Automotive seat framework widely adapting aluminum alloy castings

A car seat frame and aluminum alloy casting technology, applied in the direction of the seat frame, etc., can solve the problems of rising mold costs, weight reduction, and difficulty in effectively reducing the weight of the seat, so as to improve the structural strength and impact resistance, and the structure is simple Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

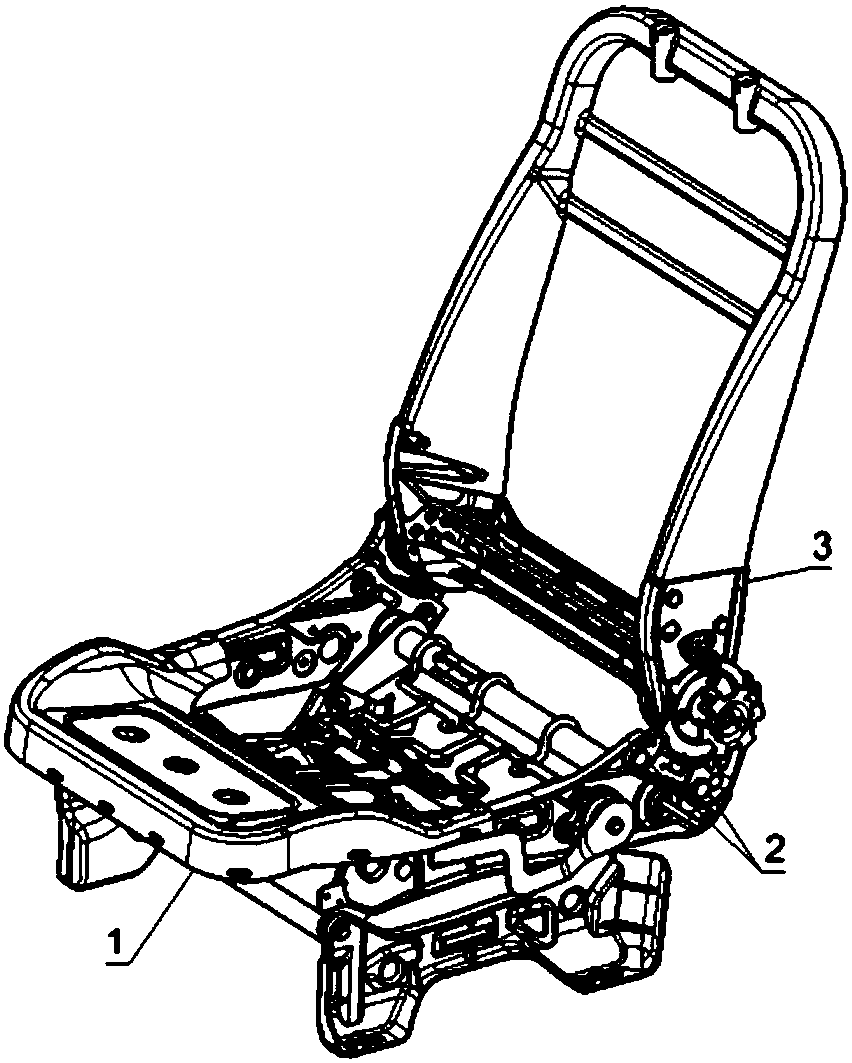

[0024] Such as figure 1 Shown: an automobile seat frame widely used in aluminum alloy castings, including a seat cushion assembly 1 and a backrest assembly 3 interconnected by backrest bolts 2 .

