Metal composite magnetic powder and metal magnetic powder core

A metal composite and magnetic powder core technology, applied in the field of metal composite magnetic powder and metal magnetic powder core, can solve problems such as complicated steps, and achieve the effects of short response time, high magnetic permeability and low high frequency loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation of the metal composite magnetic powder of the present invention includes: reacting the flattened metal magnetic powder with nitrogen plasma to obtain the metal composite magnetic powder with a nitride insulating coating layer formed on the surface.

[0028] During the reaction, N 2 Ionized into nitrogen ions, nitrogen ions have good activity, can quickly react with metal magnetic powder, and in situ synthesize insulating nitride on the surface of metal magnetic powder, fully ensuring the uniformity and integrity of the insulating layer. These nitrides have high strength, stability, and wear resistance, which can ensure that the metal magnetic powder core blocks the electrical contact between the metal magnetic powder during the pressing molding process and use, effectively reduces high-frequency eddy current loss, and broadens the application field of the magnetic powder core.

[0029] At present, there are two types of metal magnetic powder coating meth...

Embodiment 1

[0047] 1. Preparation of sendust magnetic powder core

[0048] (1) Put the sendust magnetic powder into a frequency conversion planetary ball mill for ball milling, use quenched steel balls, the ball-to-material ratio is 12:1, the ball mill speed is 35r / min, and the ball milling time is 40h to obtain flat sendust magnetic powder .

