Filter barrel assembly structure of purifier

A component structure and filter barrel technology, which is applied in the direction of dispersed particle filtration, chemical instruments and methods, and dispersed particle separation, can solve the problems of inability to clean the air filter barrel, and achieve cost savings, high work efficiency, and improved service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

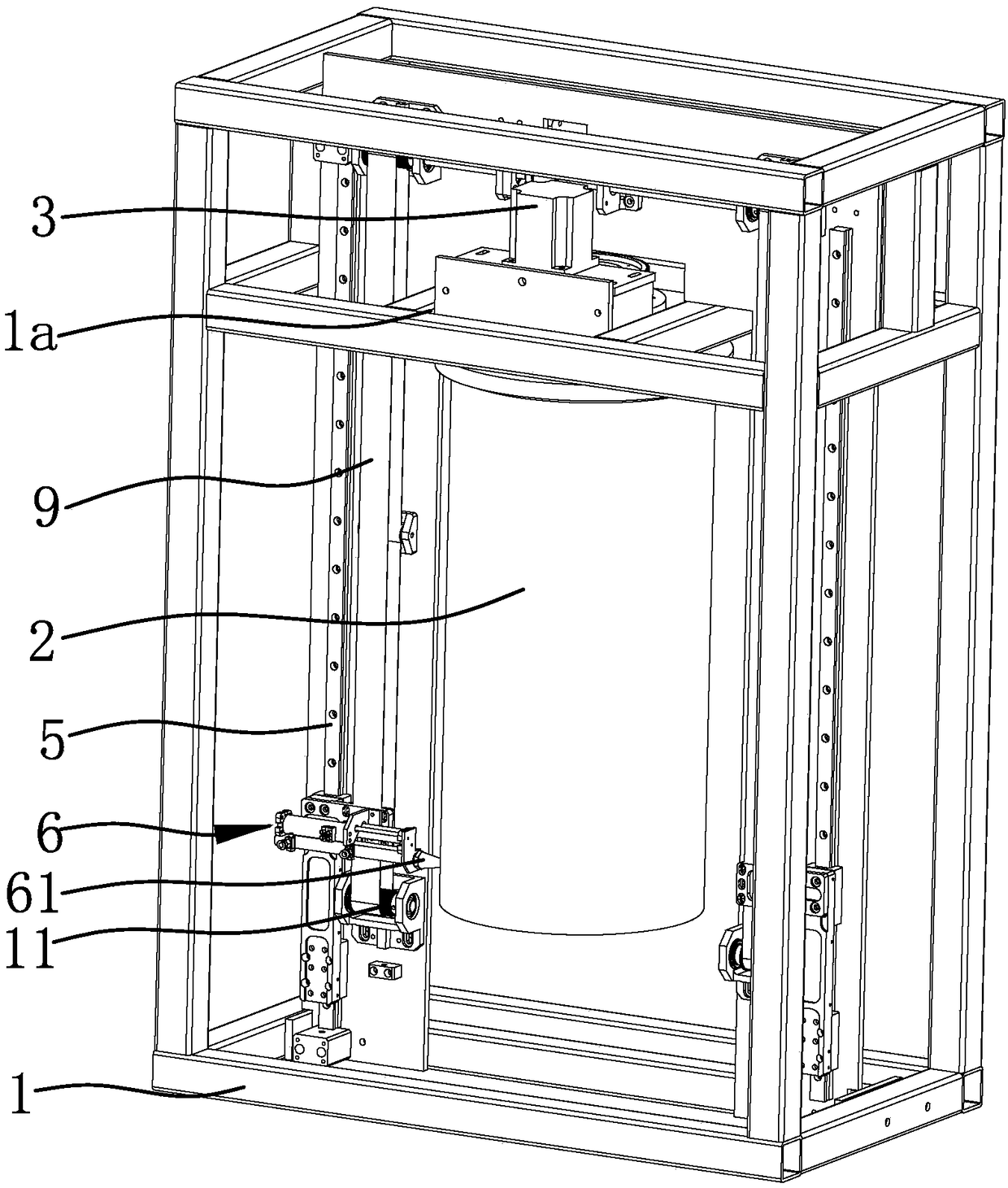

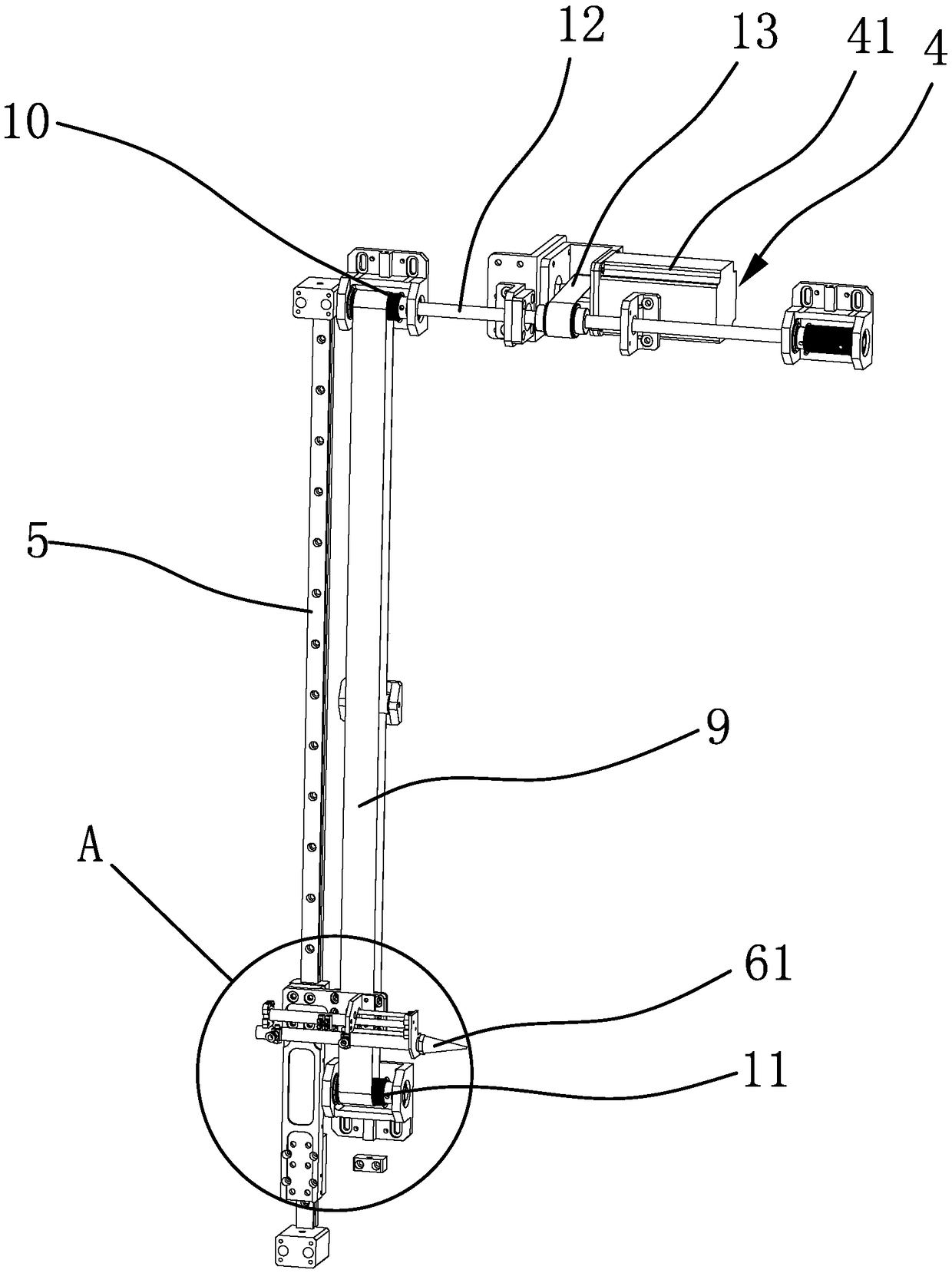

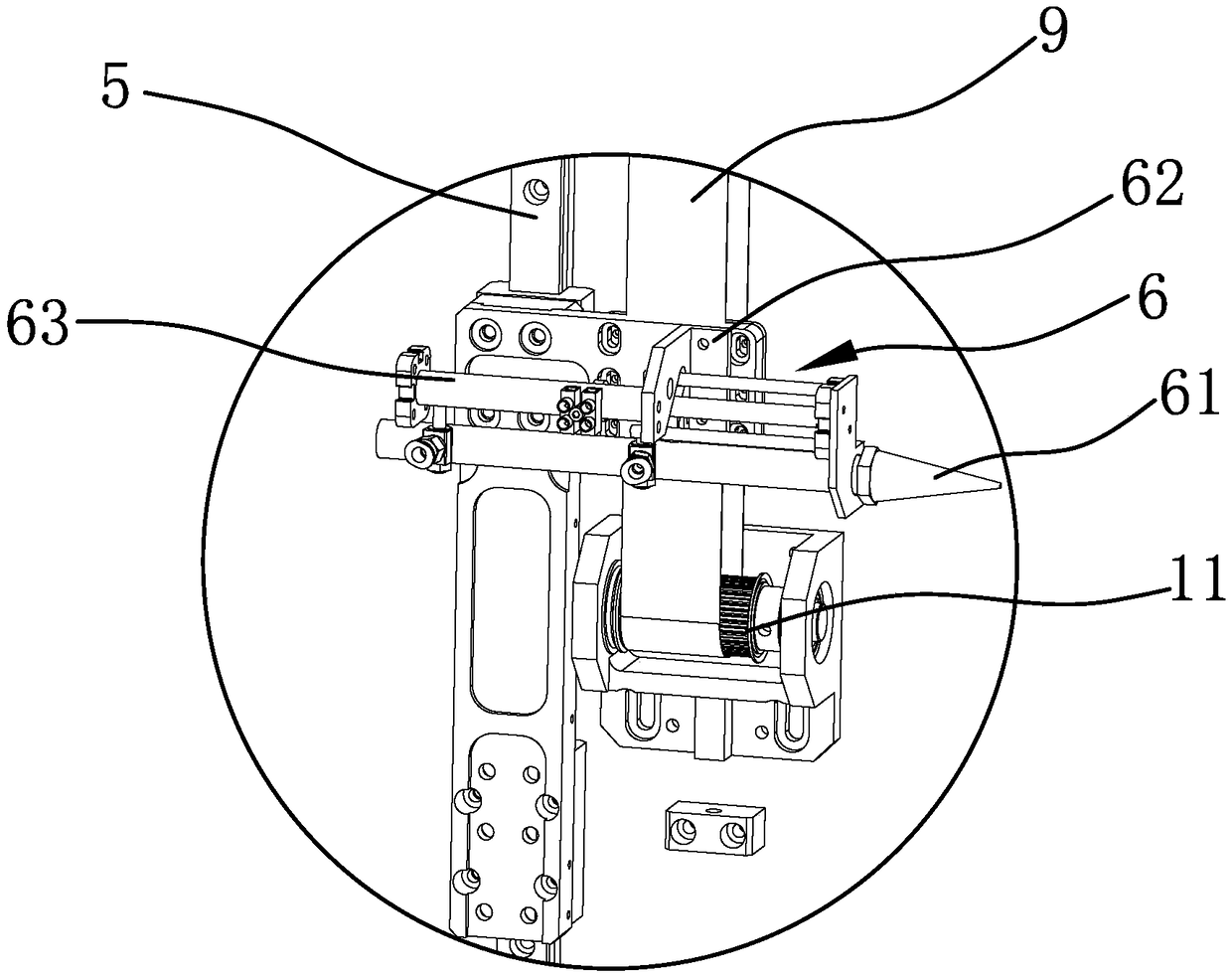

[0022] Such as Figure 1 to Figure 4 As shown, the structure of the filter barrel assembly includes a mounting frame 1 and a cylindrical filter core 2; the filter core 2 is rotatably connected to the mounting frame 1, and the mounting frame 1 is fixedly provided with a drive member-3 that can drive the filter core 2 to rotate. Mounting frame 1 is fixedly provided with guide rail 5, and guide rail 5 is positioned at the outer side of filter core 2 and is arranged along the axial direction of filter core 2, and guide rail 5 is provided with air injection device 6 slidingly, and mounting frame 1 is fixedly provided with and can drive air injection device 6 along The driving part 2 for the reciprocating movement of the guide r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com