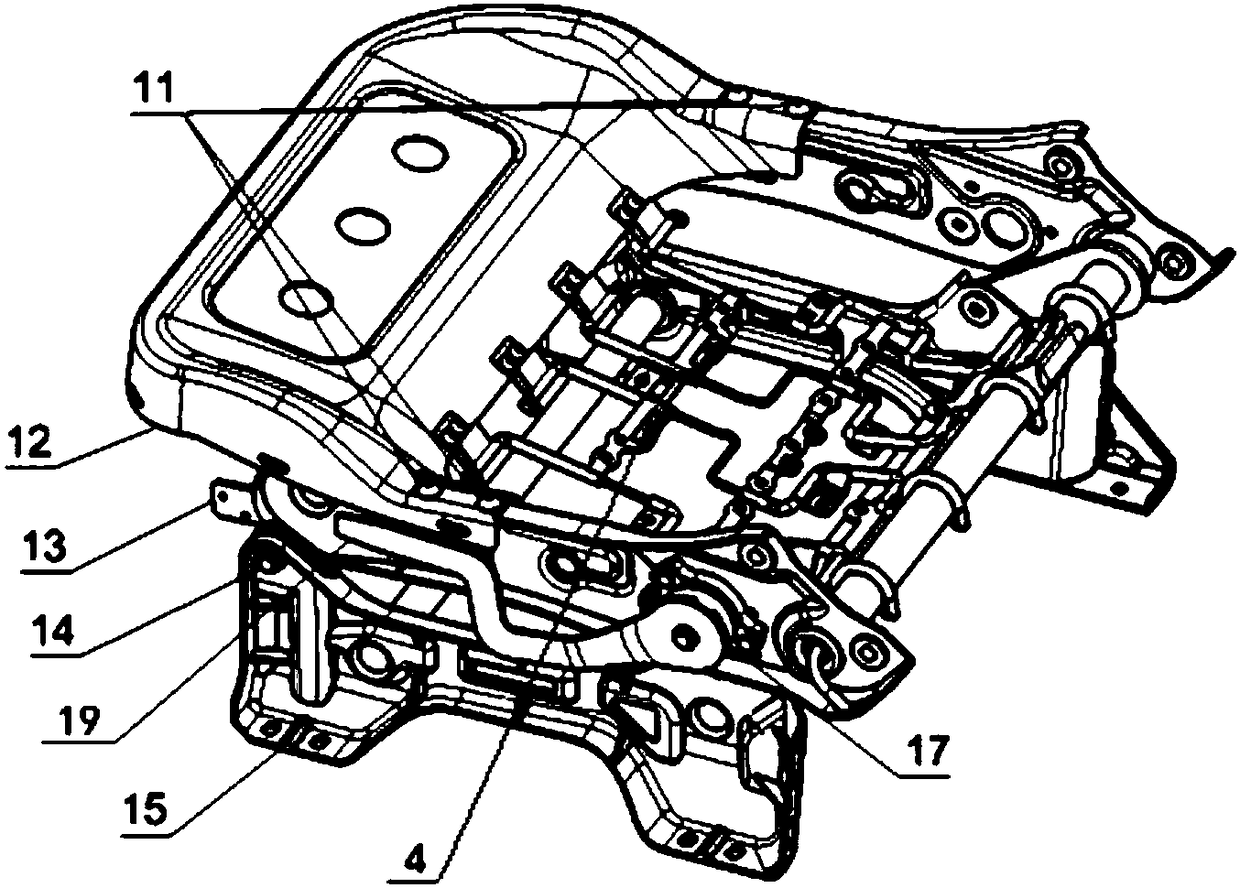

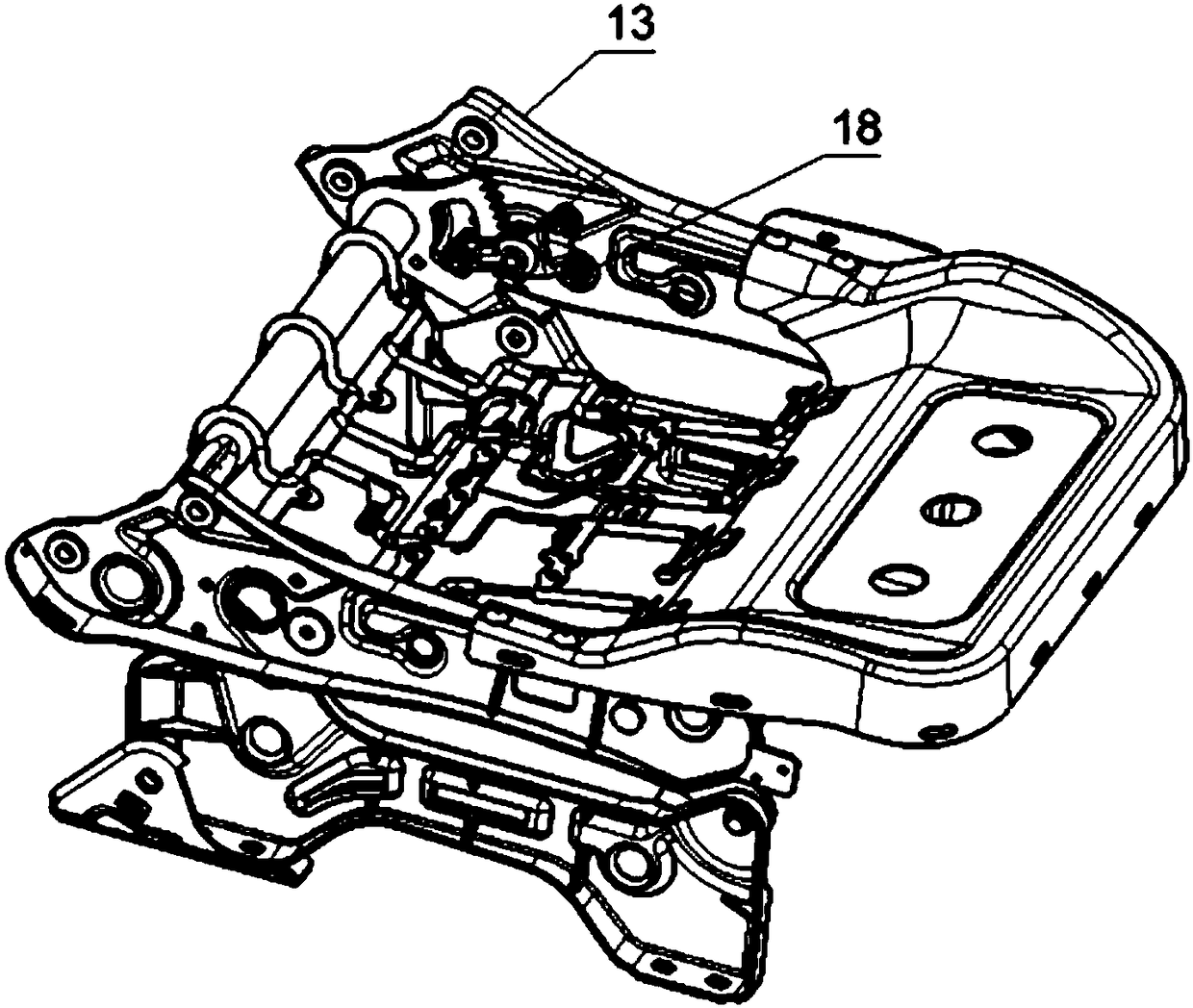

[0025] Such as figure 2 , 3 As shown: the seat cushion assembly 1 includes an upper seat frame assembly 13 and a lower seat frame assembly 15 installed up and down by using step bolts 14, and the seat pan assembly 12 is installed on the upper seat frame assembly 13 through the first rivet 11 , The riser 17 and the riser handle 19 are installed on one side of the seat frame assembly 13 by using the riser handle bolts. A spring support 4 is provided between the seat pan assembly 12 and the upper seat frame assembly 13 to fix the spring and prevent it from shifting. For the safety and stability of the structure, the inner side of the riser 17 installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com