Closed-loop operation control method for nano-scale component under SEM and design scheme for operation platform

A technology of nano-manipulation and operation platform, which is applied in the fields of nano-structure manipulation, nano-structure manufacturing, nano-technology, etc., can solve the problems of easy damage, high manufacturing cost, and difficulty in making force sensors, so as to improve the perception ability, improve the control accuracy and Reliability, the effect of shortening the research cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

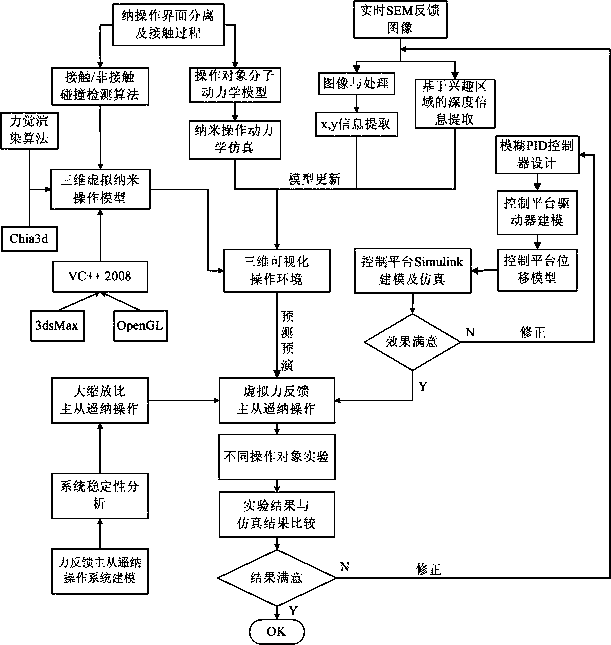

[0022] The closed-loop control method and operating platform for nano-components under SEM use molecular dynamics to simulate the operation process of nano-components, establish the best matching relationship between operating angle, operating point and single-step displacement, and theoretically solve the problem of nano-component movement, The efficiency and success rate of positioning and picking.

[0023] Analyze and find the physical characteristics and experimental parameters of the components, and establish the model of the nano-components in Lammps; through the setting of the mechanical parameters, analyze the elasticity, plasticity, and fracture characteristics of the nano-components, and analyze the nano-component models from different operating angles and operating points Carry out the operation, observe and analyze its influence on the performance of the component, and provide a theoretical basis for the research on the influence of the adhesion force in the process...

Embodiment 2

[0026] The described extraction method based on the three-dimensional feature information of the two-dimensional SEM image utilizes the ambiguity evaluation function of the region of interest of the two-dimensional SEM image to obtain the target depth information, and establishes the fuzzy PID control model of the end effector based on Simulink for simulation, and finally The obtained information is used to realize the three-dimensional closed-loop nano-operation control based on fuzzy PID; the only two-dimensional image is transformed into a three-dimensional visualized nano-operation environment, which improves the perception ability of the operator.

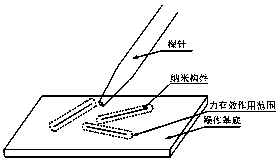

[0027] Accurately obtaining the location information of operating tools (probes) is critical for both the direct operation of the slave sample and the reconstruction of the virtual environment. Since there is no additional measuring device or sensor installed in the sample chamber of the slave SEM, the real-time two-dimensional...

Embodiment 3

[0031] In the modeling method of the described virtual nano operating environment, the model of the nano component is established in Lammps; according to the extracted three-dimensional feature information, with the help of VR technology, with VS 2008 as the main development environment, 3dsMax and OpenGL are used for joint modeling, Quickly create dynamic skeletal models of probes and components.

[0032] Based on the contact mechanism model of nano-component operation, the contact collision and non-contact collision detection algorithm of virtual nano-operation is studied, which is divided into three parts: probe and operation substrate, nanowire and operation substrate, and probe and nanowire. Do your research, then integrate.

[0033] Further study the force sense rendering algorithm, and use the Chia3d force sense rendering engine to render under the premise that the force sense rendering algorithm is verified by Matlab.

[0034] For the construction of the operation pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com