Multicomponent iron-based amorphous soft magnetic alloy

A technology of iron-based amorphous and soft magnetic alloys, which is applied in the direction of magnetic materials, magnetic objects, electrical components, etc., can solve the problems of difficult industrial production and poor comprehensive performance of iron-based amorphous soft magnetic alloys, and achieve simplification of production process, Effect of low core loss and improved ability to form amorphous crystals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

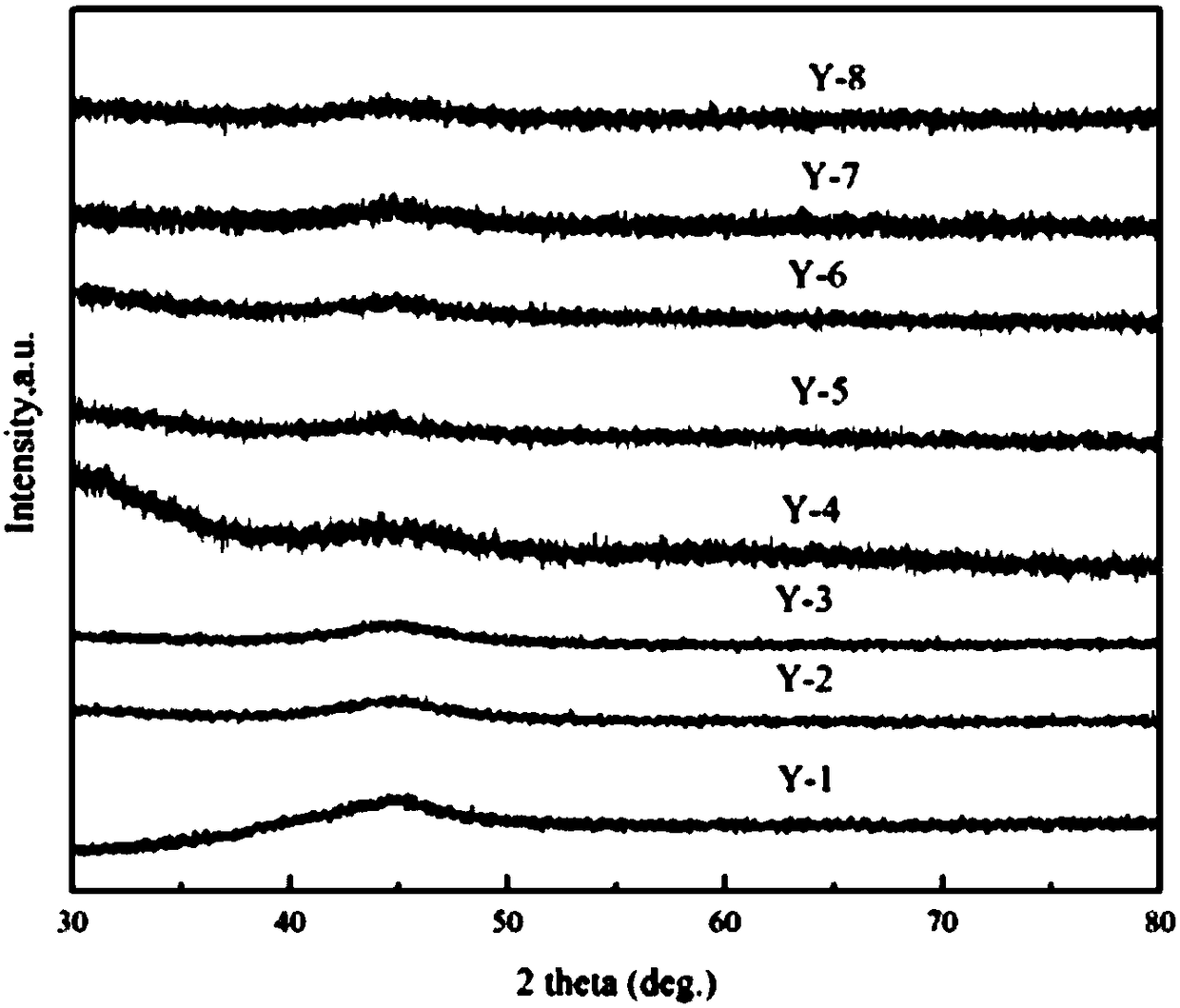

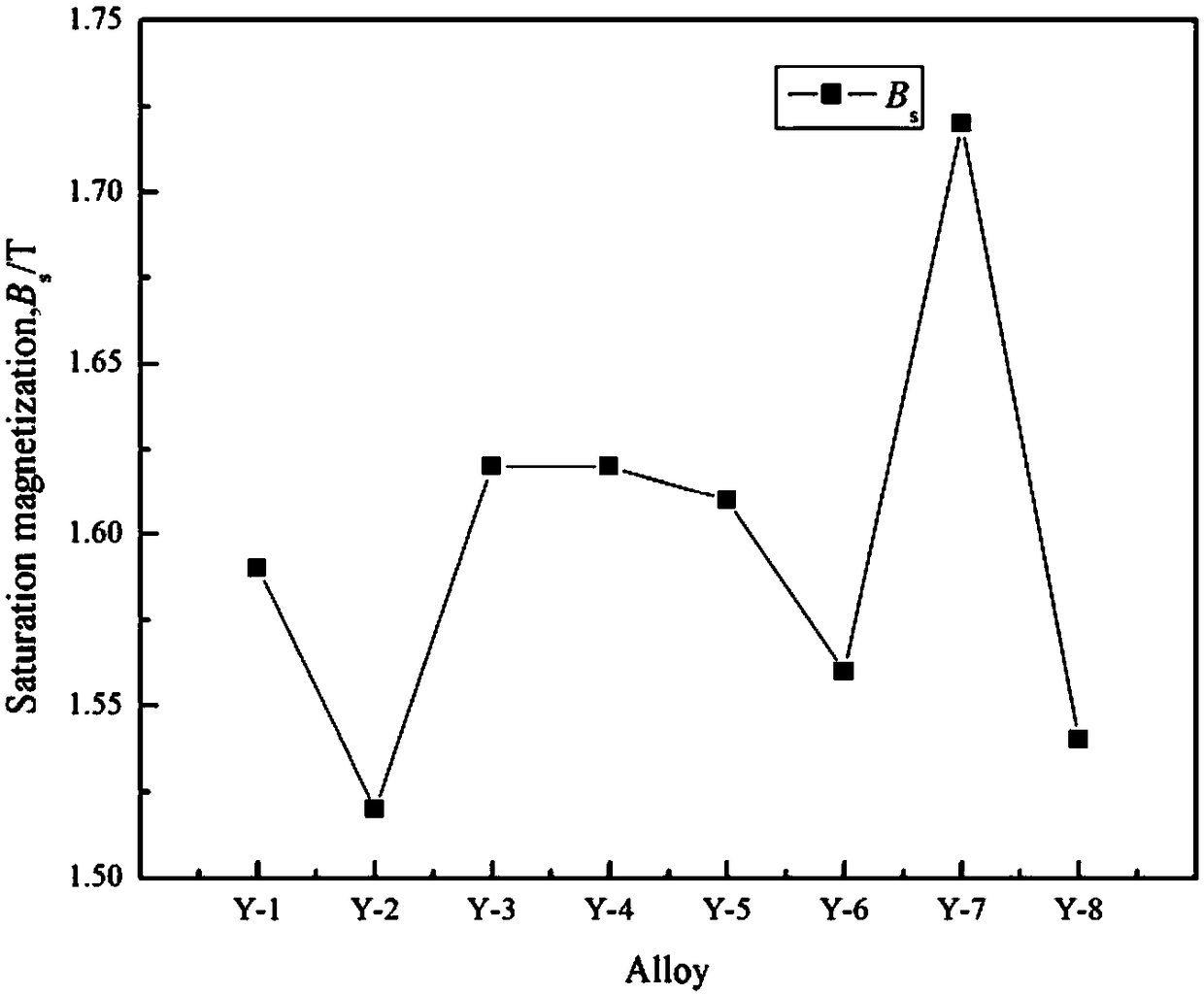

[0045] A multi-component iron-based amorphous soft magnetic alloy, the alloy expression is Fe 78.56 Si 9.17 B 11.20 P 0.11 Ni 0.92 C 0.04 , denoted as Y-1. As a more detailed example, its preparation method includes the following steps:

[0046] (1) Ingredients: Fe with a purity of 99.9wt%, Si with a purity of 99.99wt%, FeB with a B content of 17.40wt%, FeP with a P content of 24.98wt%, Ni and C with a purity of 99.99wt% For 5wt% FeC, dosing according to the above alloy expression. Before weighing the raw materials, remove impurities such as oxide films on the surface of the raw materials with sandpaper or a grinder, and then put the Fe and Ni raw materials into a beaker filled with absolute ethanol, perform ultrasonic cleaning for 250S, and then use a blower to blow them completely dry.

[0047] (2) Melting master alloy: Put the prepared master alloy raw materials into a quartz crucible, put the alloy components with high density and low melting point on it, put the q...

Embodiment 2

[0051] A multi-component iron-based amorphous soft magnetic alloy, the alloy expression is Fe 78.29 Si 8.92 B 11.25 P 0.15 Ni 0.90 C 0.49 , denoted as Y-2. As a more detailed example, its preparation method includes the following steps:

