Heat exchange adjusting system of coal economizer

An economizer and heat regulation technology, applied in preheating, feed water heaters, fluid heaters, etc., can solve the problem that the economizer cannot adjust the heat exchange effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

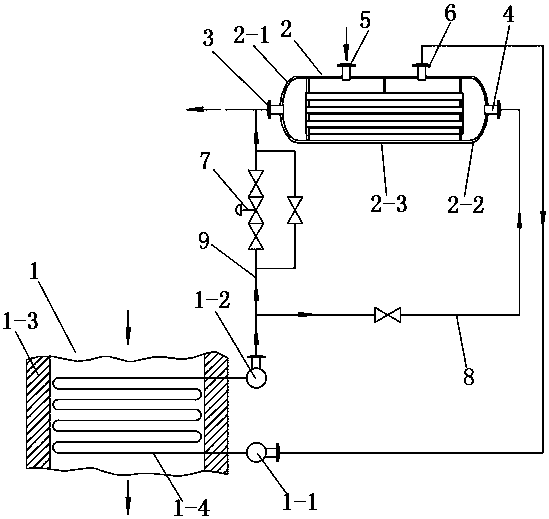

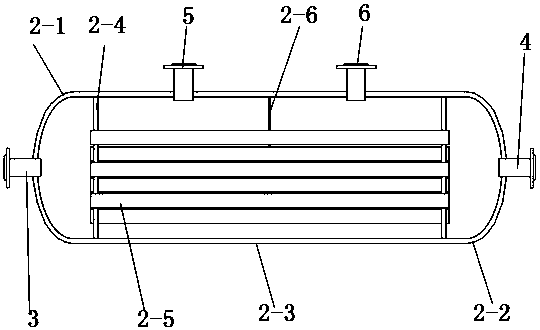

[0016] Such as figure 1 , figure 2 In the economizer heat exchange adjustment system shown, the fluid that is fed in is water, and the water is pressurized into the system through a pump, which includes an economizer 1, and the economizer is equipped with an inlet header 1-1, an outlet header Box 1-2, furnace wall 1-3, serpentine pipe 1-4 installed in furnace wall 1-3 and connected with inlet header 1-1 and outlet header 1-2, which also includes heat exchanger 2 , the heat exchanger 2 is specifically a tube-and-tube heat exchanger, which includes a front end head 2-1, a rear end head 2-2, and a middle shell 2-3, and the two heads and the shell 2-3 pass through The tube plate 2-4 is separated, the heat exchange tube 2-5 is welded on the tube plate 2-4, the hot water outlet 3 and the hot water inlet 4 are respectively arranged on the front end head 2-1 and the back end head 2-2, The cold water inlet 5 and the cold water outlet 6 are respectively arranged on the housing 2-3, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com