VCSEL chip array structure and manufacturing method thereof

A technology of chip array and manufacturing method, which is applied in the direction of laser parts, electrical components, lasers, etc., can solve the problems of limiting the minimum distance between adjacent light exit holes 3, unfavorable VCSEL, cracking, etc., so as to improve the photoelectric performance and reliability of use, Broad market promotion and application prospects, and the effect of improving polarization performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

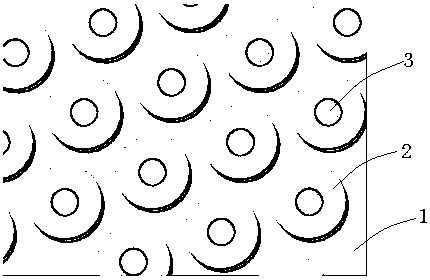

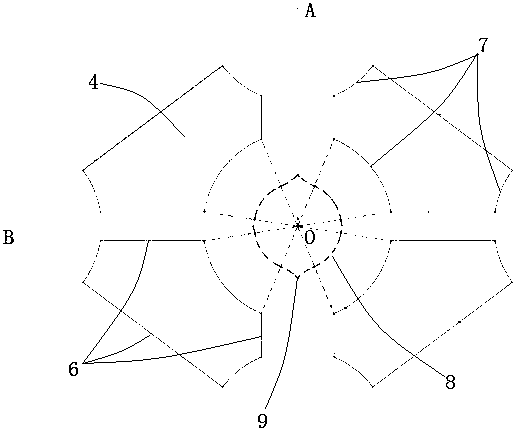

[0033] Such as figure 2 with 3 As shown, the present embodiment provides a method for manufacturing a VCSEL chip rectangular array structure, and the specific implementation steps are as follows:

[0034] First, if figure 2As shown, the right-angled triangle AOB in the rectangular array structure of the VCSEL chip is used as the basic unit, the lengths of the two right-angled sides AO and BO of the right-angled triangle AOB are 30 microns and 40 microns respectively, and the length of the hypotenuse AB of the right-angled triangle is 50 Micron, in a right triangle, with three vertices as the center, draw three arcs 7 respectively, the radius of the arc 7 is greater than 10 microns, less than half of the shortest right angle side AO 15 microns, preferably 13 microns, three in the right triangle Short line segment 6, the short line segment parallel to the right-angled side AO of 30 microns, the distance from the parallel right-angled side AO is greater than 3 microns, prefer...

Embodiment 2

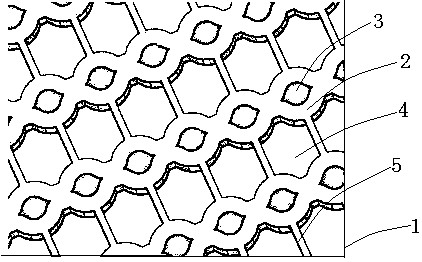

[0037] Such as Figure 4 As shown, this embodiment provides a method for manufacturing a VCSEL chip close-packed hexagonal array structure, and the specific implementation steps are as follows:

[0038] First, the equilateral triangle in the hexagonal array structure of the VCSEL chip is used as the basic unit. The length of the three sides of the equilateral triangle is 32 microns. In the equilateral triangle, with the three vertices as the center, draw three arcs respectively. The radius of the arc is greater than 10 microns, less than half of the shortest side of 16 microns, preferably 14 microns; the three short line segments in an equilateral triangle are respectively parallel to the three sides, and the distance from the parallel sides is equal, greater than 3 microns, preferably 5 microns , so that the closed polygon composed of three arcs and three short line segments makes six 60-degree rotational symmetry around any vertex of the equilateral triangle, so that six pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com