Preparation methods of 2D nanometer titanium disulfide and 2D nanometer titanium disulfide film electrode

A two-dimensional nano, titanium disulfide technology, applied in the field of electrochemistry, can solve the problems of high electrode manufacturing cost and expensive platinum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Preparation of two-dimensional nano-TiS2:

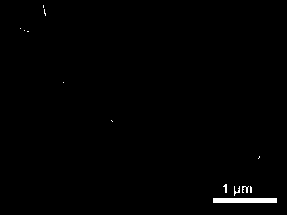

[0019] Weigh 4 g of thiourea, 50 mL of toluene, and 1 mL of titanium tetrachloride, put them into a polytetrafluoroethylene autoclave with a volume of 100 mL, and seal; place the sealed polytetrafluoroethylene autoclave in an oven at 200 °C Keep the constant temperature for 6 hours; then turn off the heating power of the oven, open the oven door, let the temperature of the autoclave drop to normal temperature naturally, and repeatedly centrifuge and wash the black precipitate in the obtained autoclave three times with methanol, and the obtained black precipitate is a two-dimensional nanometer Titanium disulfide, and the obtained black precipitate is dispersed with methanol to obtain black ultra-thin two-dimensional nano-titanium disulfide (such as figure 1 As shown, the nano-titanium disulfide flakes have a diameter of about 1-2 microns) (the average thickness is less than 20 nanometers, and the average diameter is less than 2...

Embodiment 2

[0024] Preparation of two-dimensional nano-TiS2 flexible tape-based electrodes:

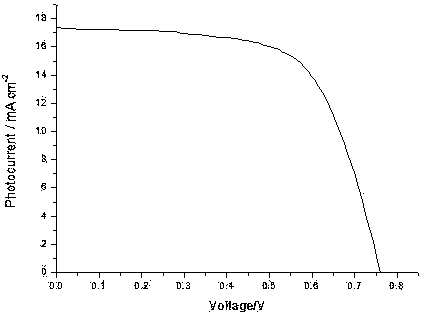

[0025] The methanol slurry (concentration is 10g / L) of the ultra-thin two-dimensional nano-titanium disulfide prepared according to Example 1 is coated on the glass surface, and a layer of uniform thickness of nano-TiS2 film (about 20 microns in thickness, square A two-dimensional nano-titanium disulfide conductive film material with a resistance of about 15 ohms); stick the adhesive layer side of the flexible transparent tape on the surface of the dry nano-TiS2 film, and the nano-TiS2 film will transfer to the surface of the tape after the tape is removed, that is A two-dimensional nano-TiS2 film with a thickness of about 30 microns is adhered on the surface of the tape, which is a bendable and flexible nano-TiS2 electrode.

[0026] Through the above method, a bendable flexible nano-TiS2 electrode with a thickness of about 30 microns and a surface sheet resistance of about 15 ohms can be obtaine...

Embodiment 3

[0028] The preparation method of the two-dimensional nano-TiS2 thin film electrode prepared by in-situ growth method is: immerse the clean FTO conductive glass substrate in saturated thiourea aqueous solution, and deposit a layer of thiourea (thickness about 20 microns) on the surface of the substrate by pulling method. , after drying in a drying oven, put it into a 100 ml polytetrafluoroethylene autoclave, which contains 500 ml of toluene solvent and 2 ml of titanium tetrachloride), seal it and put it in an oven, and react at a temperature of 200 ° C 8 hours. After the reaction is completed, cool and wash to obtain a two-dimensional nano-TiS2 thin film electrode prepared by the in-situ growth method (such as Figure 4 As shown, the diameter of each flake is about 1 micron, and the obtained two-dimensional nano-TiS2 flakes are closely connected together, and the thickness of each flake is about 20-30 nanometers,). The thickness of TiS2 in the electrode prepared by the method ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com