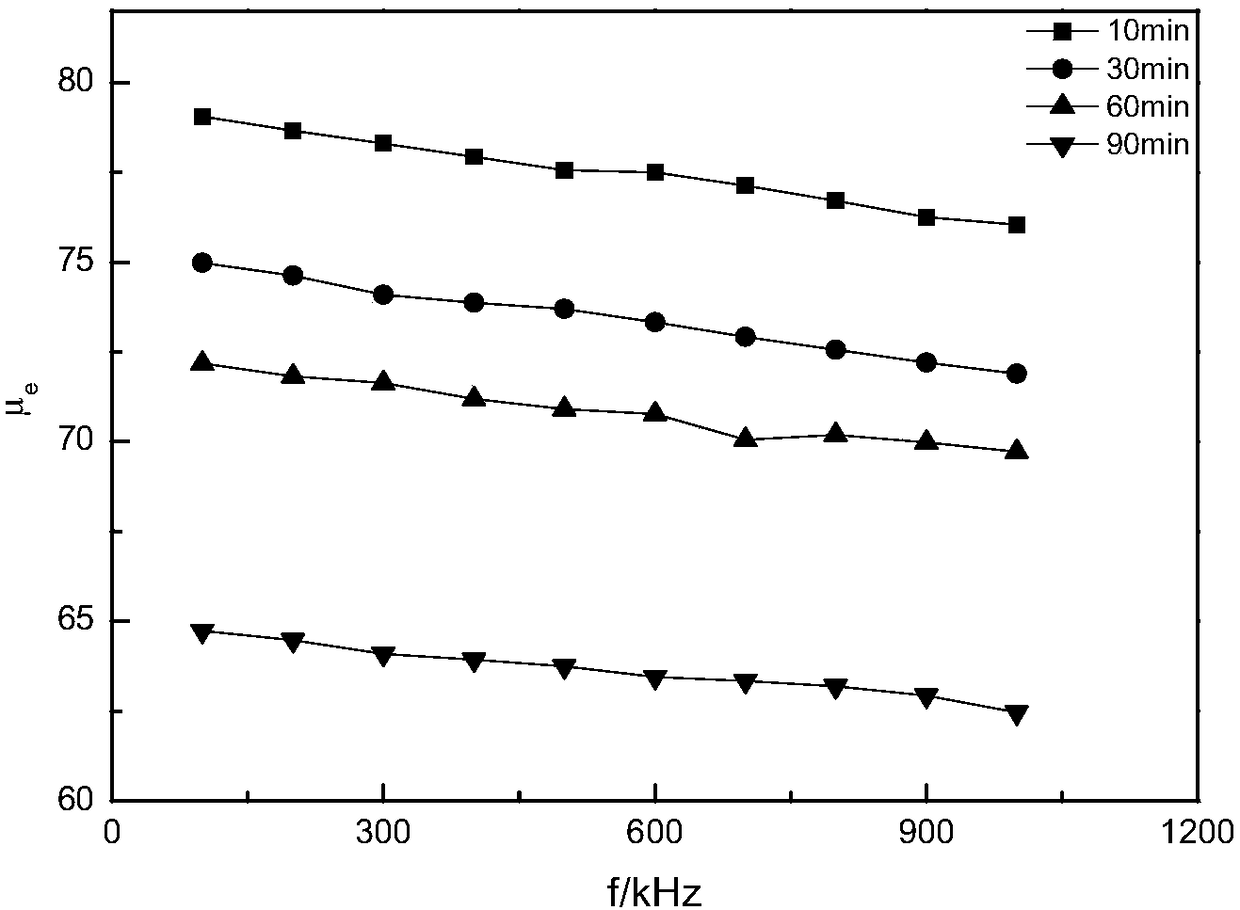

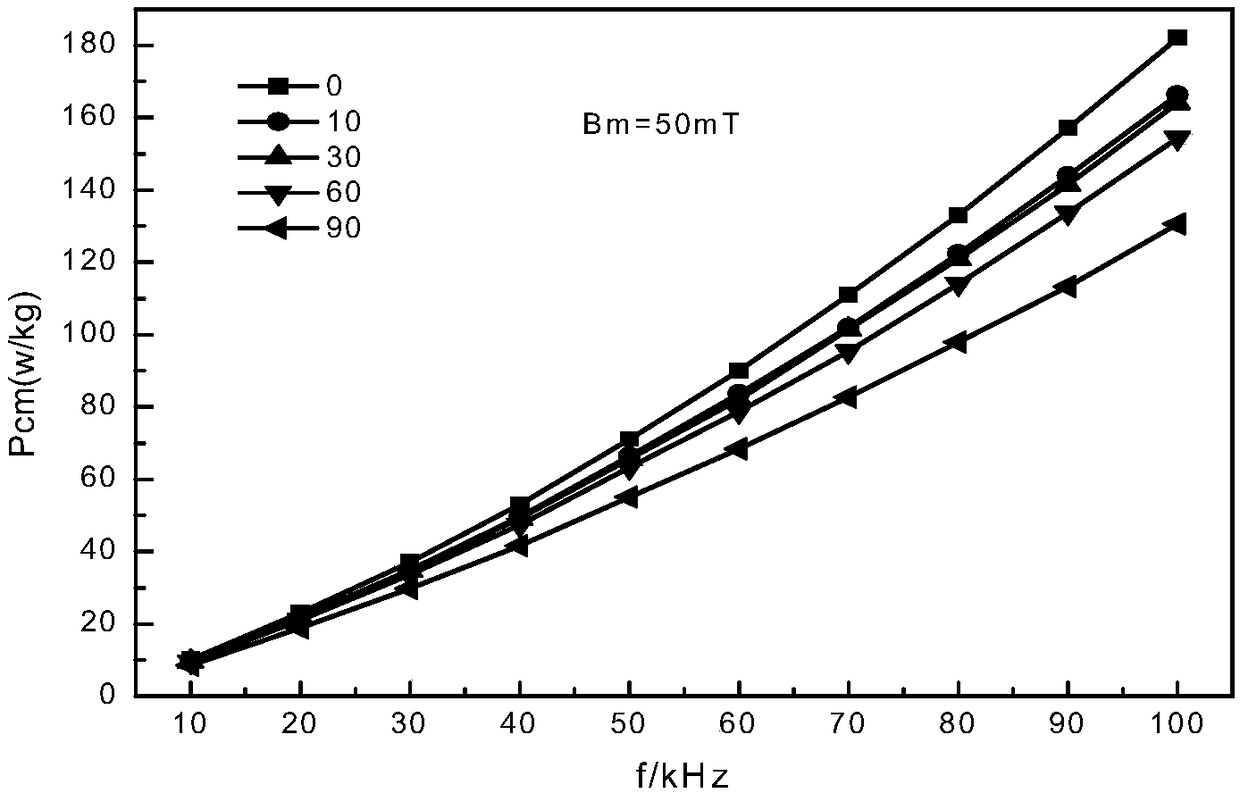

[0049] (2) Put the ball-milled sendust magnetic powder into the reaction chamber of the plasma-enhanced chemical vapor deposition equipment, evacuate to 3pa, and then pass N 2 , N 2 Keep the pressure at 30pa, start the radio frequency power supply, the radio frequency power is 200w, start the heating device of the reaction chamber, control the temperature at 300°C, and set the reaction time at 0min, 10min, 30min, 60min and 90min, and obtain 5 types of nitride insulating packages formed on the surface Coated sendust composite magnetic powder, these five kinds of sendust composite magnetic powder are numbered a 1 , b 1 、c 1 、d 1 and e 1 .

[...

Embodiment 2

[0061] 1. Preparation of sendust magnetic powder core

[0062] (1) Put the sendust magnetic powder into a frequency conversion planetary ball mill for ball milling, use quenched steel balls, the ball-to-material ratio is 12:1, the ball mill speed is 35r / min, and the ball milling time is 40h to obtain flat sendust magnetic powder .

[0063] (2) Put the ball-milled sendust magnetic powder into the reaction chamber of the plasma-enhanced chemical vapor deposition equipment, vacuumize to 3pa, and then pass into O 2 , O 2 Keep the pressure at 26pa, start the radio frequency power supply, the radio frequency power is 100w, do not start the heating device of the reaction chamber, set the reaction time to 0min, 10min, 30min, 60min and 90min, and obtain 5 kinds of iron silicon with nitride insulating coating on the surface Aluminum composite magnetic powder, these five kinds of iron-silicon-aluminum composite magnetic powder are numbered a 2 , b 2 、c 2 、d 2 and e 2 . Use VSM (v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com