Construction method of pouring asphalt sidewalk structure with double-layer colored ceramsite on steel bridge deck

A construction method and pouring technology, applied in bridges, buildings, bridge parts, etc., can solve the problems of easy breakage, poor durability and corrosion of plastic panels, and achieve the effect of simple construction method, high walking comfort, and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings.

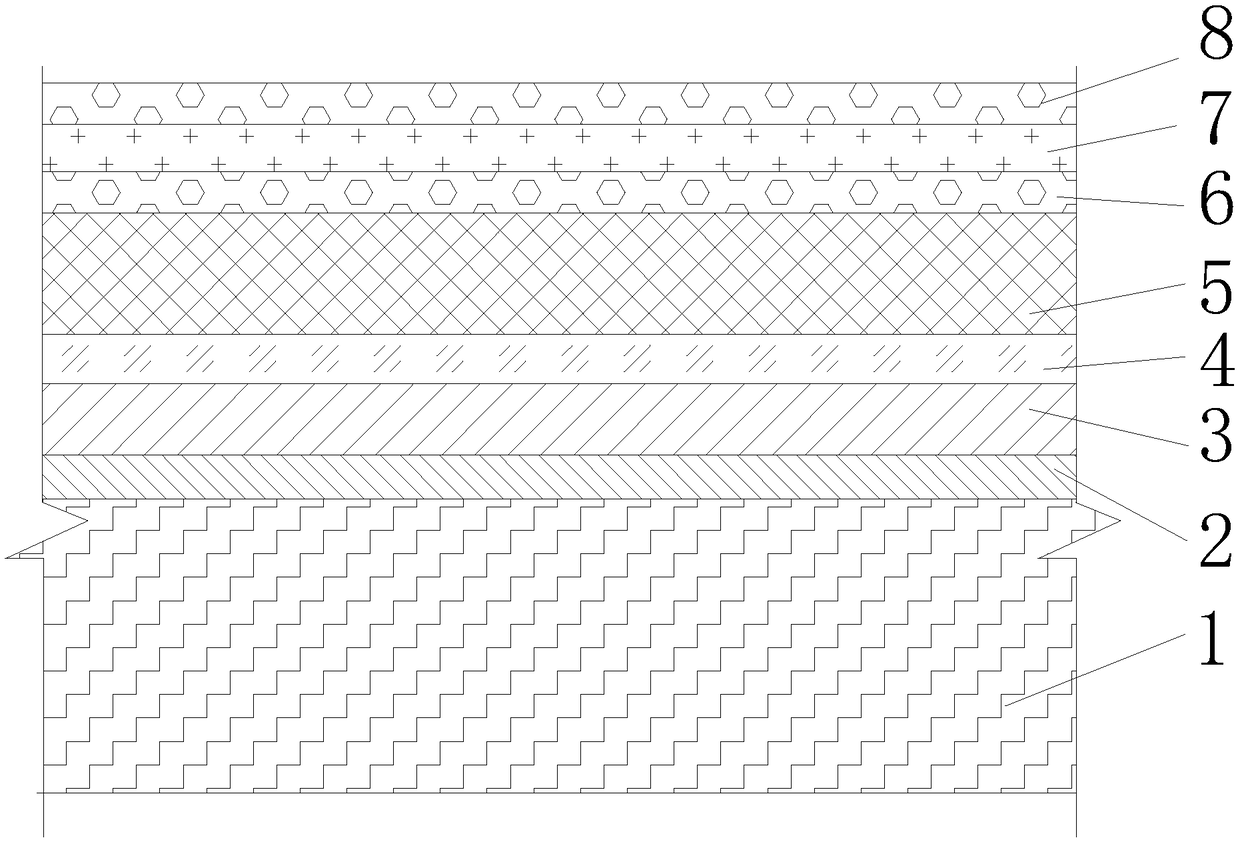

[0036] In specific implementation, such as figure 1 Shown, a kind of steel bridge deck pouring type asphalt double-layer colored ceramsite sidewalk structure construction method comprises the following steps:

[0037] 1), the steel bridge deck 1 is subjected to sandblasting and derusting treatment;

[0038] 2), paint the anti-corrosion layer 2 and the waterproof layer 3 on the steel bridge deck 1 in sequence;

[0039] 3), after the waterproof layer 3 is solidified, paint the lower adhesive layer 4 on the steel bridge deck 1 where the waterproof layer 3 is applied, and then lay the cast-type asphalt mixture layer 5;

[0040] 4), spread the first colored ceramsite layer 6 on the pouring asphalt mixture layer 5, after the spreading is completed, roll and compact, and after cooling, clean up the ceramsite not embedded in the pouring asphalt mixture layer 5;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com