Multi-objective optimized overall workshop layout method based on multi-population genetic algorithm

A multi-objective optimization and genetic algorithm technology, applied in the field of multi-objective optimization of the overall layout of the workshop, can solve problems such as large impact on results and low practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

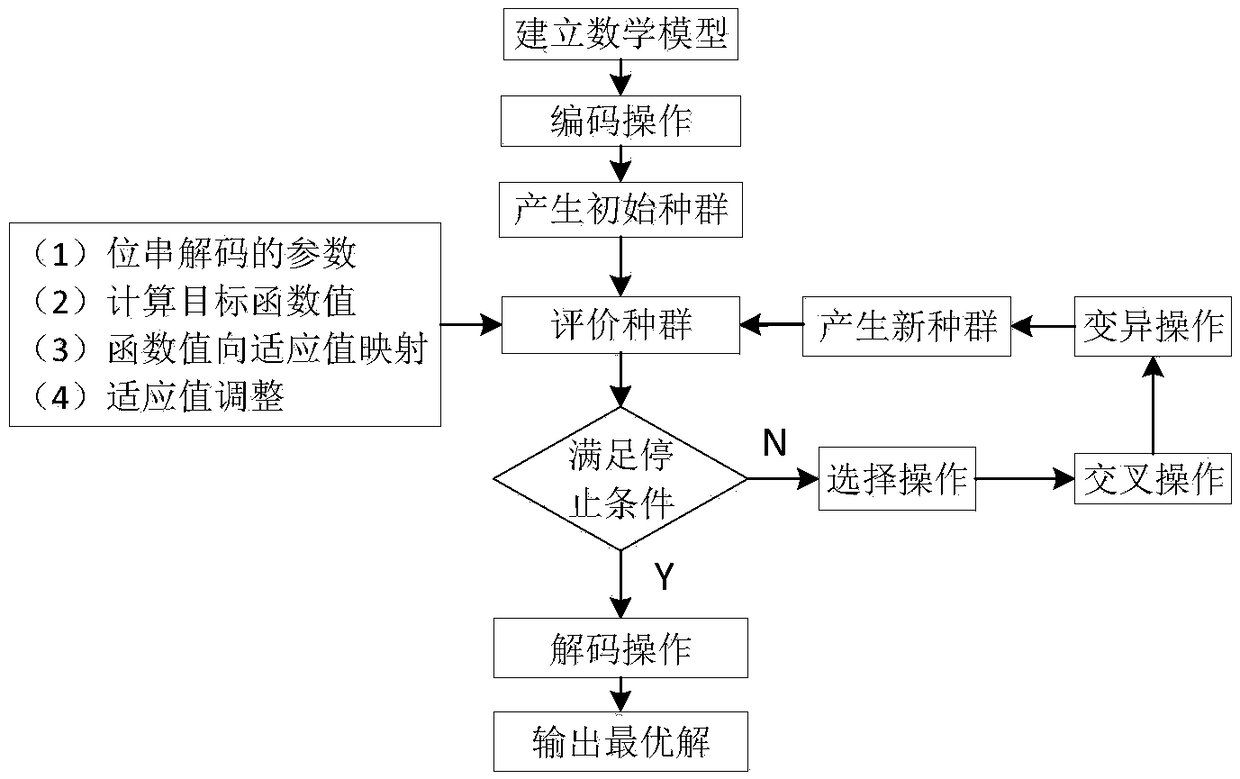

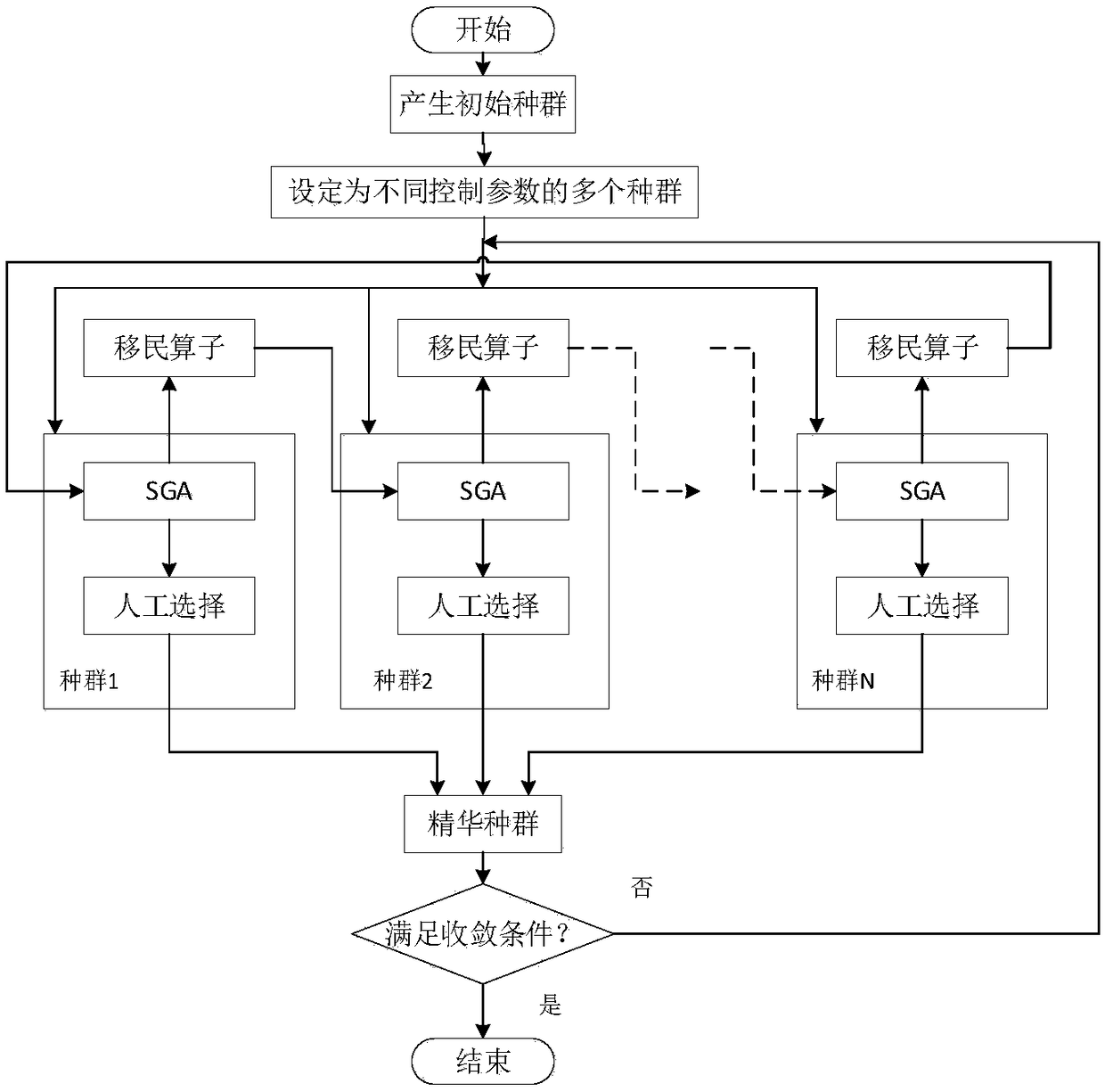

[0059] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. The present invention is a method for precise modeling and multi-objective optimization of workshop layout based on multi-population genetic algorithm. Establish a precise mathematical model of the workshop layout, and use the weighting method to convert multiple optimization objectives into a single evaluation function. At the same time, use the more effective multi-population genetic algorithm to achieve the multi-objective solution of the precise layout model and improve the solution accuracy. Specifically, the following steps are included:

[0060] Step 1: Determine the description of the workshop layout problem and associated assumptions

[0061] The overall layout of the workshop is carried out by using the linear multi-row straight line layout model, considering the space constraints of the actual factory building, and the numbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com