Staggering type laser engraving device for double-pattern carpet processing

A laser engraving and staggered technology, used in laser welding equipment, metal processing equipment, welding equipment, etc., can solve the problems of inconvenient operation and use, labor-intensive operation, etc., and achieve the effect of saving time and labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

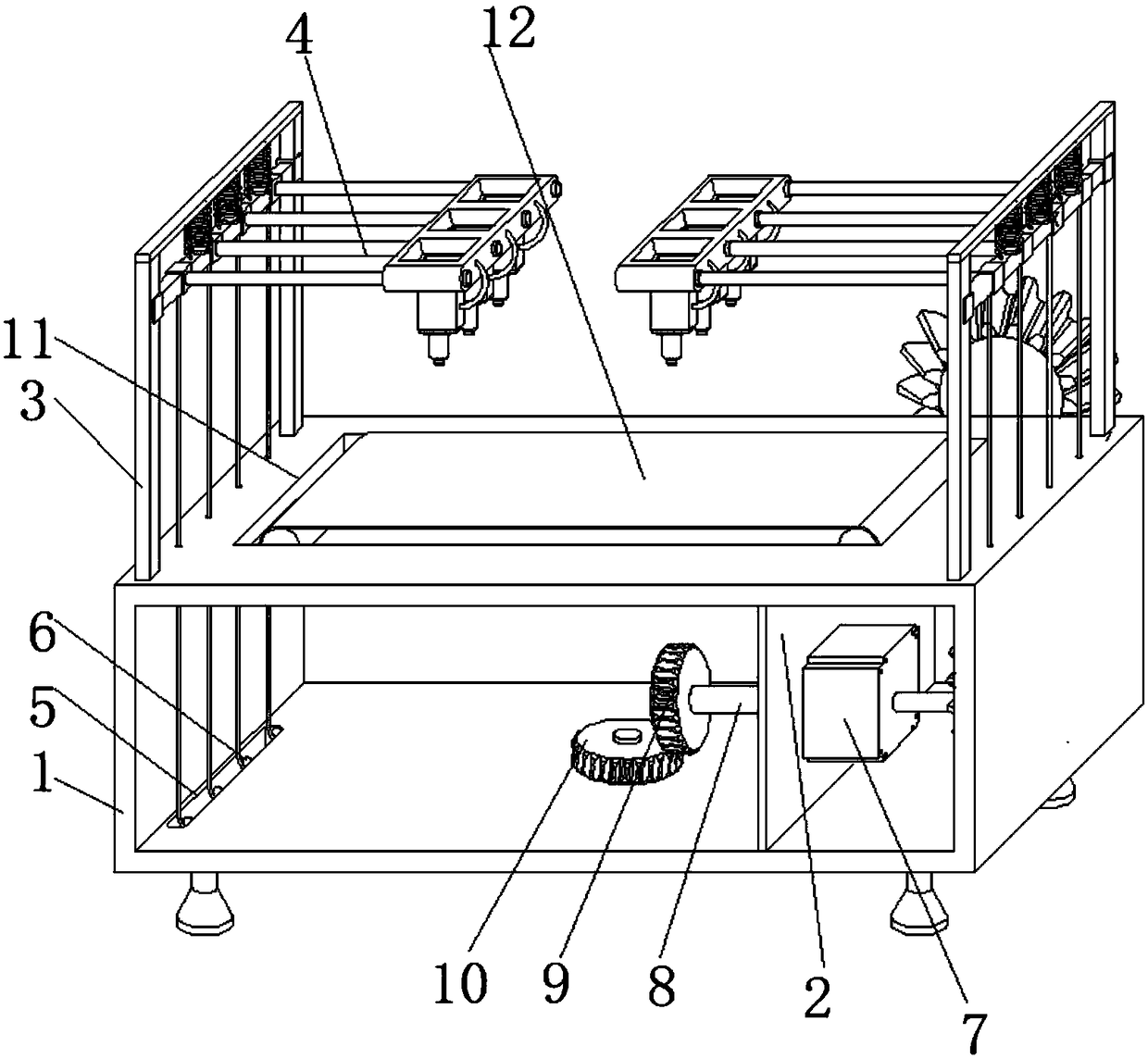

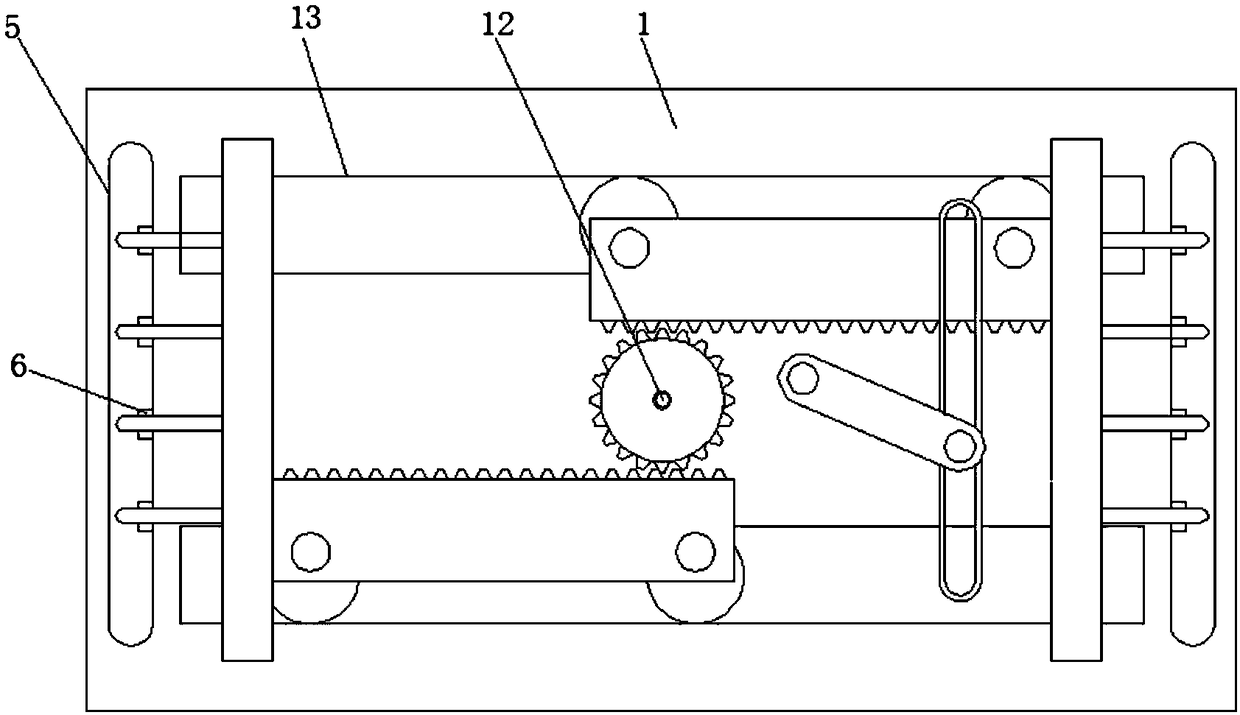

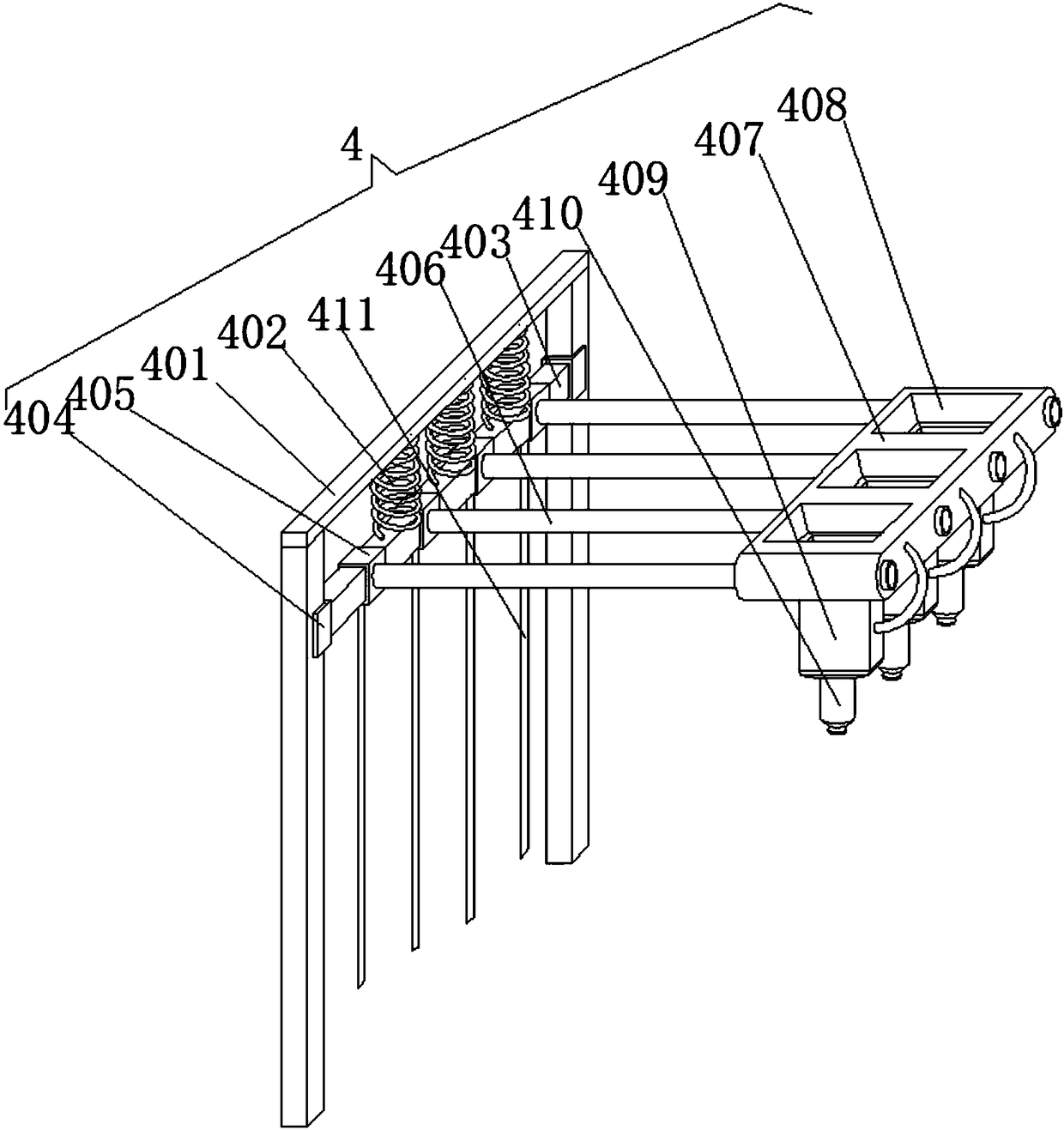

[0041] like Figure 1-2 As shown, a kind of staggered laser engraving equipment for double-pattern carpet processing includes a back-shaped work plate 1, a partition 2 is fixedly connected between the top and bottom of the back-shaped work plate 1 inner wall, and the top of the back-shaped work plate 1 The four corners are fixedly connected with vertical rods 3, and an elastic force multi-position mechanism 4 is arranged between the vertical rods 3 on both sides. The left and right sides of the inner wall bottom of the return-shaped working plate 1 are all provided with deep arc-shaped through grooves 5. The side close to the deep arc-shaped through groove 5 is