Method for improving selectivity of citronellol synthesized through citronellal hydrogenation

A technology for citronellol and citronellal, which is applied in the field of improving the selectivity of citronellal hydrogenation to synthesize citronellol, can solve the problems of cumbersome process and low selectivity, and achieves improved selectivity, mild catalytic conditions, high efficiency and high efficiency. high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Preparation of Pt@ZIF-67 catalyst

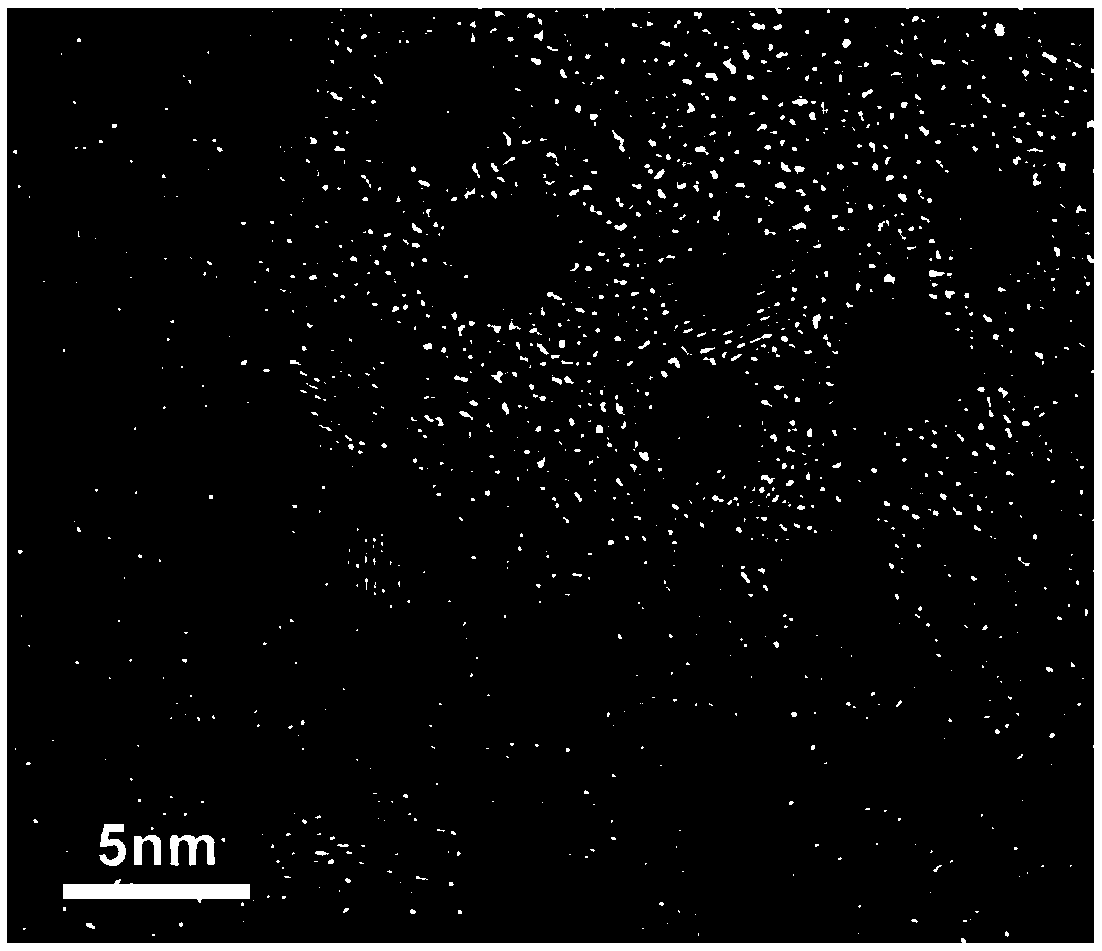

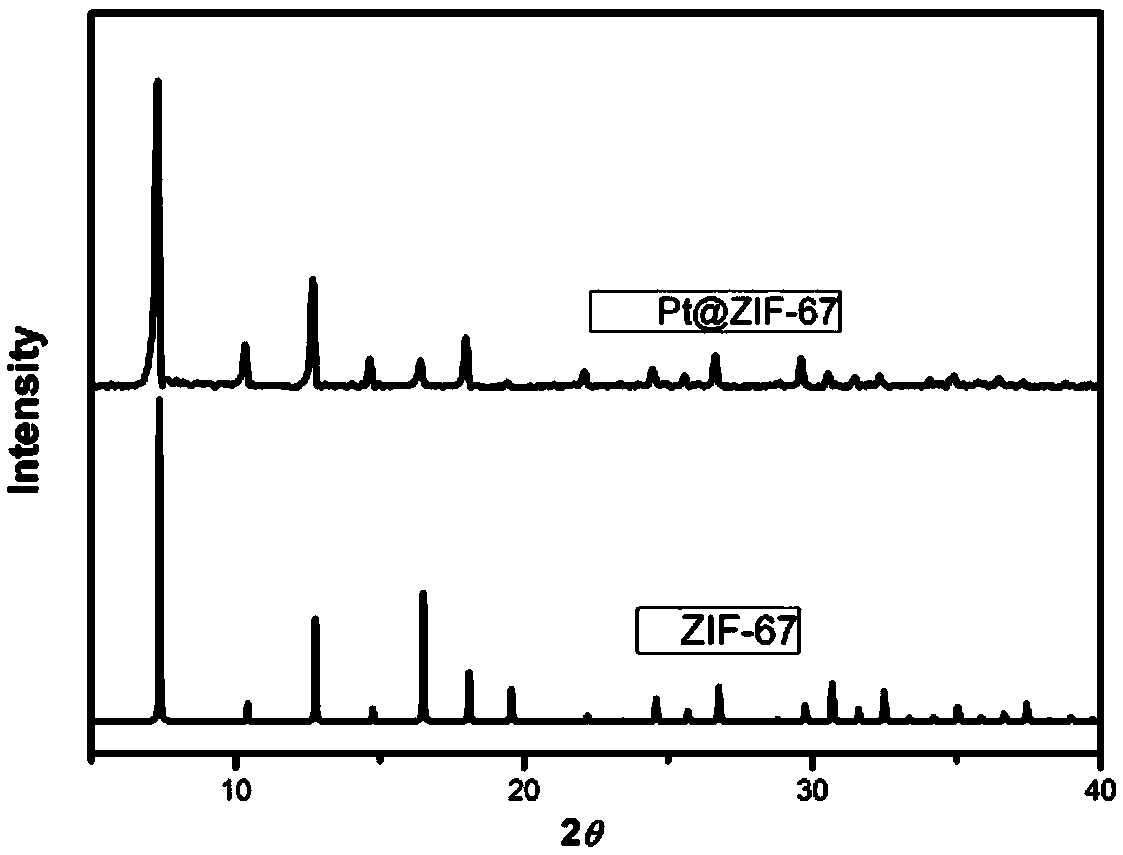

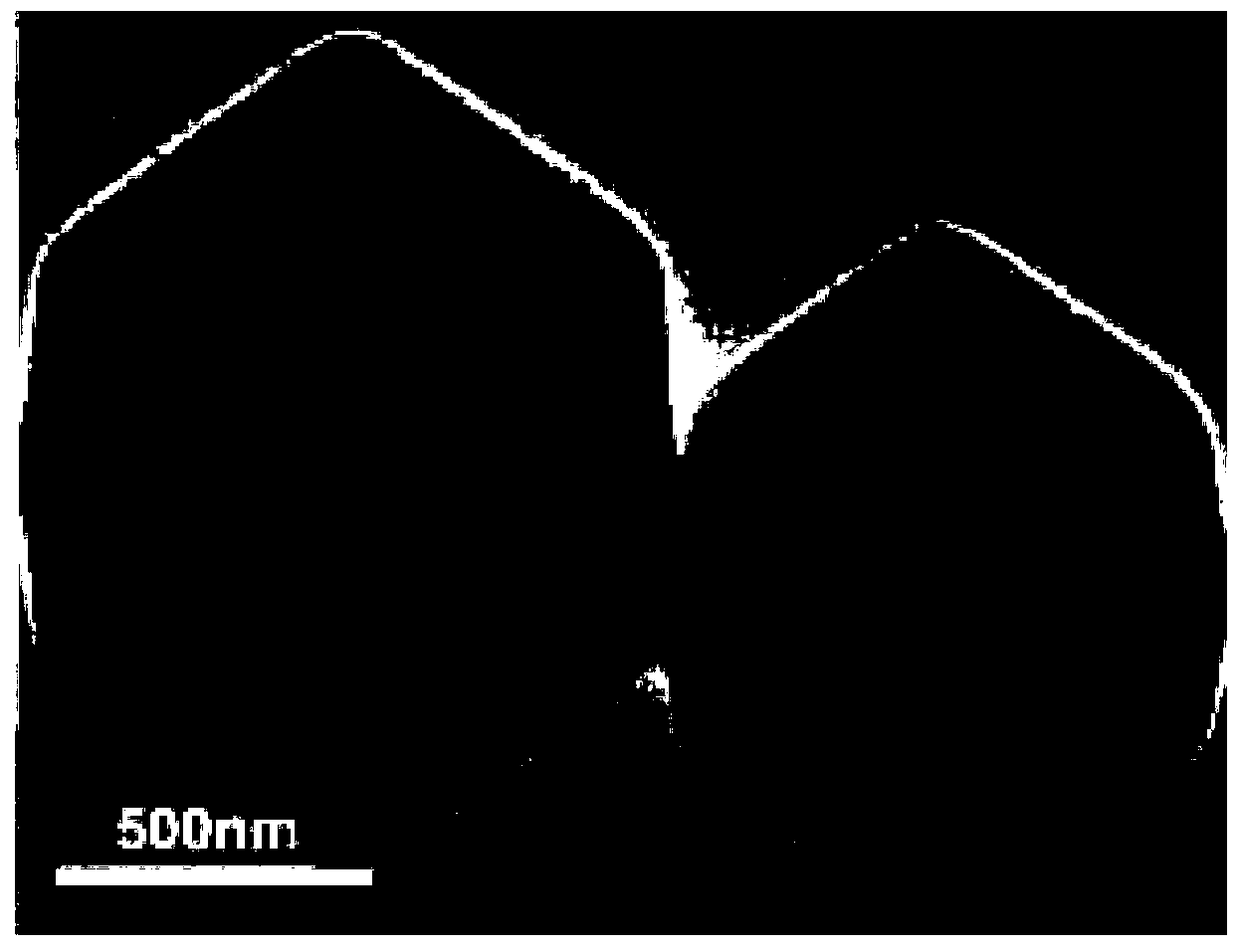

[0035] Under normal temperature and pressure, 32.84mg 2-methylimidazole, 58.205mg Co(NO 3 ) 2 ·6H 2 O and 0.3 mL pvp-dispersed methanol solution of Pt nanoparticles of about 3 nm were mixed at room temperature for 24 h, and the resulting precipitate was washed, centrifuged, and dried to obtain Pt@ZIF-67. Among them, pvp dispersed about Pt nanoparticles such as figure 1 As shown, the XRD pattern of Pt@ZIF-67 is as follows figure 2 As shown, the TEM image of the TEM image of Pt@ZIF-67 is shown in image 3 shown.

