Catalyst and method for alcoholysis of polycarbonate

A technology of polycarbonate and catalyst, which is applied in the field of polycarbonate alcoholysis reaction, can solve the problems such as the catalytic effect needs to be improved, the amount of catalyst used is large, and cannot be biodegraded, and the effect of simple production, simple synthesis method and low cost can be achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

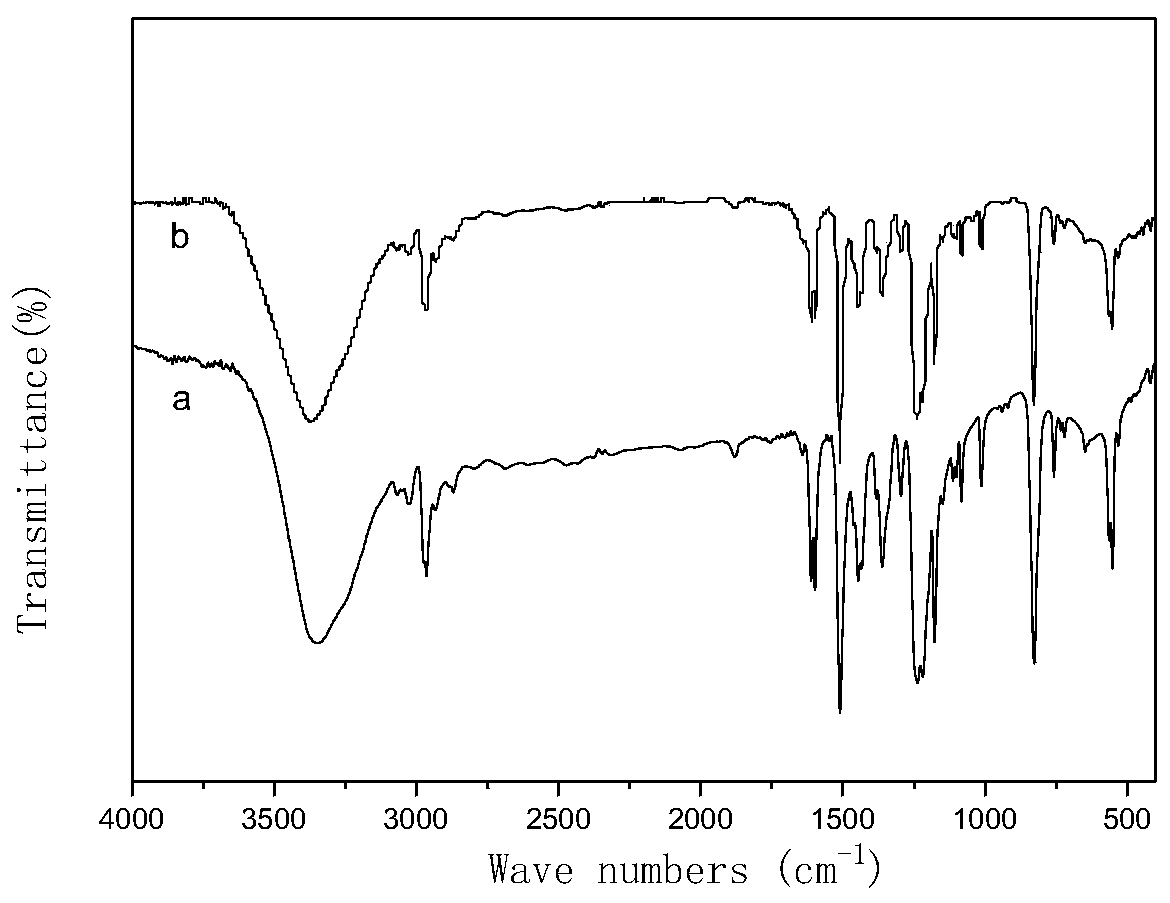

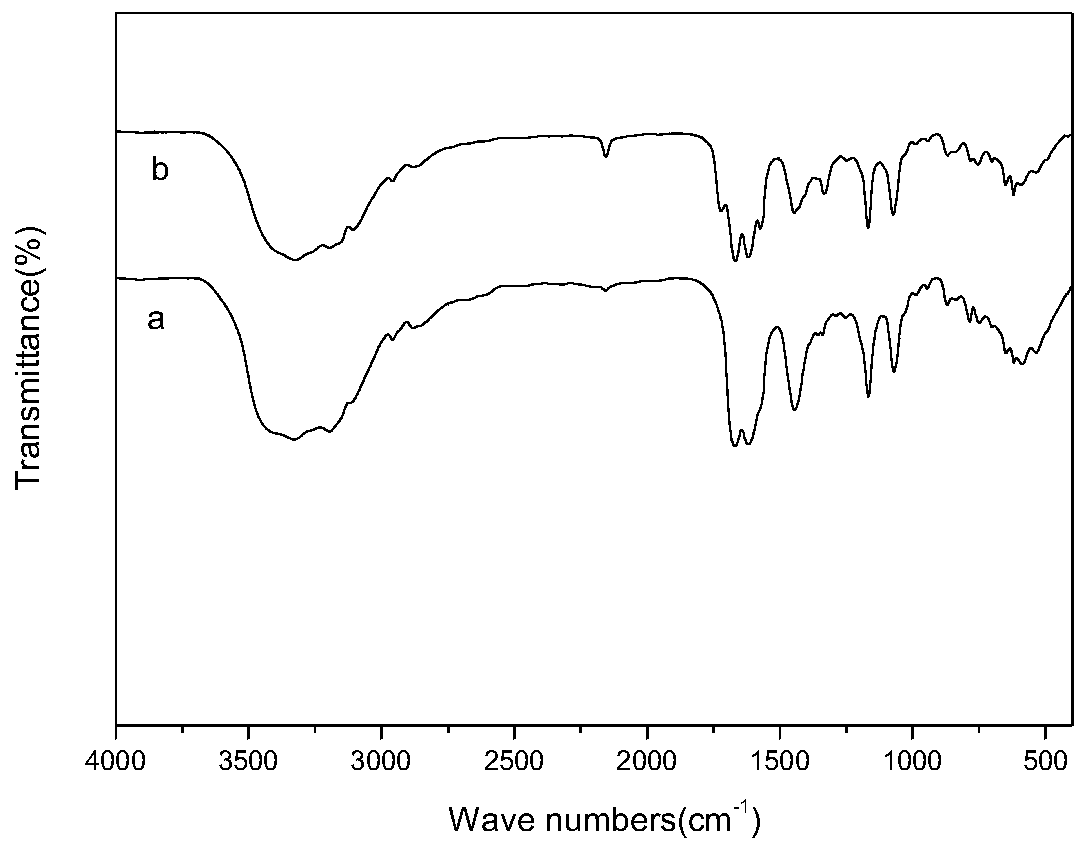

[0020] The preparation of embodiment 1[EMIMOH]Cl-nUrea deep eutectic solvent

[0021] Preparation of N-methylimidazole precursor Add N-methylimidazole and 2-chloroethanol at a molar ratio of 1:1 to a three-necked flask successively, heat to reflux under nitrogen atmosphere, stir for 48 hours, and cool naturally to room temperature. A large amount of white precipitate appeared at the bottom, and the white precipitate was filtered with a Buchner funnel, washed several times with ethyl acetate, and the resulting white precipitate was dried in a vacuum oven at 80°C for 8 hours to obtain a white N-methylimidazole precursor.

[0022] Preparation of [EMIMOH]Cl-nUrea deep eutectic solvent Take the above-mentioned N-methylimidazole precursor and urea with a molar ratio of 1:2, add them to a 100ml single-necked bottle, and heat and stir at 90°C for 2h under a nitrogen atmosphere. Until the colorless transparent clear liquid generates [EMIMOH]Cl-2Urea.

Embodiment 2

[0023] The preparation of embodiment 2[EMIMOH]Cl-nUrea deep eutectic solvent

[0024] Preparation of N-methylimidazole precursor Add N-methylimidazole and 2-chloroethanol at a molar ratio of 1:1 to a three-necked flask successively, heat to reflux under nitrogen atmosphere, stir for 48 hours, and cool naturally to room temperature. A large amount of white precipitate appeared at the bottom, and the white precipitate was filtered with a Buchner funnel, washed several times with ethyl acetate, and the resulting white precipitate was dried in a vacuum oven at 80°C for 8 hours to obtain a white N-methylimidazole precursor.

