Autoclaved aerated concrete block and preparation method thereof

A concrete block and autoclaved aeration technology, which is applied to ceramic products, other household appliances, applications, etc., can solve the problem of poor air-entraining effect of aerated concrete, great influence of bubble retention time, and misalignment of slurry thickening degree. and other problems, to achieve the effect of improving the foaming effect, light weight and increasing wind load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

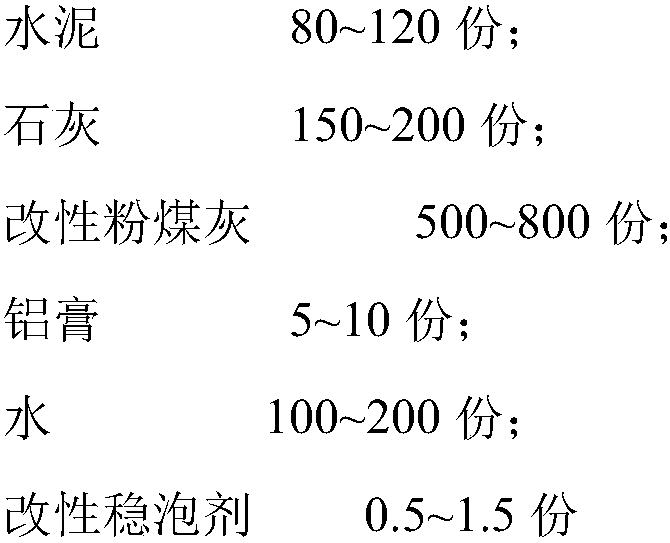

[0064] Embodiment 1: (1) Preparation of slurry: in parts by weight, take 500 parts of modified fly ash and 50 parts of water, add water in stages to the modified fly ash, and carry out primary pulping, pulping The final mixture undergoes two-stage stirring and three-stage stirring, and the slurry is obtained after being fully mixed;

[0065] (2) Preparation of dry material: in parts by weight, take 80 parts of cement and 150 parts of quicklime, and fully stir to obtain dry material;

[0066] (3) Preparation of aluminum paste: in parts by weight, take 5 parts of aluminum powder paste, feed and stir, and fully mix the scaly aluminum powder paste into an aluminum paste with uniform texture;

[0067] (4) Ingredients: Take the slurry, dry material and aluminum paste prepared in steps 1, 2, and 3, by weight, and then take 50 parts of water, mix and pour, add 0.5% modified foam stabilizer while stirring Stirring is carried out at 45°C, and the stirring time is not less than 15 minut...

Embodiment 2

[0071] Embodiment 2: (1) Preparation of slurry: in parts by weight, take 800 parts of modified fly ash and 100 parts of water, add water in stages to the modified fly ash, and carry out primary pulping, pulping The final mixture undergoes two-stage stirring and three-stage stirring, and the slurry is obtained after being fully mixed;

[0072] (2) Preparation of dry material: in parts by weight, take 120 parts of cement and 200 parts of quicklime, and fully stir to obtain dry material;

[0073] (3) Prepare aluminum paste: in parts by weight, take 10 parts of aluminum powder paste, feed and stir, and fully mix the scaly aluminum powder paste into an aluminum paste with uniform texture;

[0074] (4) Ingredients: Take the slurry, dry material and aluminum paste prepared in steps 1, 2 and 3, by weight, and then take 100 parts of water, mix and pour, add modified foam stabilizer 1.5 while stirring Stirring is carried out under the condition of 45°C, and the stirring time is not les...

Embodiment 3

[0078] Embodiment 3: (1) Preparation of slurry: in parts by weight, take 650 parts of modified fly ash and 75 parts of water, add water in stages to the modified fly ash, and carry out primary pulping, pulping The final mixture undergoes two-stage stirring and three-stage stirring, and the slurry is obtained after being fully mixed;

[0079] (2) Preparation of dry material: in parts by weight, take 100 parts of cement and 175 parts of quicklime, and fully stir to obtain dry material;

[0080] (3) Preparation of aluminum paste: in parts by weight, take 8 parts of aluminum powder paste, feed and stir, fully mix the scaly aluminum powder paste into an aluminum paste with uniform texture;

[0081] (4) Ingredients: take the slurry, dry material and aluminum paste prepared in steps 1, 2 and 3, by weight, and then take 75 parts of water, mix and pour, add modified foam stabilizer 1 while stirring Stirring is carried out under the condition of 45°C, and the stirring time is not less ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com