Rice cake making machine

A technology for making machines and rice cakes, which is applied in mixers, mixers with rotary stirring devices, dissolving and other directions, and can solve the problem that steamed powder cannot quickly enter the molding pipeline.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to deepen the understanding of the present invention, the present invention will be described in further detail below in conjunction with embodiments. The present embodiments are only used to explain the present invention and do not constitute a limitation on the protection scope of the present invention.

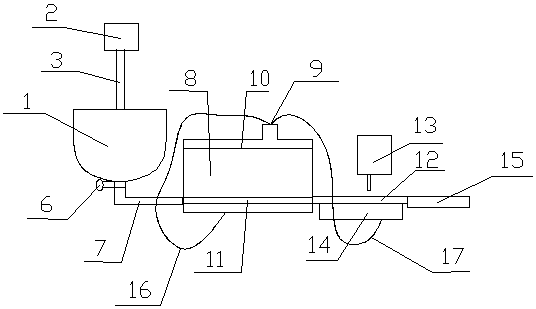

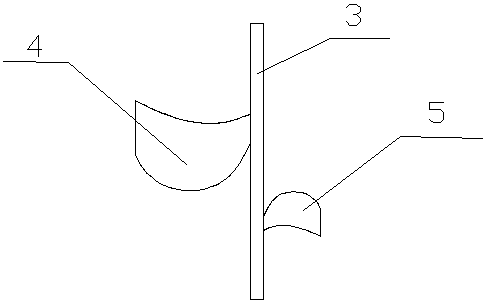

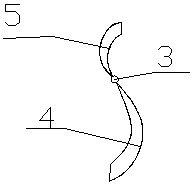

[0014] Such as Figure 1-4 As shown, this embodiment provides a rice cake making machine, including an inlet 1, the inlet 1 is in the shape of a tulip cup, a stirring drive 2 is provided above the inlet 1, and the stirring drive 2 The bottom is connected with a stirring rod 3, the upper half of the stirring rod 3 is provided with a stirring device upper blade 4, the lower half of the stirring rod 3 is provided with a stirring device lower blade 5, and the lower end of the inlet 1 is provided with a rotary valve 6 , The inlet 1 is provided with a forming pipe 7 on the right, and the forming pipe 7 is connected to the inlet 1 through a rotary valve 6. When the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com