Alcohol ether fuel pump

A fuel pump and alcohol ether technology, which is applied to liquid fuel feeders, engine components, machines/engines, etc., can solve the problems of high price, take time to popularize, and affect the service life, so as to solve the problems of corrosion and structure. Design scientific and reasonable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

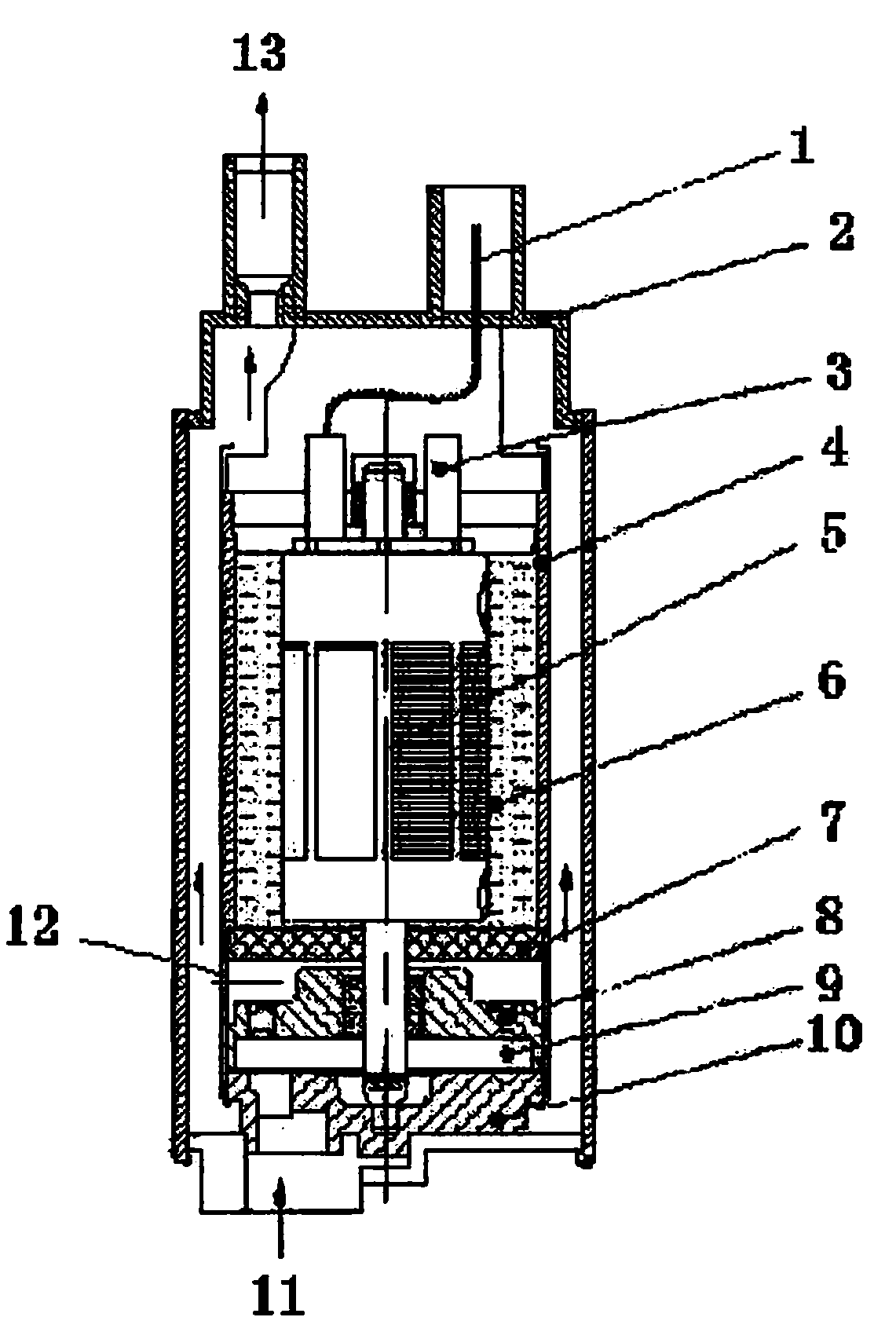

[0010] figure 1 Shown is an alcohol ether fuel pump, which includes a housing 4, a pump body and a motor in the housing 4, and a housing 2. The housing 2 is arranged outside the housing 4 and forms a jacket with the housing 4. The top of the housing 2 There is an oil outlet 13 connected with the fuel pipeline; the housing 4 is provided with a rubber pad 7, and the rubber pad 7 divides the housing 4 into two parts, the lower part is provided with a pump body, and the upper part is provided with a motor; Six through holes 12 are evenly distributed around the upper casing of the pump body, and the through holes 12 directly reach the oil outlet 13 through the jacket to form a fuel passage. The gap in the housing of the motor is set on the top of the rubber pad 7 and filled with cooling oil. The surface of the jacket between the inner shell and the outer shell, that is, the outer wall of the shell 4 and the inner wall of the outer shell 2, is coated with an alcohol-ether fuel-resi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com