Motor

一种电动机、转动机构的技术,应用在电动机领域,能够解决难以适当控制第一及第二转子相位、电动机控制处理复杂化、不能控制相位差等问题,达到扩大转速范围及转矩范围、抑制复杂化、实现小型化的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

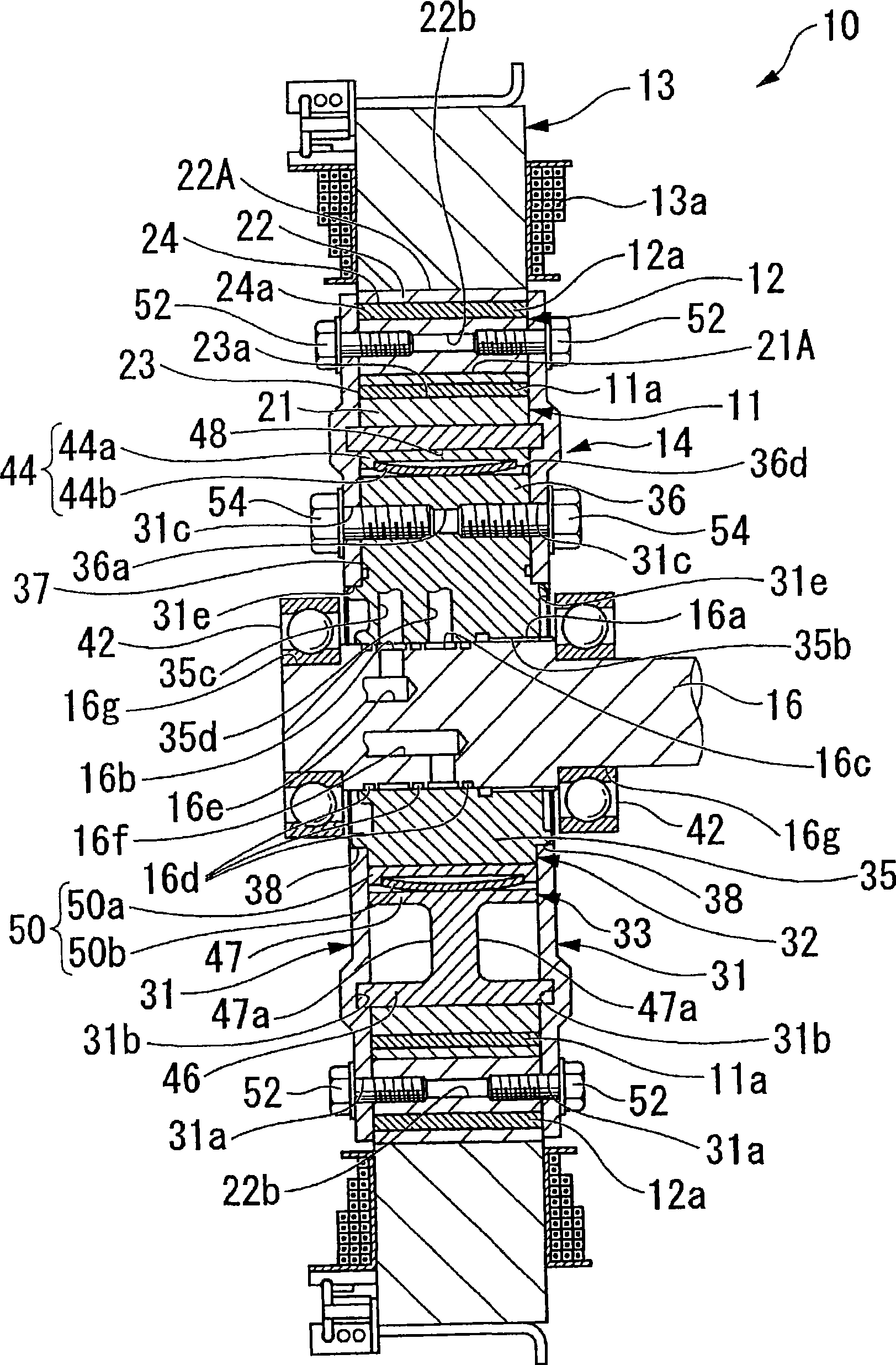

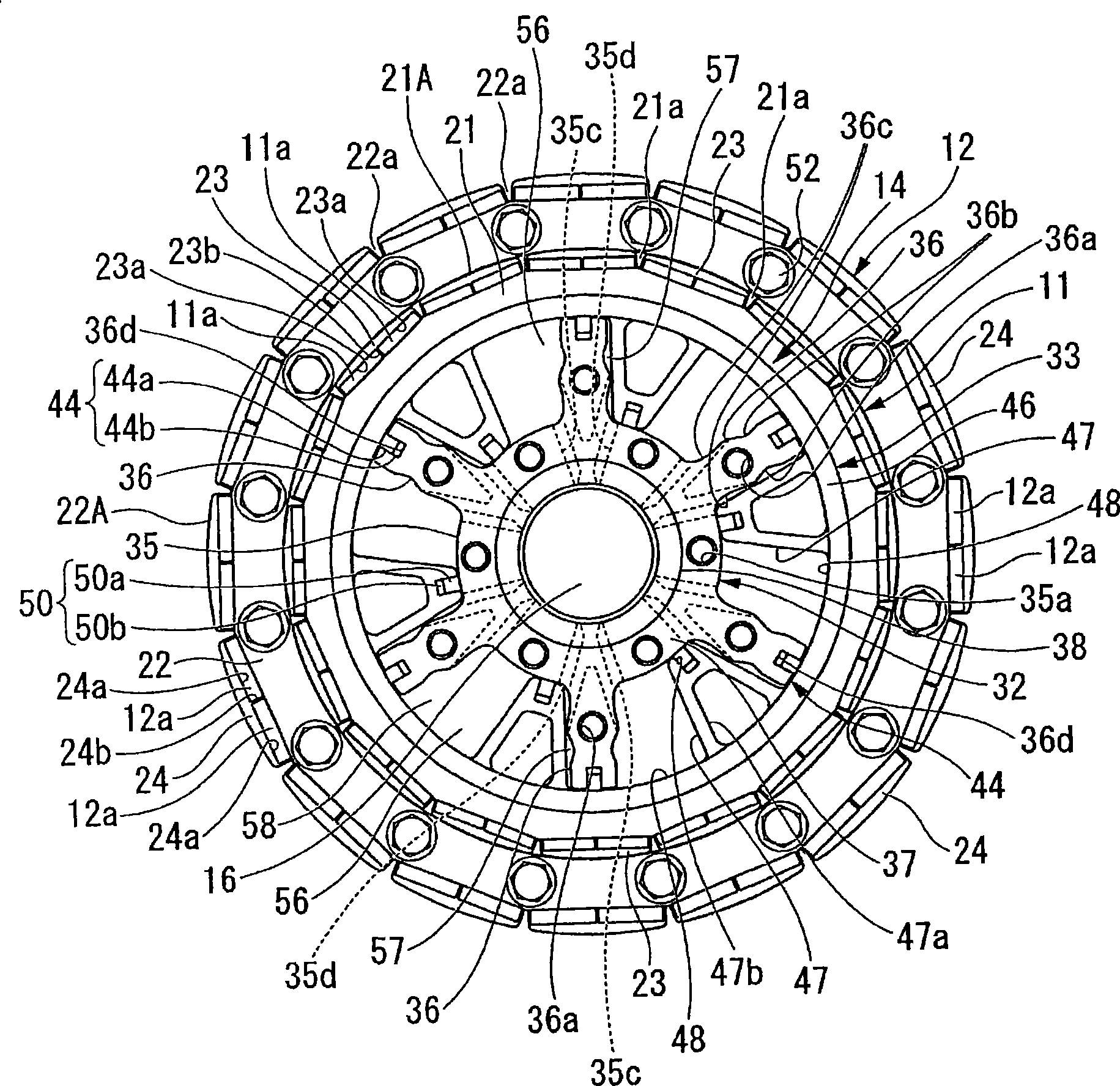

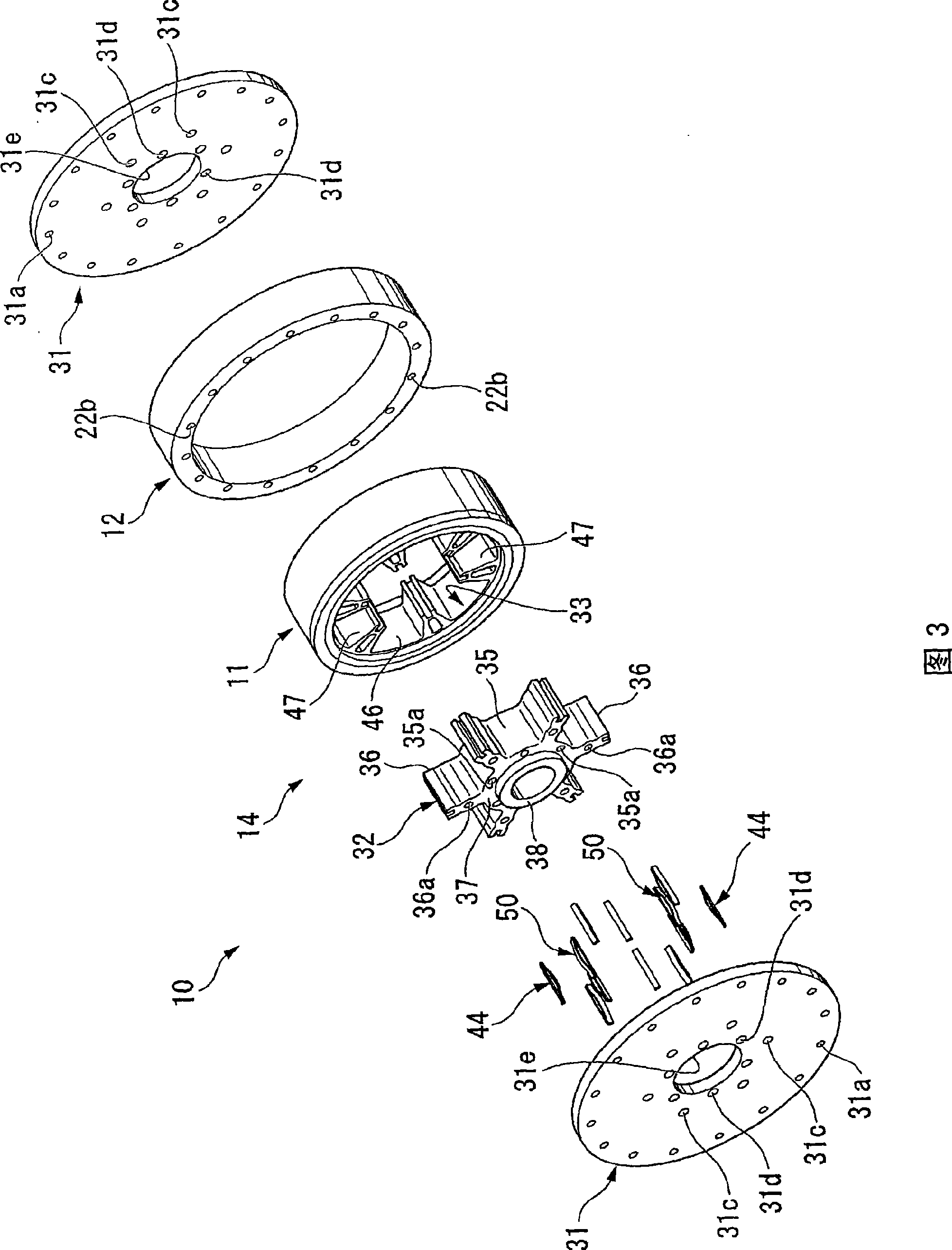

[0097] Below, refer to Figure 1 to Figure 10B A motor according to the first embodiment of the present invention will be described.

[0098] The electric motor 10 of the present embodiment is as follows figure 1 3 shows a brushless DC motor including: a substantially annular inner circumference side rotor 11 rotatably provided with the rotation axis of the motor 10 as the center; and a substantially annular annular outer circumference side rotor 12 With respect to the radially outer side of the inner circumference side rotor 11, the inner circumference side rotor 11 is provided so as to be rotatable with the coaxial rotation axis as the center, and is provided corresponding to the position in the rotation axis direction; Polyphase of the rotating magnetic field of the side rotor 12 figure 1 The shown stator winding 13a; the turning mechanism (turning device) 14, which is connected to the inner rotor 11 and the outer rotor 12, and is connected to the hydraulic pressure (flui...