[0025] Preparation of [EMIMOH]Cl-nUrea deep eutectic solvent Take the above-mentioned N-methylimidazole precursor and urea with a molar ratio of 1:5, add them to a 100ml single-necked bottle, and heat and stir at 90°C for 2h under a nitrogen atmosphere. Until the colorless transparent clear liquid generates [EMIMOH]Cl-5Urea.

Embodiment 3

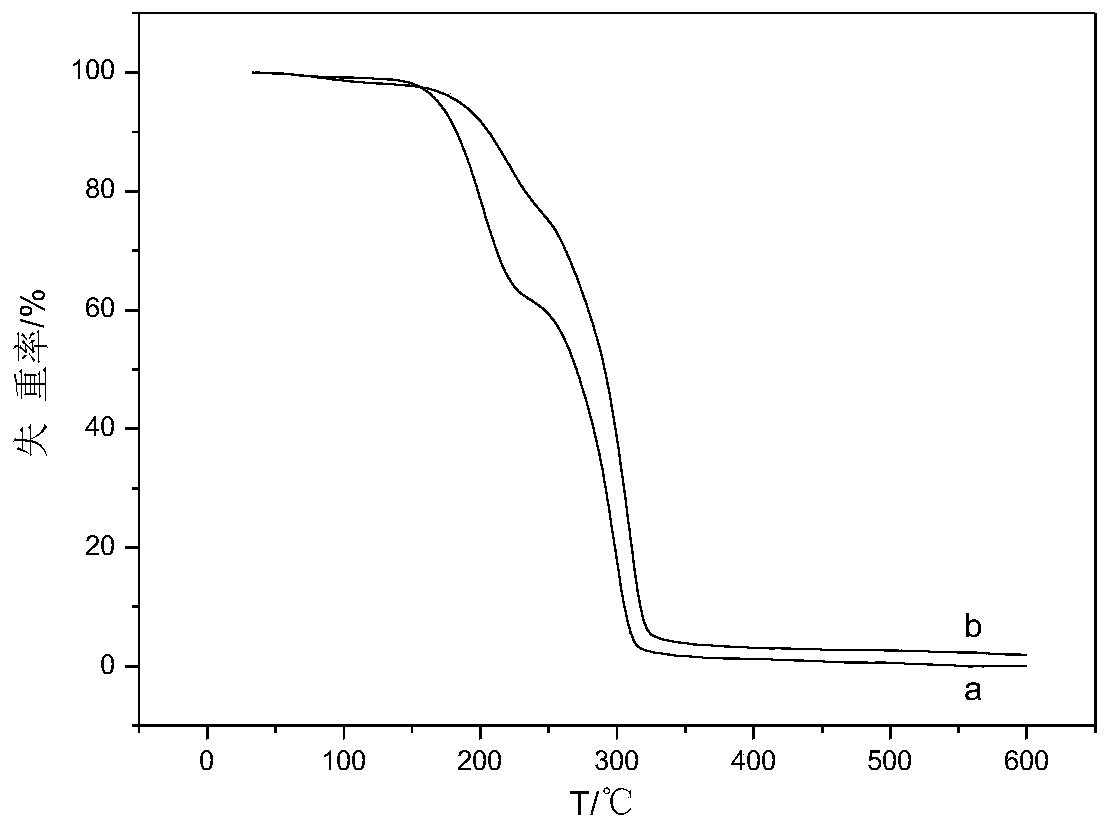

[0026] The influence of the proportioning of embodiment 3 [EMIMOH]Cl-nUrea on PC alcoholysis reaction

[0027] In an autoclave with a thermometer, 4 g of waste PC, 0.4 g of [EMIMOH]Cl-nUrea in Table 1, and 2.5 g of methanol were sequentially added, and the reaction was stirred at 120°C for 2 hours. The PC residue of the reaction, the filtrate was distilled under reduced pressure first, and then ethyl acetate and deionized water were added to extract and separate the liquid. Obtain corresponding product BPA after pressure distillation, the yield of corresponding product BPA and PC degradation rate are as shown in table 1.

[0028]Table 1 Effect of the ratio of choline chloride DES on the alcoholysis reaction of PC

[0029]

[0030] The data in Table 1 show that the molar ratio of [EMIMOH]Cl to Urea is 1:1 to 1:5, which has a good catalytic effect on the methanolysis reaction of PC, and the degradation rate of PC can reach 100%, but [ EMIMOH]Cl-2Urea has a better catalytic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com