Low-loss magnetic insulation sheet preparation process and magnetic insulation sheet

A preparation process and a technology of magnetic isolation sheets, which are applied in the fields of magnetic core/yoke, inductor/transformer/magnet manufacturing, electrical components, etc., can solve problems such as difficult drying of strips, poor performance consistency, and changes in adhesive layer performance. Achieve the effects of complete functions, low production cost, and small eddy current loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

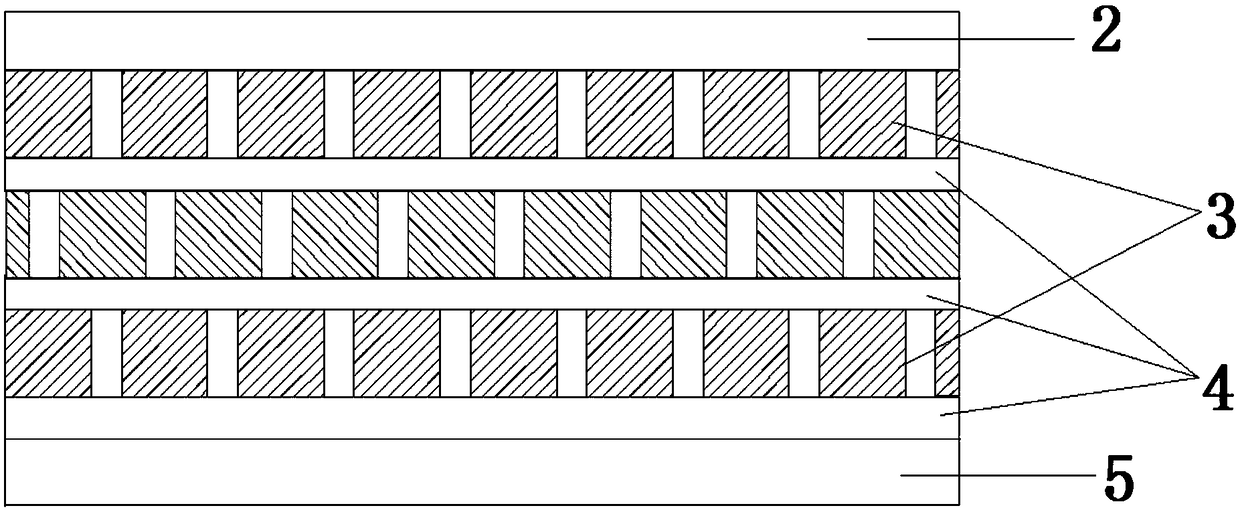

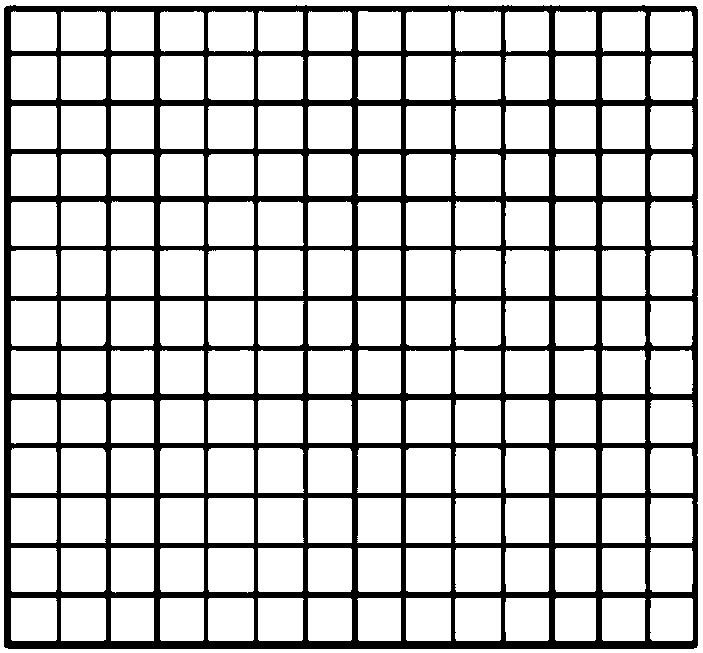

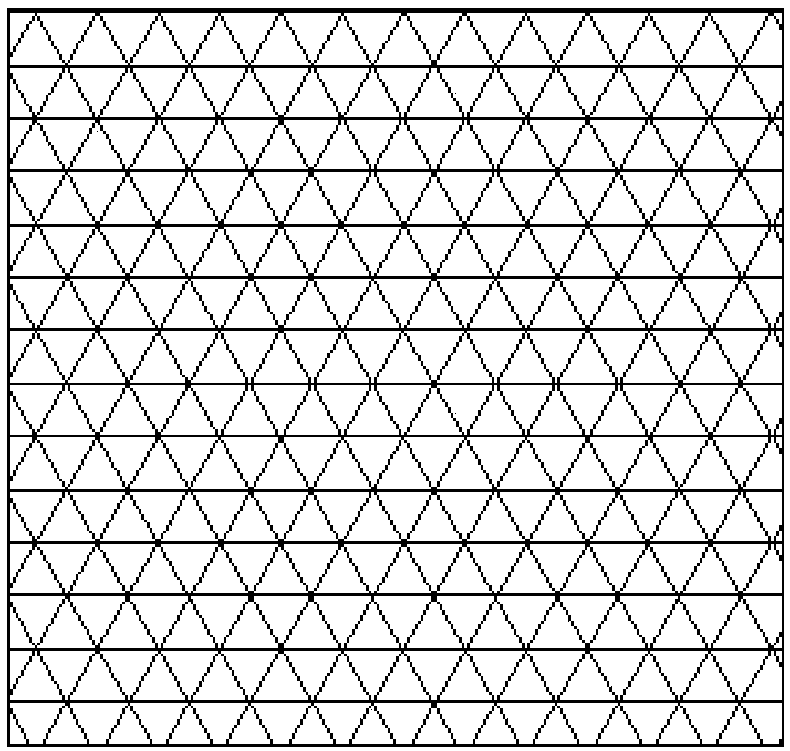

[0023] This specific embodiment adopts the following technical solutions: a low-loss magnetic isolation sheet preparation process, including the following process flow: A, raw material processing: the soft magnetic tape material is cut into a set width, and then the surface of the soft magnetic tape material is treated , and wound to the specified inner and outer diameters according to the process requirements; B. heat treatment: place the wound soft magnetic tape in a heat treatment furnace with or without a magnetic field for heat treatment; C. lamination: through roll lamination Paste the double-sided adhesive on one side of the heat-treated soft magnetic material in the same way, and the other side is exposed to form a single layer; D. Surface patterning treatment: through the single layer formed above or the soft magnetic material stacked from the above single layer into multiple layers Graphical processing of magnetic materials; E. Molding: forming low-loss magnetic isola...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com