Stacked plate heat exchanger

A technology of heat exchanger and plate stacking type, applied in the direction of heat exchanger fixing, heat exchange equipment, indirect heat exchanger, etc., can solve the problems of complicated manufacturing process, increased cost, and residual welding traces in the finished product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

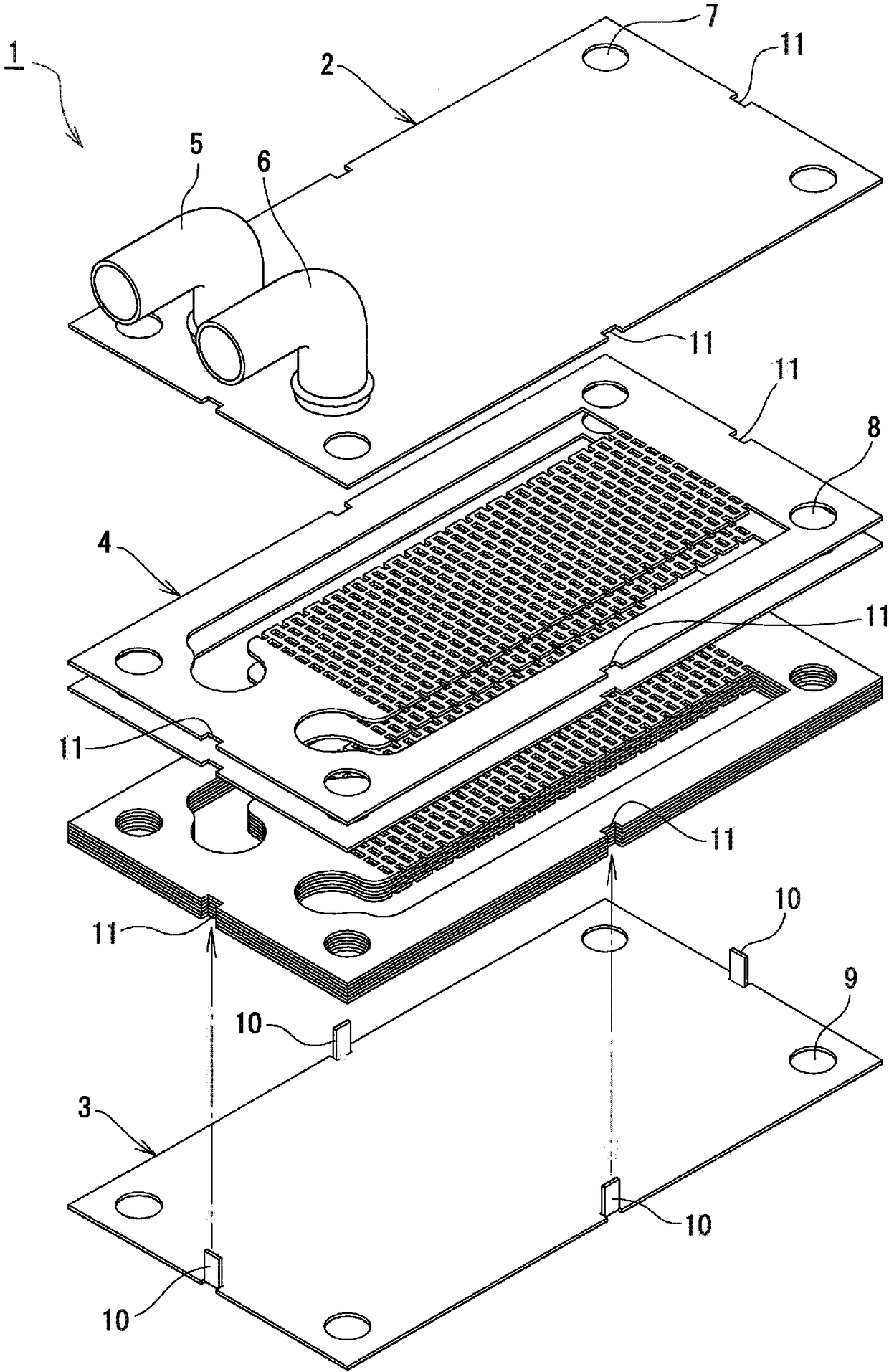

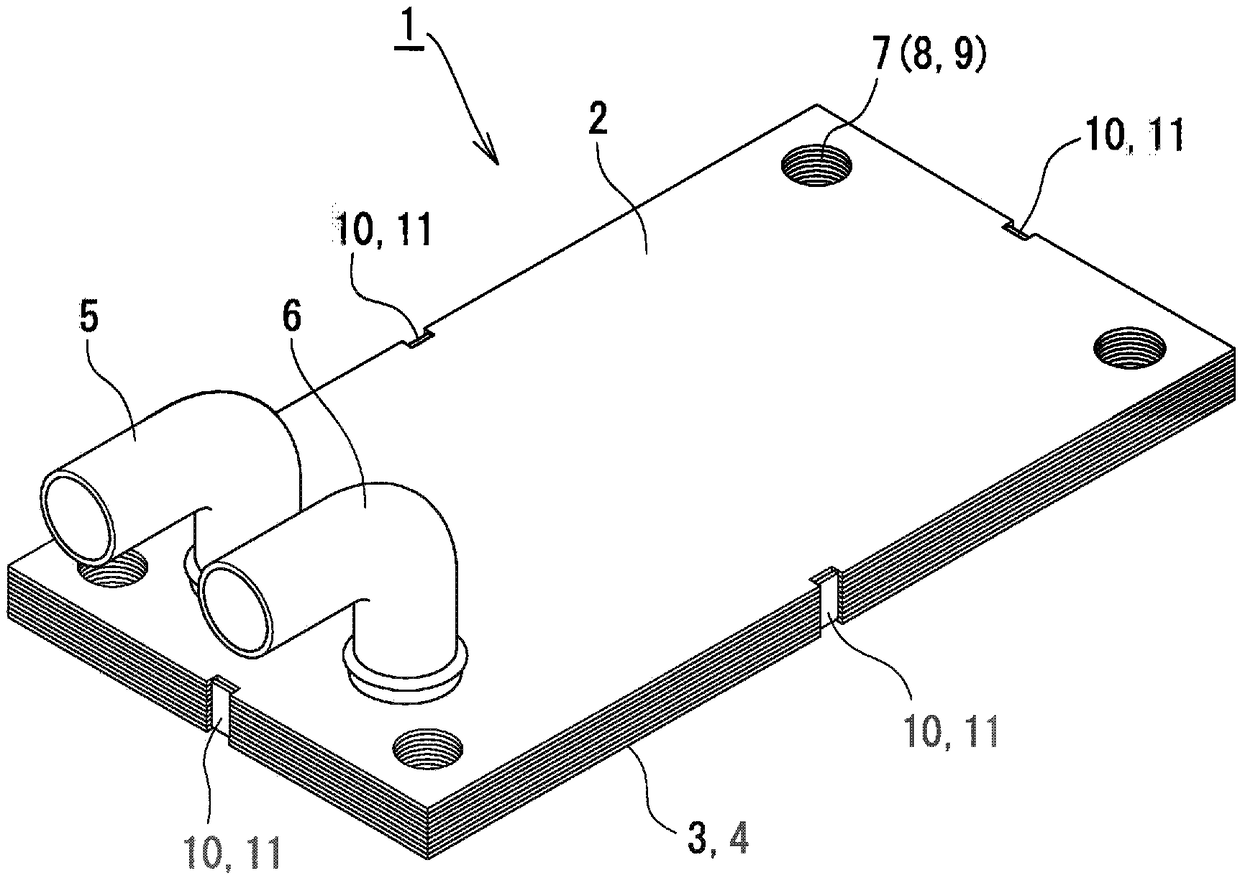

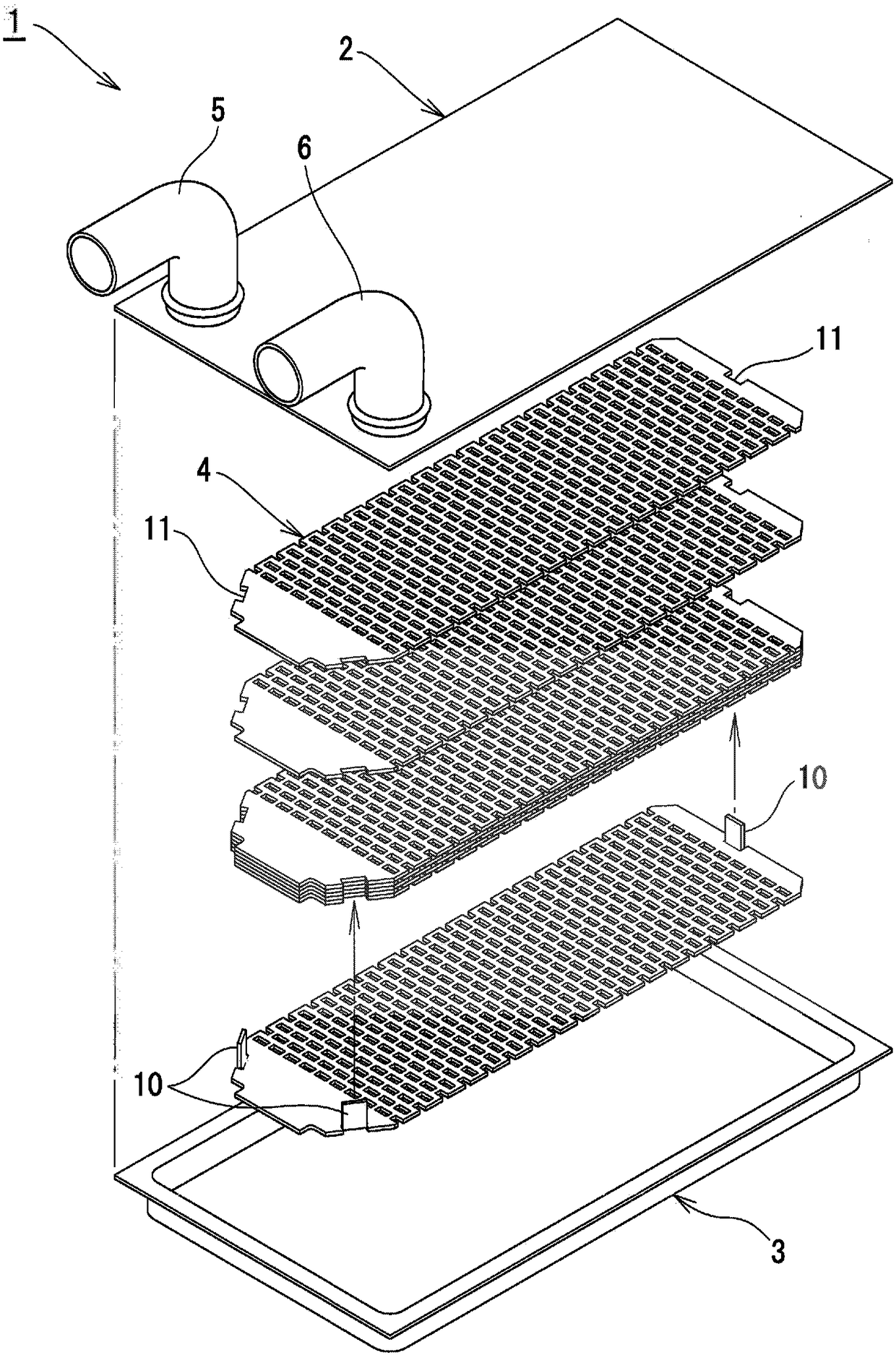

[0034] figure 1 In the first embodiment of the plate-stacked heat exchanger, each member is shown as an exploded perspective view when temporarily fixed. The heat exchanger 1 has a fully laminated structure, and includes a top plate 2, a bottom plate 3, and a plurality of inner plates 4 serving as heat exchanging parts.

[0035] The material of each plate is metal such as aluminum (including alloy) and stainless steel, and may be a non-scaling material or a coating material in which the surface of the base material is covered with solder. In addition, in the case of a non-scaling material, solder was applied and used to a joint part.

[0036] Each plate is formed in a square shape (specifically, a rectangle) in plan view. The top plate 2 has fluid inlet pipes 5 and fluid outlet pipes 6 for cooling water or the like, and bolt holes 7 for fixing the heat exchanger 1 to, for example, an object to be fixed are provided at four corners of the top plate 2 . Bolt holes 8 and 9 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com