High-performance and high-frequency responsivity ferrite-based composite having laminated structure

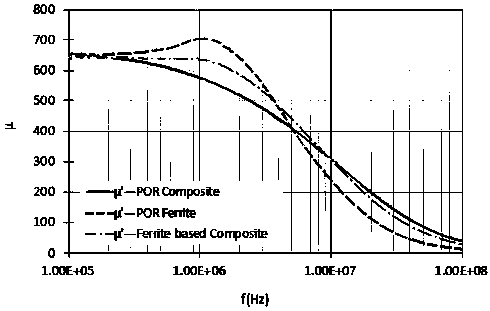

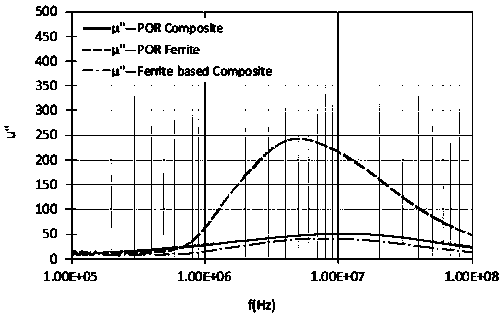

A composite magnetic material, laminated structure technology, applied in the direction of inorganic material magnetism, transformer/inductor parts, electrical components, etc., can solve the problems of poor frequency response sensitivity, low magnetic saturation strength, low magnetic permeability, etc. The effect of segment frequency response, highly sensitive frequency response, and high magnetic saturation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

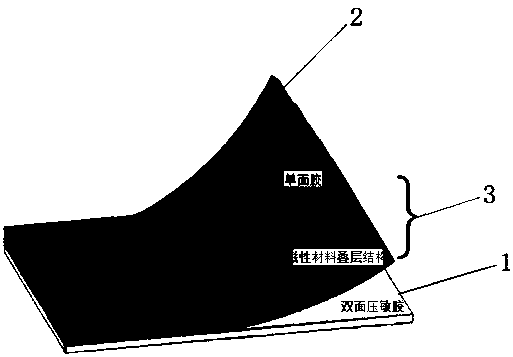

[0025] see figure 1 As shown, a composite magnetic material with high performance and high frequency response with a laminated structure is composed of a bottom layer material, an interlayer material and a top layer material sequentially stacked, wherein the bottom layer material is a layer of black or semi-black non-transparent Double-sided pressure-sensitive adhesive 1, a layer of black or sub-black single-sided adhesive 2, the interlayer material is a magnetic material laminated by alternating layers of any two or three soft magnetic materials among ferrite, nanocrystalline and amorphous layer structure3.

[0026] In the laminated structure of magnetic materials, the thickness of each layer of ferrite is 10-40 microns, the thickness of each layer of nanocrystals and amorphous is 10-30 microns, and two adjacent Layers of soft mag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com