Fruit preservative containing corn straw pyroligneous acid and application thereof

A technology of corn stalks and wood vinegar, which is applied in the field of food

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This example illustrates the preparation method of corn stalk wood vinegar.

[0028] Use corn stalks as raw materials, cut into small pieces of 2-3cm, weigh a certain amount of corn stalks each time in the carbonization furnace, and control the combustion temperature through the temperature control system of the carbonization furnace. Collect the wood vinegar when it appears, and obtain the crude wood crude liquid.

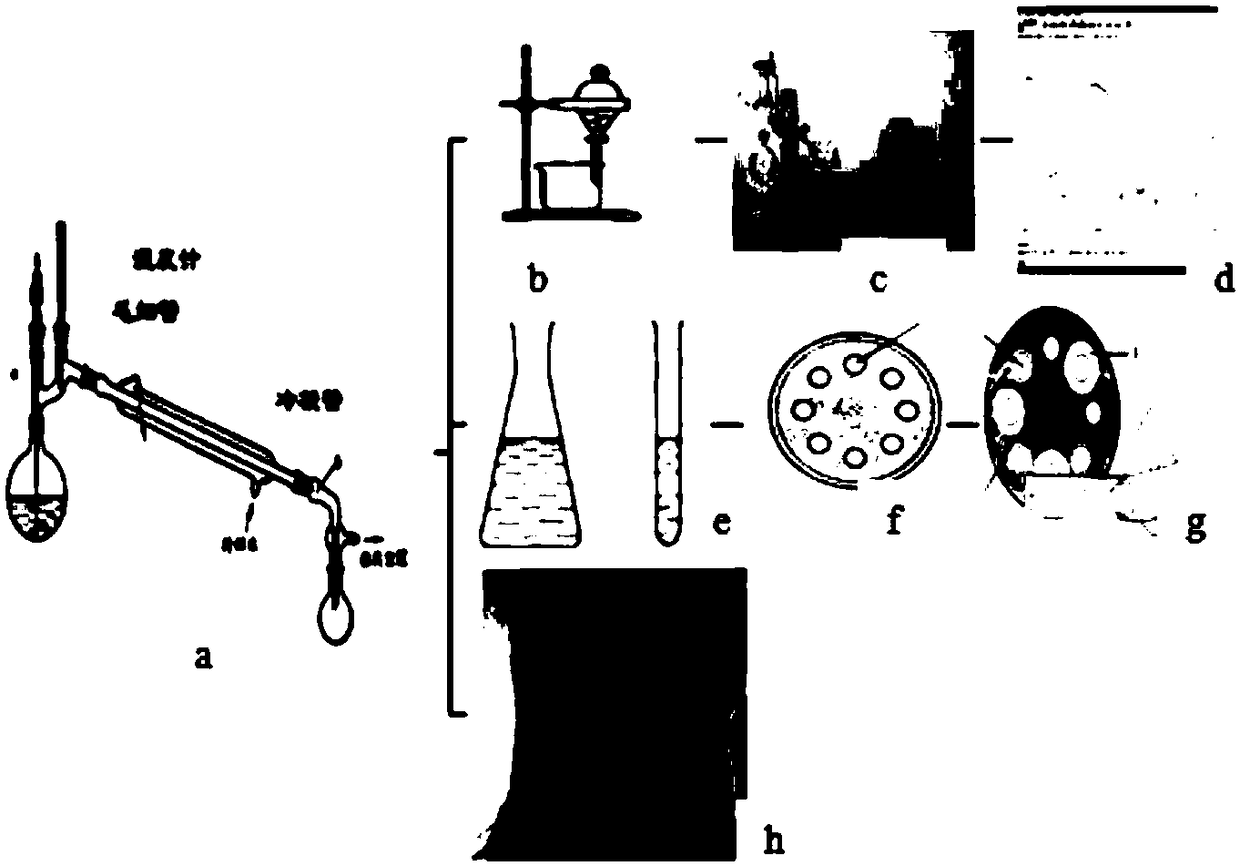

[0029] Take the crude wood vinegar liquid in a round bottom flask, install a pressurized distillation device, and start collecting the distillate at 98-103°C when the temperature rises to 98°C, which is the first vacuum distillation distillate, and transfer the above liquid into the round bottom flask , Operate as above, and carry out the second vacuum distillation to obtain refined wood vinegar.