[0052] (1) Ingredients: Fe with a purity of 99.9wt%, Si with a purity of 99.99wt%, FeB with a B content of 17.40wt%, FeP with a P content of 24.98wt%, Ni and C with a purity of 99.99wt% For 5wt% FeC, dosing according to the above alloy expression. Before weighing the raw materials, remove impurities such as oxide films on the surface of the raw materials with sandpaper or a grinder, and then put the Fe and Ni raw materials into a beaker filled with absolute ethanol, perform ultrasonic cleaning for 240S, and then use a blower to blow them completely dry.

[0053] (2) Melting master alloy: Put the prepared master alloy raw materials into a quartz crucible, put the alloy components with high density and low melting point on it, put the q...

Embodiment 3

[0057] A new type of iron-based amorphous soft magnetic alloy, the alloy expression is Fe 80 Si 8.52 B 10.41 P 0.11 Ni 0.92 C 0.04 , denoted as Y-3. As a more detailed example, its preparation method includes the following steps:

[0058] (1) Ingredients: Fe with a purity of 99.9wt%, Si with a purity of 99.99wt%, FeB with a B content of 17.40wt%, FeP with a P content of 24.98wt%, Ni and C with a purity of 99.99wt% For 5wt% FeC, dosing according to the above alloy expression. Before weighing the raw materials, remove impurities such as oxide films on the surface of the raw materials with sandpaper or a grinder, and then put the Fe and Ni raw materials into a beaker filled with absolute ethanol, perform ultrasonic cleaning for 250S, and then use a blower to blow them completely dry.

[0059] (2) Melting master alloy: Put the prepared master alloy raw materials into a quartz crucible, put the alloy components with high density and low melting point on it, put the quartz c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com