fixedly connected with a guide wheel 6. By setting the guide wheel 6, the thin steel wire rope 411 will not polish the deep arc-shaped through groove 5 and the return-shaped working plate 1, and will not The thin wire rope 411 of the workpiece is repeatedly used for damage. The right side of the partition plate 2 is pro...

Embodiment 2

[0043] like Figure 1-3 As shown, a kind of staggered laser engraving equipment for double-pattern carpet processing includes a back-shaped work plate 1, a partition 2 is fixedly connected between the top and bottom of the back-shaped work plate 1 inner wall, and the top of the back-shaped work plate 1 The four corners are fixedly connected with vertical rods 3, and an elastic force multi-position mechanism 4 is arranged between the vertical rods 3 on both sides. The left and right sides of the inner wall bottom of the return-shaped working plate 1 are all provided with deep arc-shaped through grooves 5. The side close to the deep arc-shaped through groove 5 is fixedly connected with a guide wheel 6. By setting the guide wheel 6, the thin steel wire rope 411 will not polish the deep arc-shaped through groove 5 and the return-shaped working plate 1, and will not The thin wire rope 411 of the workpiece is repeatedly used for damage. The right side of the partition plate 2 is pro...

Embodiment 3

[0046] like Figure 1-5 As shown, a kind of staggered laser engraving equipment for double-pattern carpet processing includes a back-shaped work plate 1, a partition 2 is fixedly connected between the top and bottom of the back-shaped work plate 1 inner wall, and the top of the back-shaped work plate 1 The four corners are fixedly connected with vertical rods 3, and an elastic force multi-position mechanism 4 is arranged between the vertical rods 3 on both sides. The left and right sides of the inner wall bottom of the return-shaped working plate 1 are all provided with deep arc-shaped through grooves 5. The side close to the deep arc-shaped through groove 5 is fixedly connected with a guide wheel 6. By setting the guide wheel 6, the thin steel wire rope 411 will not polish the deep arc-shaped through groove 5 and the return-shaped working plate 1, and will not The thin wire rope 411 of the workpiece is repeatedly used for damage. The right side of the partition plate 2 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com