no. 2 approach

[0153] Second, the main reference Figure 11 and Figure 12 , the motor according to the second embodiment of the present invention will be described focusing on the parts different from the above-described first embodiment. In addition, the same code|symbol is attached|subjected to the same part as the said 1st Embodiment, and the description is abbreviate|omitted.

[0154] In this embodiment, a part of the rotation mechanism 14 is changed from the above-described first embodiment. First, as Figure 11 As shown, one of the transmission plates 31 is fixed to the outer peripheral side rotor 12 by bolts 52, . The hub portion 35 is further fixed to the blade portion 36 of the blade rotor 32 by bolts 54 , . . . , 54 .

[0155] In contrast, the annular transmission plate 61 is disposed on the opposite side in the axial direction of the transmission plate 31 so as to cover a part of the outer peripheral sides of the outer peripheral side rotor 12 and the inner peripheral side ro...

no. 3 approach

[0161] Second, the main reference Figure 13 , the motor according to the third embodiment of the present invention will be described focusing on the differences from the first embodiment described above. In addition, the same code|symbol is attached|subjected to the same part as the said 1st Embodiment, and the description is abbreviate|omitted.

[0162] In this embodiment, the rotation mechanism 70 different from that of the above-described first embodiment is used.

[0163] The turning mechanism 70 of the present embodiment includes a pair of annular transmission plates (first members) 71 and 71 that are fixed to both sides in the axial direction of the outer circumference side rotor 12 so as to cover the space inside the outer circumference side rotor 12 ; The supporting member 73 that is integrally provided on the one transmission plate 71 and supported by the output shaft 72 of the electric motor 10; 74; An inner rotor body 75 having the same structure as the inner rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com