Embodiment 2

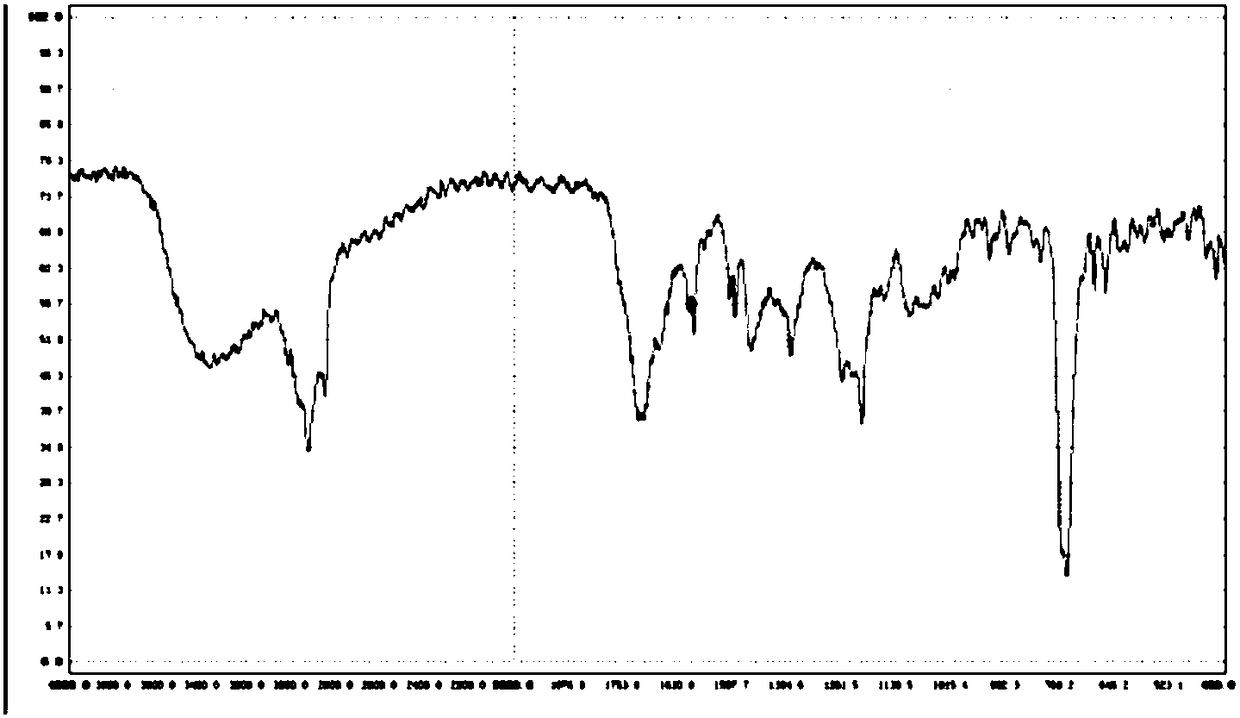

[0032] Take 100g of refined wood vinegar, extract 6 times with 30mL ether each time, combine the ether extracts, and recover the ether through a rotary evaporator to obtain dehydrated wood vinegar, which is used as an infrared spectrophotometer to analyze samples.

[0033] The conditions of the infrared spectrophotometer are: wave number range: 4000-400cm-1. Wavenumber accuracy: ≤±4cm-1(4000-2000cm-1); ≤±2cm-1(2000-400cm-1). Resolution ability: 1.5cm-1 (near 1000cm-1). Transmittance accuracy: ±0.2% T not included (noise level). Io line straightness: ≤±2%T. Stray light: ≤0.5%T(4000-650cm-1); test mode: transmittance. Scan Speed: Normal Slit Program: Normal. Response: OK. Working mode: fixed wavelength scanning.

[0034] The result is as figure 2 As shown, it can be seen from the infrared analysis chart that the blunt peak near 3400cm-1 is the characteristic absorption peak produced by OH, the double peak at 2800-3000cm-1 is the characteristic absorption peak produced by...

