Deep dehydration closed acid scrubbing purification process

A deep dehydration and purification process technology, applied in the direction of inorganic chemistry, sulfur compounds, sulfur trioxide/sulfuric acid, etc., can solve the problem of large gas flow and achieve the effect of ensuring water balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

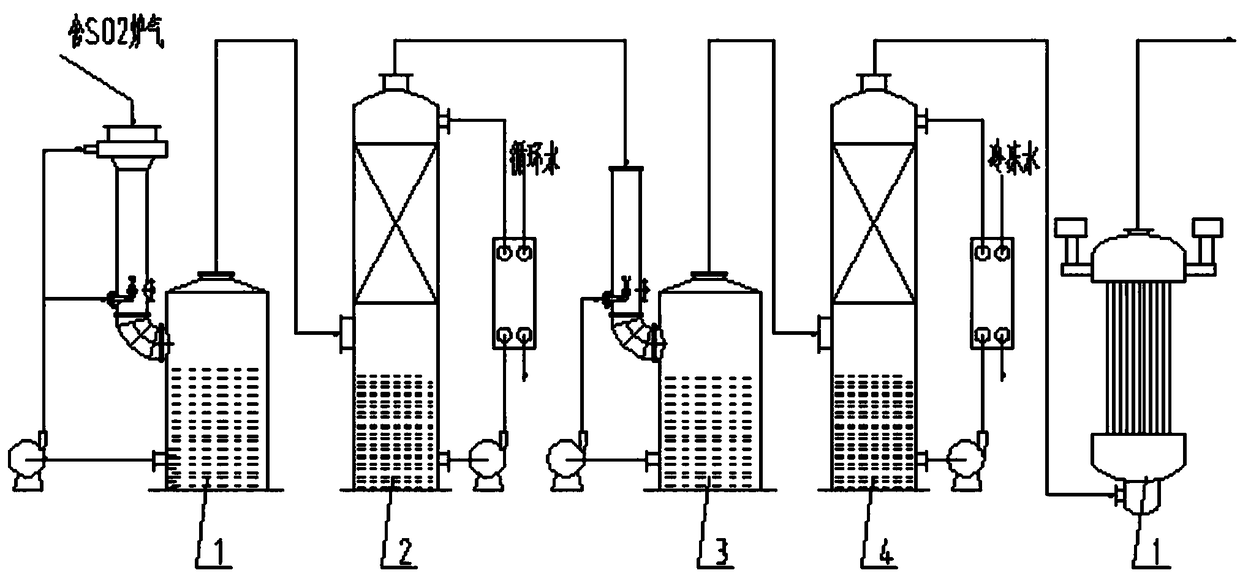

[0017] see figure 1 , the invention belongs to the technical field of chemical production, and is applicable to regenerated lead, molybdenum concentrate, etc. containing SO 2 The gas purification section for the production of sulfuric acid from smelting flue gas.

[0018] After the smelting flue gas of secondary lead and molybdenum concentrate is subjected to dry dust removal, the flue gas exiting the dry dust removal equipment is cooled and dehydrated by the first-level power wave scrubber, gas scrubber, second-level power wave scrubber, and deep gas cooling tower. And electric demister, after removing water mist, water droplets, acid mist, dust, etc., go to the dry suction section of sulfuric acid production.

[0019] In the present invention, the moisture in the furnace gas in the sulfuric acid production and purification section is deeply cooled, changed from a gaseous state to a liquid state, and discharged out of the system along with the dilute acid, which ensures the ...

Embodiment 2

[0040] Molybdenum concentrate flue gas, gas volume 33000Nm 3 / h, temperature 250 degrees. Entering the first-stage dynamic wave scrubber, the gas composition is shown in Table 5:

[0041] table 5

[0042] Element

Gas volume kmol / h

Air volumekg / h

Capacity Nm 3 / h

SO 2

2.85

41.98660714

2687.142857

940.5

SO 3

0.1

1.473214286

117.8571429

33

CO 2

0

0

0

0

h 2 o

11

162.0535714

2916.964286

3630

O 2

12

176.7857143

5657.142857

3960

N 2

73.4

1081.339286

30277.5

24222

total

100

1473.214286

41656.60714

33000

[0043] Enter the gas scrubber at 62 degrees, and the gas composition is shown in Table 6:

[0044] Table 6

[0045] Element

Gas volume kmol / h

Air volumekg / h

Capacity Nm 3 / h

SO 2

2.5499

41.9866

2687....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com