution: Add 500.0 parts of polyethylene glycol (PEG800) into a four-necked flask, heat up to 50°C, start stirring, and put in maleic anhydride (MAH) 65.0 Then add 0.07 parts of hydroquinone and 0.7 parts of catalyst in sequence, heat up to 70-80°C, and react for 3-4 hours under constant stirring, the esterification reaction stops, and the yellow or red liquid is polyethylene glycol maleate Ester (MAH-PEG800) solution;

[0040] S2) Synthesis of bottom liquid: 200.0 parts of water, 200.0 parts of maleic anhydride polyethylene glycol ester (MAH-PEG800) and 3.5 parts of chain transfer agent were put into a four-necked flask and stirred;

[0041] S3) Synthesis of liquid A: Add 50.0 parts of water, 35.0 parts of acrylic acid (AA), 12.0 parts of isooctyl acrylate (2-EAH), and 0.2 parts of...

Embodiment 3

[0049] Embodiment three: a kind of preparation method of concrete viscosity reducer, comprises the following steps:

[0050] S1) Synthesis of maleic anhydride polyethylene glycol ester (MAH-PEG1000) solution: Add 500.0 parts of polyethylene glycol (PEG1000) into a four-neck flask, heat up to 50°C, start stirring, and put in maleic anhydride (MAH) 52.0 Then add 0.05 parts of hydroquinone and 0.5 parts of catalyst in sequence, heat up to 70-80°C, and react for 3-4 hours under constant stirring, the esterification reaction stops, and the yellow or red liquid is polyethylene glycol maleate Ester (MAH-PEG1000) solution;

[0051] S2) Synthesis of bottom liquid: put 200.0 parts of water, 200.0 parts of maleic anhydride polyethylene glycol ester (MAH-PEG1000), and 3.5 parts of chain transfer agent into a four-necked flask and stir and mix;

[0052] S3) Synthesis of liquid A: Add 50.0 parts of water, 35.0 parts of acrylic acid (AA), 12.0 parts of isooctyl acrylate (2-EAH), and 0.2 par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com