Embodiment 3

[0036] This example illustrates the antibacterial experiment of corn stalk wood vinegar.

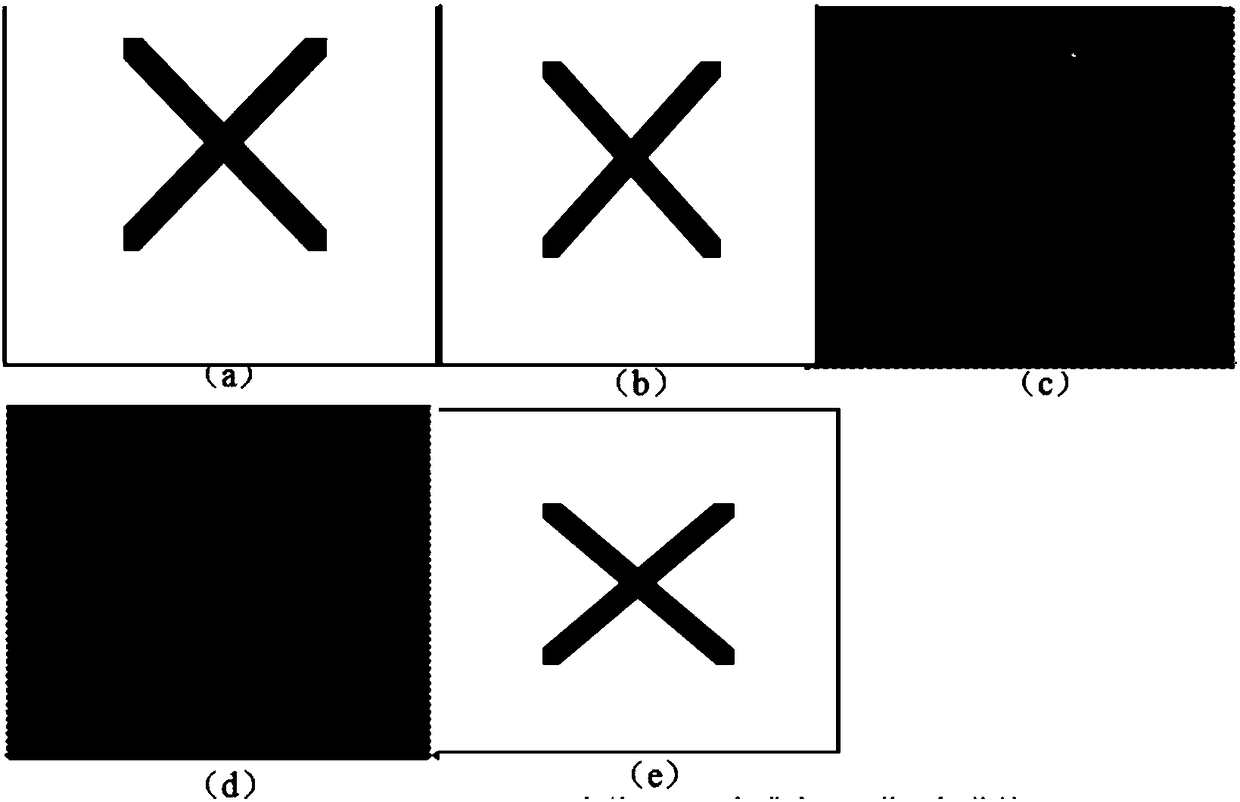

[0037] The Oxford cup method was used to carry out the bacteriostatic test on Shigella, Salmonella, Listeria monocytogenes and Staphylococcus aureus and three molds of Penicillium, Trichoderma viridans and Trichoderma reesei. Heat the sterilized PDA agar medium until it completely melts, pour it into petri dishes, 20ml per dish, and wait for it to solidify. Spread 1mL of bacterial suspension or spore suspension evenly on the surface of the culture medium with a sterile applicator. Place an Oxford cup (a round tube with an inner diameter of 6 mm, an outer diameter of 8 mm, and a height of 10 mm) directly and vertically on the surface of the culture medium, pressurize gently to make it contact with the culture medium without gaps, and add 200 microliters into the cup with a pipette gun. Raise the sample to be tested (refined wood vinegar or sterilized water), and keep it from overflowing....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com