Low-viscosity, anti-cracking and high-strength wet-spraying concrete and preparation method thereof

A high-strength technology of wet shotcrete, which is applied in the field of low-viscosity crack-resistant high-strength wet shotcrete and its preparation, can solve the difficulties in meeting the needs of rapid support of cavern structures, increasing the amount of sprayed concrete cementitious materials, and difficult to meet pumping requirements. In order to achieve the effect of reducing the risk of cracking, good construction performance and expanding the spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

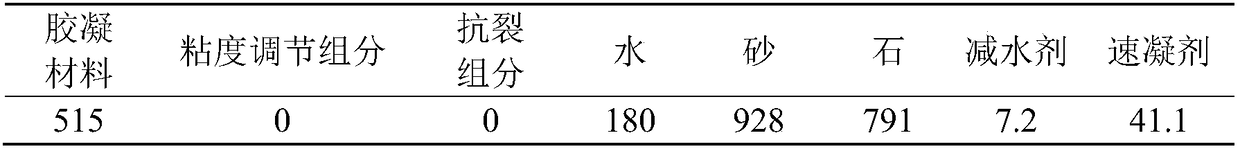

[0058] The composition ratio of the materials is shown in Table 1.

[0059] Table 1 The base mix ratio (kg / m) of the anti-cracking component and the viscosity adjusting component 3 )

[0060]

[0061] The water-binder ratio of the wet sprayed concrete is 0.35, the cement used is P O42.5, the mineral powder is S95 grade, nano-SiO 2 The volume average particle diameter D (4,3) The sand is machine-made sand with a fineness modulus of 2.8, the stone is artificial gravel of 5mm to 10mm, the water reducing agent is a high-performance water reducing agent with a water reducing rate of 28%, and the non-alkali liquid quick-setting agent has a compressive strength of 28d The ratio is 124%. Cement, nano-SiO in cementitious materials 2 The mixing ratio of mineral powder and slag is 90:5:5, and anti-cracking and viscosity-reducing measures are not used. It is used as the base mixing ratio, and the number is 1.

Embodiment 2

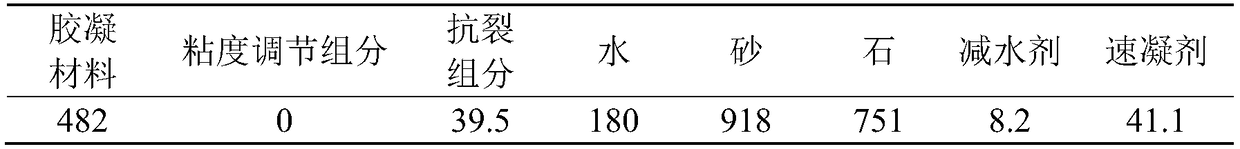

[0063] The composition ratio of the materials is shown in Table 2.

[0064] Table 2 The base mix ratio (kg / m 3 )

[0065]

[0066] The water-binder ratio of the wet sprayed concrete is 0.35, the cement used is P O42.5, the mineral powder is S95 grade, nano-SiO 2 The volume average particle diameter D (4,3) The sand is 73nm, the sand is machine-made sand with a fineness modulus of 2.8, the stone is artificial gravel of 5mm to 10mm, the water reducing agent is a high-performance water reducing agent with a water reducing rate of 28%, and the non-alkali liquid quick-setting agent has a compressive strength of 28d The ratio is 124%. Cement, nano-SiO in cementitious materials 2The mixing ratio of mineral powder and mineral powder is 79:10:11. The mixing ratio of the expansion component, the internal maintenance component and the hybrid synthetic fiber in the anti-cracking component is 60:1:16, and the expansion component used is a modified rosin resin acid-coated calcium ox...

Embodiment 3

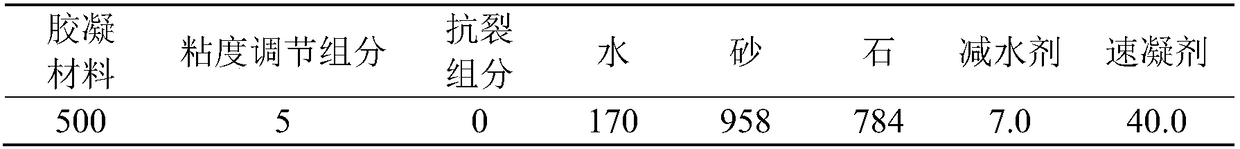

[0068] The composition ratio of materials is shown in Table 3.

[0069] Table 3 The basic mixing ratio (kg / m) of adding viscosity adjustment components and not mixing anti-cracking components 3 )

[0070]

[0071] The water-binder ratio of the wet sprayed concrete is 0.35, the cement used is P·O 42.5, the mineral powder is S95 grade, nano-SiO 2 The volume average particle diameter D (4,3) The sand is 75nm, the sand is machine-made sand with a fineness modulus of 2.8, the stone is artificial gravel of 5mm to 10mm, the water reducing agent is a high-performance water reducing agent with a water reducing rate of 28%, and the non-alkali liquid quick-setting agent has a compressive strength of 28d The ratio is 124%. Cement, nano-SiO in cementitious materials 2 The mixing ratio of mineral powder and mineral powder is 85:8:7. Added a certain amount of viscosity adjusting components, the viscosity adjusting components are methallyl alcohol ether, sodium methacrylate, alkoxy po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com