Tension closed loop control method with buffer and system

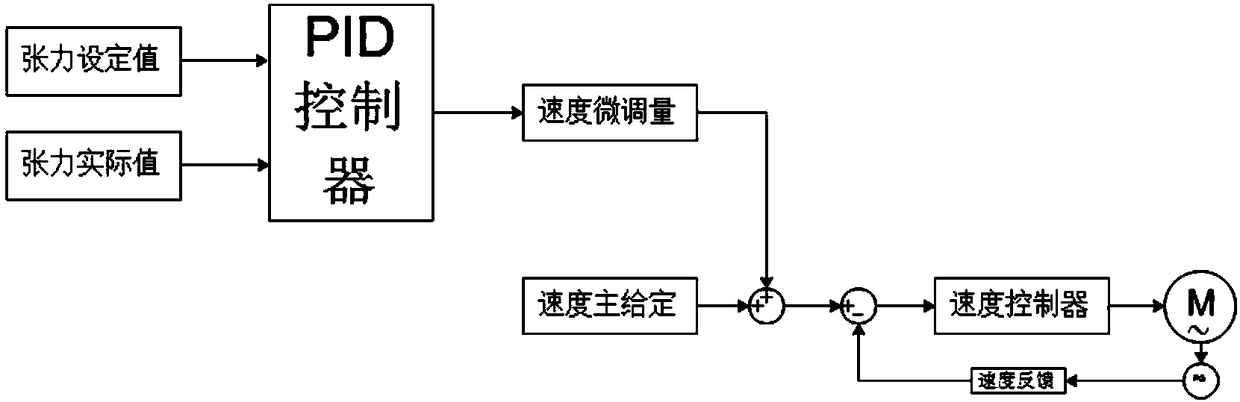

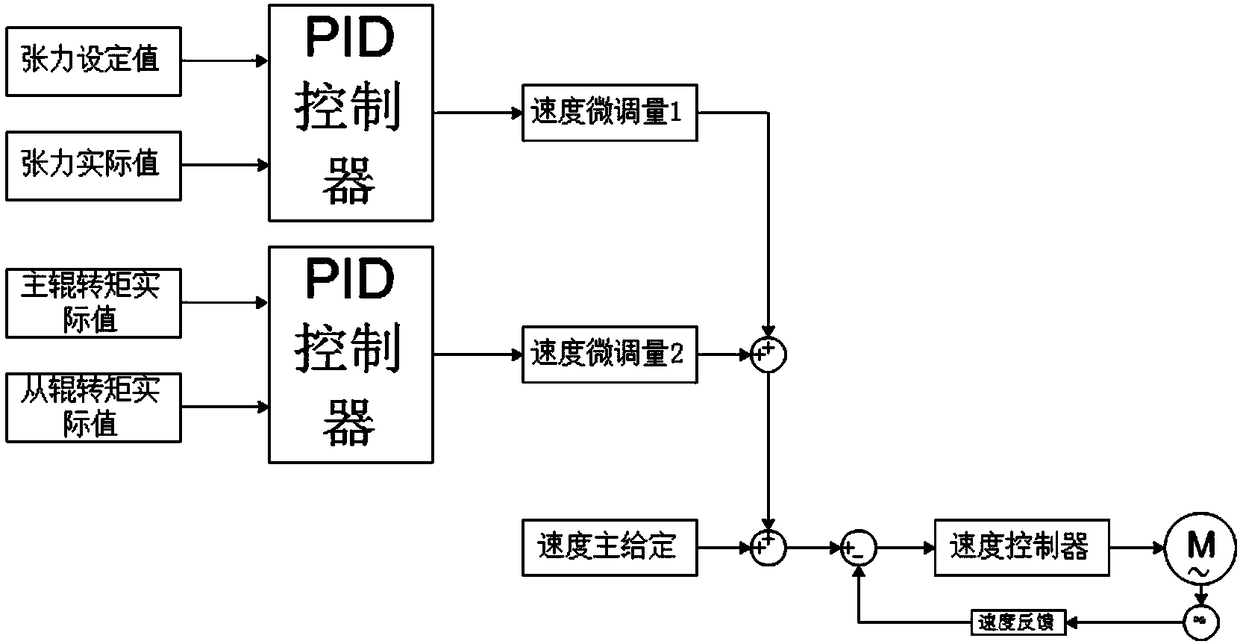

A closed-loop control and tension technology, which is applied in the direction of control/regulation system, mechanical pressure/force control, controller with specific characteristics, etc., can solve the problems of unit shutdown, broken belt in the furnace, strip steel wrinkle, etc., and achieve increased tension The effect of control accuracy and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0044] Please refer to figure 1 , this embodiment provides a buffered tension closed-loop control system 100, which is applied to the strip tension adjustment at the entrance of the galvanizing line, and includes a tension roller group 1, a tension stabilizer 2 and a furnace front tension roller 3 arranged in sequence.

[0045] In this embodiment, the tension stabilizer 2 includes a first turning roller 21, a buffer roller 22, a second turning roller 23 and a driving mechanism. The buffer roller 22 and the second diverting roller 23 enter the annealing furnace through the furnace front tension measuring roller 3. The cooperation of the first diverting roller 21, the buffer roller 22 and the second diverting roller 23 can adjust the tension of the strip steel and relieve the tension of the strip steel. Due to the influence of tension factors in the furnace, the driving mechanism is connected with the buffer roller 22, and the buffer roller 22 is driven to move along the forward...

no. 2 example

[0054] This embodiment provides a buffered tension closed-loop control method, including:

[0055] At the exit of the looper at the entrance of the galvanizing unit, the tension roller group 1, the tension stabilizer 2 and the tension roller 3 in front of the furnace are arranged in sequence;

[0056] Tension roller group 1 close-loop adjusts the tension in front of the furnace;

[0057] The tension stabilizer 2 closes the loop to adjust the tension in front of the furnace.

[0058] In the step of "arranging and distributing the tension roller group 1, the tension stabilizer 2 and the tension measuring roller 3 in front of the furnace in sequence at the exit of the looper at the entrance of the galvanizing unit", the strip passes through the tension roller group 1, the tension stabilizer 2 and the furnace front in sequence. The tension measuring roller 3 enters the annealing furnace, and the tension measuring roller 3 in front of the furnace is provided with a tension sensor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com