Gear machining process

A processing technology and gear technology, applied in the field of gear processing technology, can solve the problems of single gear material, low strength and low service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

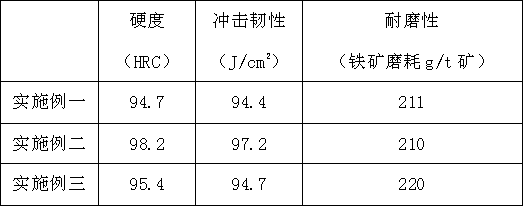

Embodiment 1

[0023] A gear processing technology provided by the present invention is characterized in that it includes the following steps:

[0024] S1, prepare the raw materials for making gears, including the following raw materials by weight: 11 parts by weight of C, 5 parts by Cr, 950 parts by Fe, 22 parts by Mo, 6 parts by Ni, 27 parts by Ti, 14 parts by Nb, 4 parts by Be, 4 parts by Ta , Zr 4 parts, V 4 parts, W 4 parts, aluminum nitride 4 parts, rare earth elements 5.5 parts, nano-zirconium dioxide 5.5 parts, surface treatment agent 17 parts, nitrogen 65 parts;

[0025] S2: Put C, Cr, Fe, Mo, Ni, Ti, Nb, Be, Ta, Zr, V, W, aluminum nitride, rare earth elements, and nano-zirconia into the grinder and pulverize them separately. Obtain the respective powder raw materials;

[0026] S3, charge C, Cr, Fe, Mo, Ni, Ti, Nb, Be, Ta, Zr, V, W, aluminum nitride, rare earth elements and nano-zirconia powder raw materials into a high-speed mixer at a temperature of Stir and mix at a speed of 300r / min ...

Embodiment 2

[0033] A gear processing technology provided by the present invention is characterized in that it includes the following steps:

[0034] S1, prepare the raw materials for making gears, including the following raw materials by weight: 11 parts by weight of C, 5 parts by Cr, 950 parts by Fe, 22 parts by Mo, 6 parts by Ni, 27 parts by Ti, 14 parts by Nb, 4 parts by Be, 4 parts by Ta , Zr 4 parts, V 4 parts, W 4 parts, aluminum nitride 4 parts, rare earth elements 5.5 parts, nano-zirconium dioxide 5.5 parts, surface treatment agent 17 parts, nitrogen 65 parts;

[0035] S2: Put C, Cr, Fe, Mo, Ni, Ti, Nb, Be, Ta, Zr, V, W, aluminum nitride, rare earth elements, and nano-zirconia into the grinder and pulverize them separately. Obtain the respective powder raw materials;

[0036] S3, charge C, Cr, Fe, Mo, Ni, Ti, Nb, Be, Ta, Zr, V, W, aluminum nitride, rare earth elements and nano-zirconia powder raw materials into a high-speed mixer at a temperature of Stir and mix at a speed of 300r / min ...

Embodiment 3

[0043] A gear processing technology provided by the present invention is characterized in that it includes the following steps:

[0044] S1, prepare the raw materials for making gears, including the following raw materials by weight: 11 parts by weight of C, 5 parts by Cr, 950 parts by Fe, 22 parts by Mo, 6 parts by Ni, 27 parts by Ti, 14 parts by Nb, 4 parts by Be, 4 parts by Ta , Zr 4 parts, V 4 parts, W 4 parts, aluminum nitride 4 parts, rare earth elements 5.5 parts, nano-zirconium dioxide 5.5 parts, surface treatment agent 17 parts, nitrogen 65 parts;

[0045] S2: Put C, Cr, Fe, Mo, Ni, Ti, Nb, Be, Ta, Zr, V, W, aluminum nitride, rare earth elements, and nano-zirconia into the grinder and pulverize them separately. Obtain the respective powder raw materials;

[0046] S3, charge C, Cr, Fe, Mo, Ni, Ti, Nb, Be, Ta, Zr, V, W, aluminum nitride, rare earth elements and nano-zirconia powder raw materials into a high-speed mixer at a temperature of Stir and mix at a speed of 300r / min ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com