Production process for outdoor cloth made from color-cloud low-stretch pongee

A spring pongee household, production process technology, applied in textiles and papermaking, textile material processing, heating/cooling fabrics, etc., can solve the problems of poor ultraviolet reflection effect, poor fabric hiding power, and poor metallic luster effect, etc. Achieve the effect of increasing the added value of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

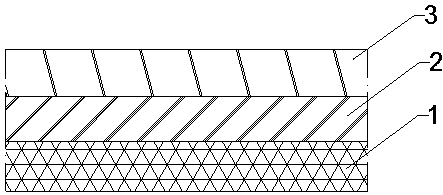

Image

Examples

Embodiment 1

[0042] Embodiment 1: a kind of colorful cloud makeup low-elastic pongee outdoor fabric production process provided by the invention comprises the following steps:

[0043] a. Seam the gray cloth;

[0044] b. Desizing and dyeing the connected gray cloth;

[0045] c. Put the dyed fabric into a sizing machine for widening; wherein, the oven temperature of the sizing machine is set at 190°C, and the oven residence time is 16s. At the same time, 38g / L of fluorocarbon water repellent is added to control the weft skew less than Within 3%; the gray cloth passes through the photoelectric automatic weft adjustment equipment when finalizing.

[0046] d. Carry out calendering finishing on the shaped and widened gray cloth; the calendering finishing operation is carried out in the calender, in which the mirror roll temperature is 205°C, the nip pressure is 110 kg / cm², and the speed is 60M / min. twice.

[0047] e. Prepare the shading bottom coating glue in proportion, wherein, fully disso...

Embodiment 2

[0054] Embodiment 2: a kind of colorful cloud makeup low-elastic pongee outdoor fabric production process provided by the invention comprises the following steps:

[0055] a. Seam the gray cloth;

[0056] b. Desizing and dyeing the connected gray cloth;

[0057] c. Put the dyed fabric into a sizing machine for widening; wherein, the oven temperature of the sizing machine is set at 210° C., and the oven residence time is 20 s. At the same time, 45 g / L of fluorocarbon water repellent is added to control the weft skew less than Within 3%; the gray cloth passes through the photoelectric automatic weft adjustment equipment when finalizing.

[0058] d. Carry out calendering finishing on the shaped and widened gray cloth; the calendering finishing operation is carried out in the calender, in which the mirror roll temperature is 210°C, the nip pressure is 120 kg / cm², and the speed is 80M / min, calendering twice.

[0059] e. Prepare the shading bottom coating glue in proportion, wher...

Embodiment 3

[0066] Embodiment 3: a kind of colorful cloud makeup low-elastic pongee outdoor fabric production process provided by the invention comprises the following steps:

[0067] a. Seam the gray cloth;

[0068] b. Desizing and dyeing the connected gray cloth;

[0069] c. Put the dyed fabric into a sizing machine for widening; wherein, the oven temperature of the sizing machine is set at 200° C., and the oven residence time is 18 s. At the same time, 41.5 g / L of fluorocarbon water repellent is added to control the weft inclination to Within 2%; the gray cloth passes through the photoelectric automatic weft adjustment equipment when finalizing.

[0070] d. Carry out calendering finishing on the shaped and widened gray cloth; the calendering finishing operation is carried out in the calender, in which the mirror roll temperature is 207.5°C, the nip pressure is 115 kg / cm², and the speed is 70M / min. twice.

[0071] e. Prepare the shading bottom coating glue in proportion, wherein, ful...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com