[0036] Pt@ZIF-67 as catalyst for catalytic reaction

[0037] The Pt@ZIF-67 catalyst was weighed and activated in a vacuum oven at 120°C for 10 hours, and 15 mg of the activated Pt@ZIF-67 catalyst was placed in a polytetrafluoroethylene lining, 15 mL of methanol was added as a solvent, and the catalyst was dispersed by ultrasonication for 10 minutes. uniform; then add 100 μL citronellal and a magnetic stirrer, assemble...

Embodiment 2

[0039] Preparation of Pd@ZIF-67 Catalyst

[0040] The preparation method of the Pd@ZIF-67 catalyst is the same as in Example 1, only the Pt nanoparticles are replaced with Pd nanoparticles.

[0041] The Pt@ZIF-67 catalyst was weighed and activated in a vacuum oven at 100°C for 12 hours, and 15 mg of the activated Pd@ZIF-67 catalyst was weighed in a polytetrafluoroethylene lining, and 15 mL of methanol was added as a solvent. The catalyst was evenly dispersed; then 100 μL of citronellal and a magnetic stirrer were added to assemble the autoclave and hydrogen gas was introduced. The reaction conditions were set as follows: hydrogen pressure 0.1MPa, temperature 150°C, stirring speed 800rpm, reaction time 10h. Using GC to detect citronellal and its hydrogenation products, the results are: the conversion rate is about 85%, and the selectivity of the main product citronellol is >90%.

Embodiment 3

[0043] Preparation of Pt@ZIF-8 catalyst

[0044] Under normal temperature and pressure, 15mL 2-methylimidazole (25mM), 15mL Co(NO 3 ) 2 ·6H 2 O (25 mM) and 1 mL pvp-dispersed Pt nanoparticles methanol solution of about 1 nm were mixed at room temperature for 24 h, and the resulting precipitate was washed, centrifuged, and dried to obtain Pt@ZIF-8.

[0045] Among them, the SEM image of Pt@ZIF-8 is as follows Figure 4 As shown, the TEM image of Pt@ZIF-8 is as follows Figure 5 As shown, it can be seen from the data that Pt is uniformly wrapped into MOFs, and different kinds of catalysts with good performance are obtained.

[0046] Pt@ZIF-8 as catalyst for catalytic reaction

[0047] The Pt@ZIF-8 catalyst was weighed and activated in a vacuum oven at 110°C for 11 hours in a vacuum. Weighed 15 mg of the activated Pt@ZIF-8 catalyst into a polytetrafluoroethylene lining, added 15 mL of methanol as a solvent, and ultrasonicated for 10 minutes. The catalyst was evenly dispersed;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com